Posted by Simon Williams 3 on 19/05/2020 22:43:02:

That snugging nut is a left hand thread – so I agree you are turning it correclty to push against the end of the quill, but is it moving? Can you turn that backing nut with your black spanner in the opposite direction at all?

That really looks like it should let go.

You need to move the snugging nut away from the end of the quill to create a space into which you can get a couple of slotted taper wedges between the back of the chuck and the end of the quill.

………………………………….

Rgds Simon

Gents, I'm struggling to get a handle on this, so to speak.

As several people have mentioned, that ring with the C spanner holes is on a Left Hand thread.

As such, in order to make it bear against the end of the spindle, the nut must be rotated Anticlockwise, as viewed from the cutter end of the chuck.

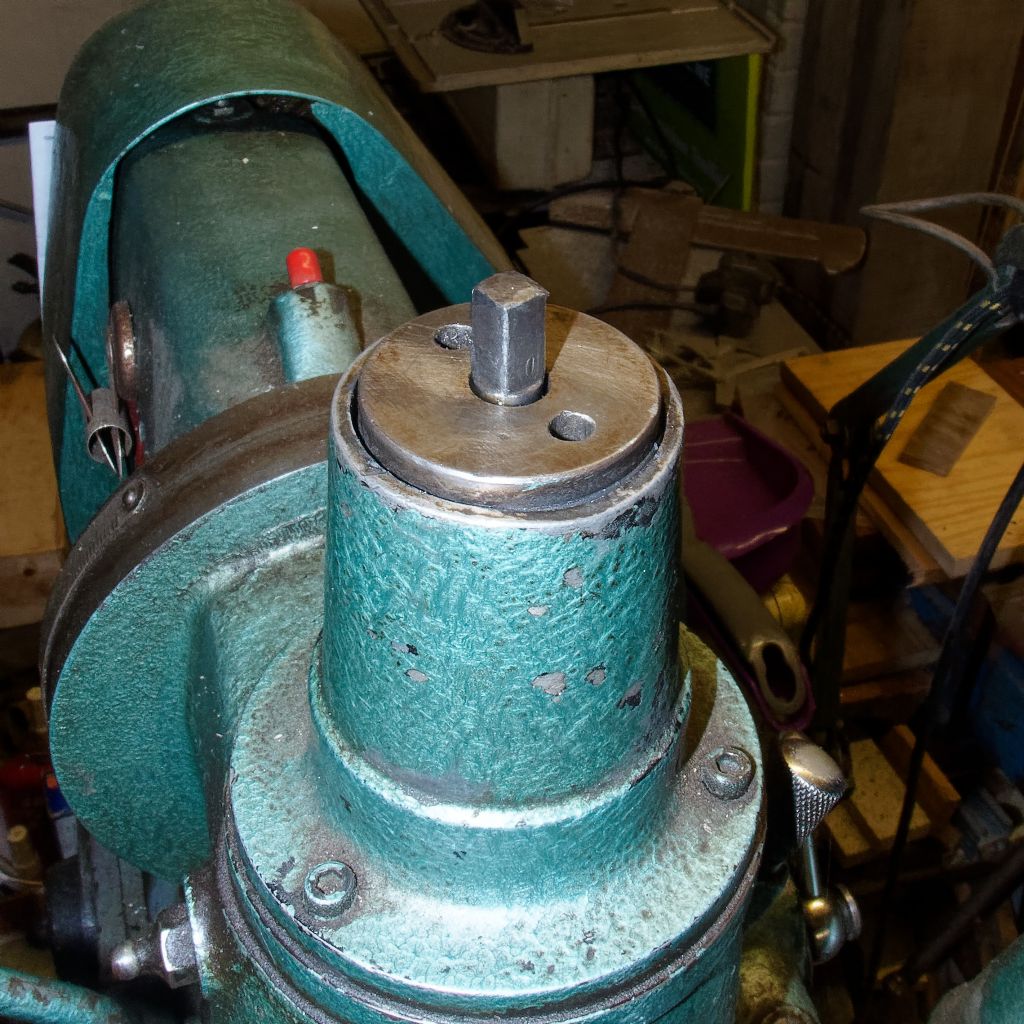

Please see the photo below for the correct placement, and turning direction, of the C spanner ( though a better spanner would clearly be advisable ).

