Thanks very much for the replies. The link to the patent applcation and to the Narex manual were very interesting and have been duely downloaded and saved.

I'll have to look harder on Youtube. The video I watched was dismantling the UPA3 and was in German. Annoyingly the 3 and 4 have significant differences.

The UPA4 does have a limit stop on facing although it doesn't seem to have automatic return or reverse. I know this worked in the past, but haven't used it recently.

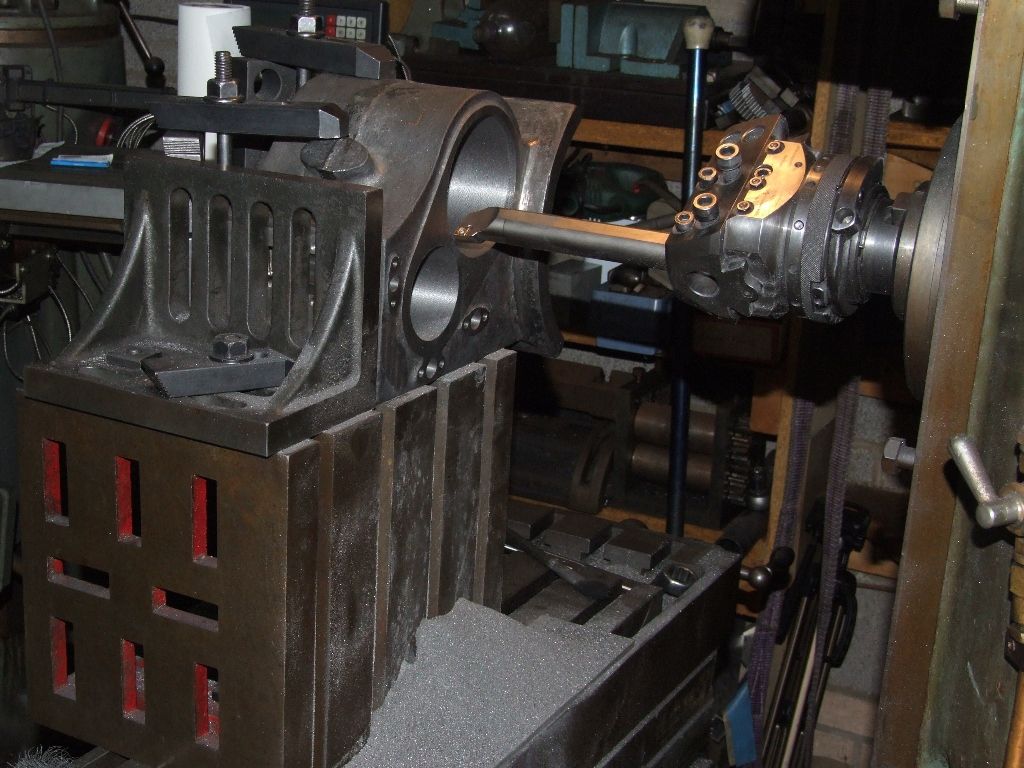

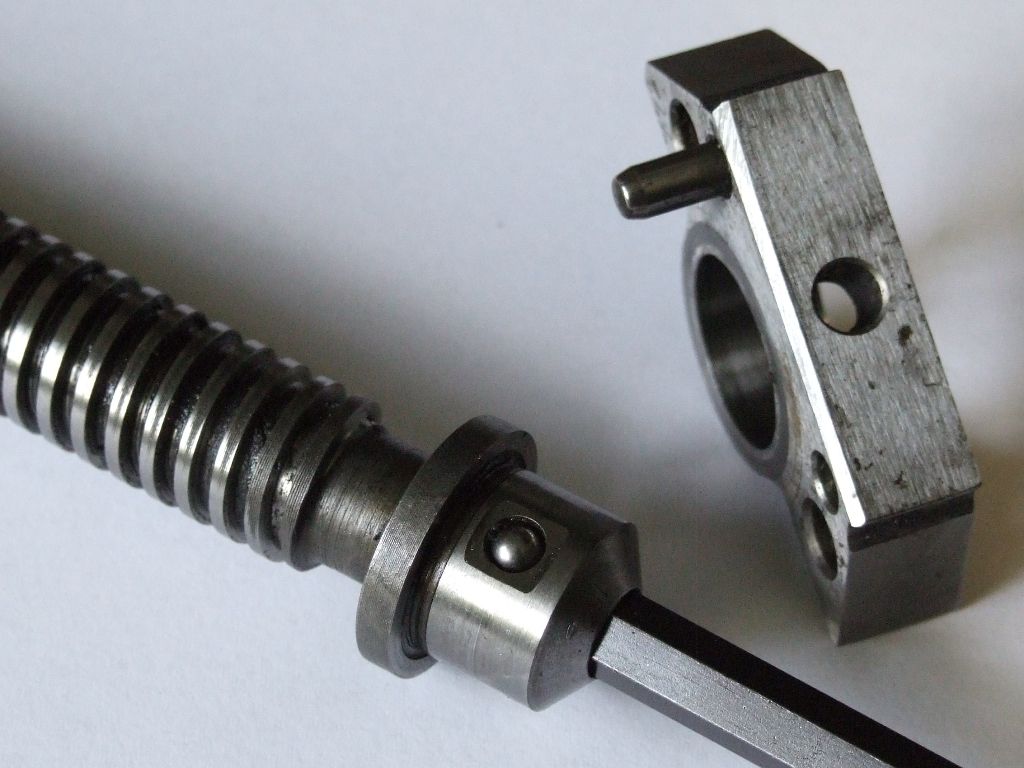

My current thinking is as follows. The coarse feed is simply a screw and nut as per most boring heads. The fine feed (and facing) is via a worm and worm wheel on the coarse feed screw. Clearly if the worm wheel is locked to the screw then the coarse adjustment will not be able to turn the shaft against the fine feed worm. Ergo there must be a locking mechanism, or clutch, on the worm wheel. This leads to two possibilities. One, the mechanism isn't working properly or two, I'm not using the feeds properly. Although the manual isn't explicit it would make sense that you can't mix 'n' match between coarse and fine feeds. Logically one would use the coarse feed first and then engage the fine feed for final adjustments. If the coarse feed is then used again it would disengage the fine feed.

So the plan is to one, spend some time playing with the controls and see if I can get fine feed, and facing, working in a logical manner. I'd better oil the internals too. If I can't get the fine feed working consistently I'll have to take the head apart.

Andrew

Postscript: I've a nasty feeling I'm going to end up taking the head apart come what may if only to satisfy my curiosity.

Chris Evans 6.