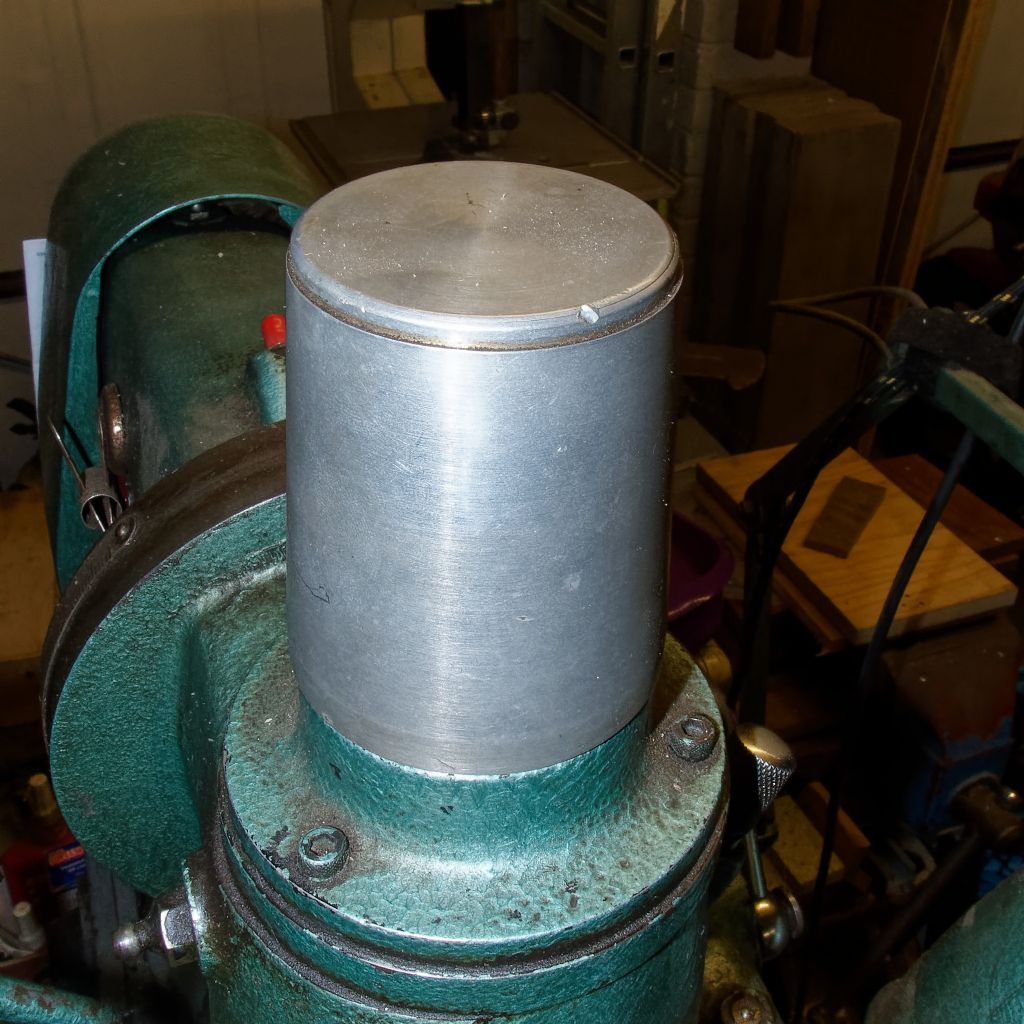

I know this is the correct orientation, as I've just used it to release the chuck from the lathe spindle, as per the photo below.

Yes I know it's the wrong C spanner and everything needs a clean, but this was a quick setup on the Warco 720 for illustration purposes.

I set it in the lathe rather than the mill so the spanner stayed in place whilst I took the photo.

I'd suggest that there is only a very small gap between the collar and the spindle end in Avon's case, so there might not be enough space for wedges.

Assuming the nut isn't now jammed on the chuck, through turning in the wrong direction, pre-load the nut hard (with a small hammer) against the spindle end and then try clouting the remaining end of the drawbar with a decent sized hammer.

Perhaps protecting the drawbar's end with a lump of copper or brass might be a good idea (and it would also protect the screw thread on the spindle's end if anything moves.

N.B. even just fitting the chuck to the lathe spindle with just a reasonable rap, it took quite a bit of force on the spanner to remove the chuck in the photo shown above, as the morse taper locked quite well.

I'd suggest that using the nut alone won't be enough axial force to eject the chuck, but the preload might be enough when used with a hammer on the drawbar.

Bill

Edited By peak4 on 20/05/2020 11:47:28

Ben atkinson.