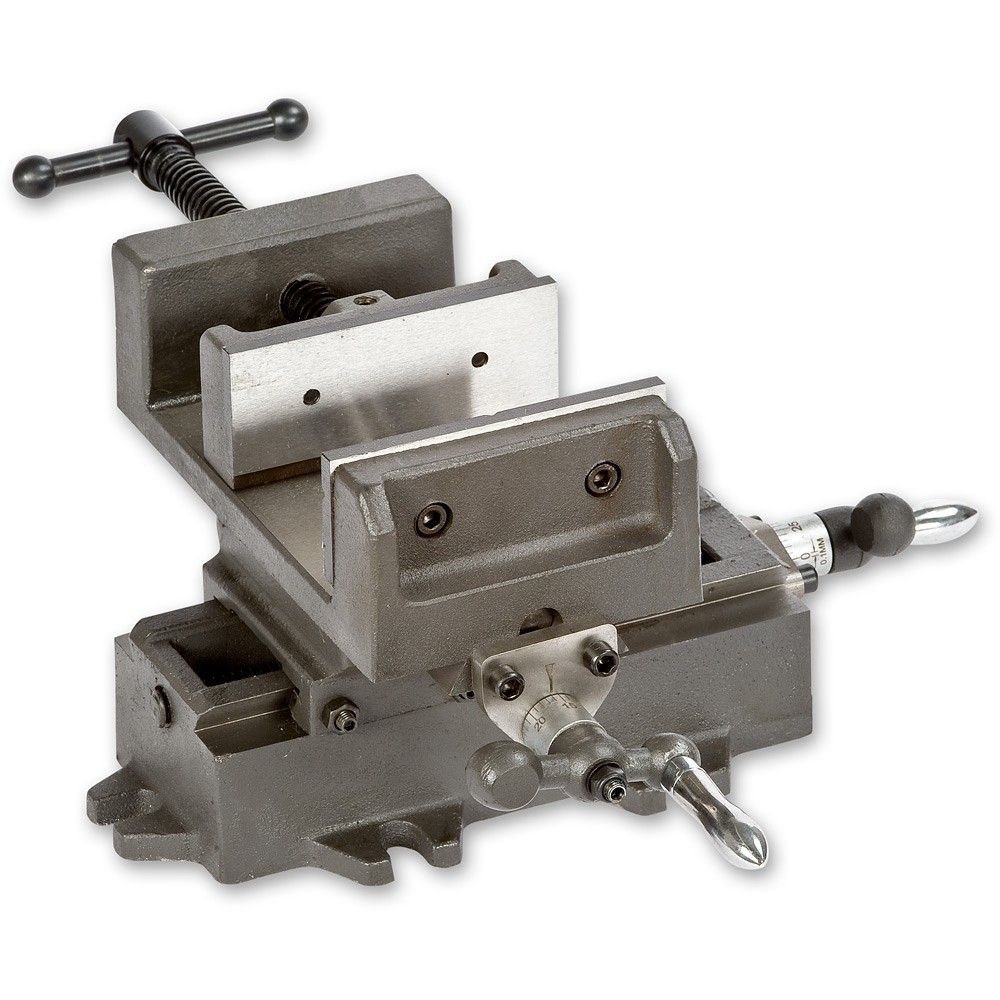

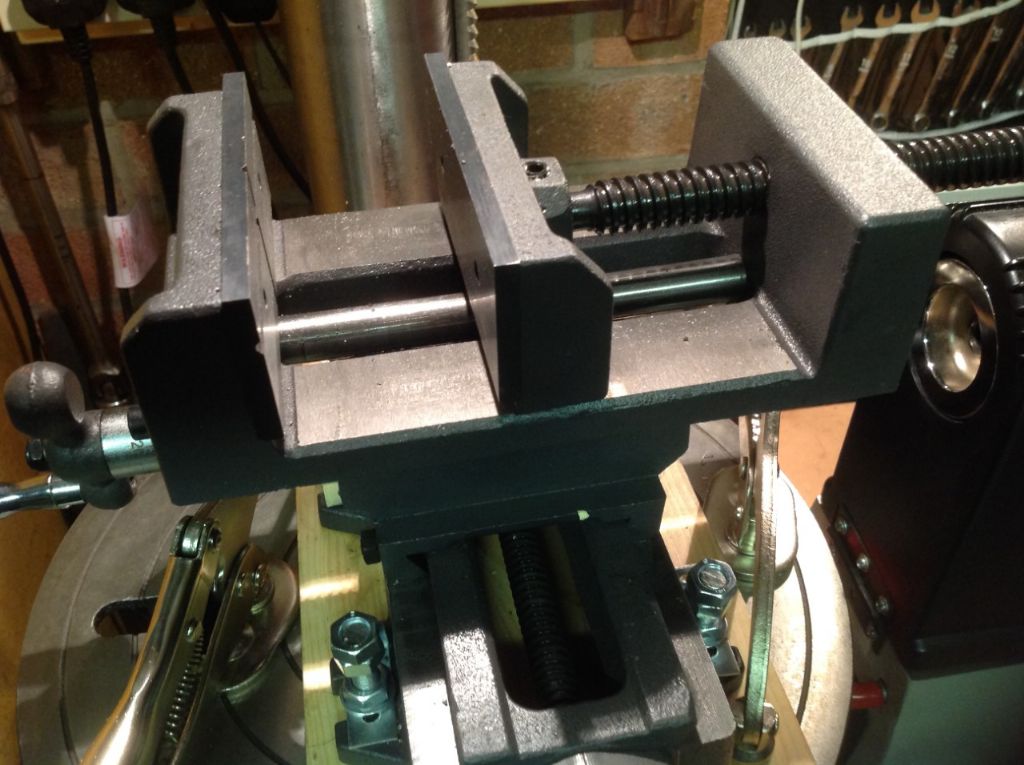

Looks like I'm on my own as being respectably satisfied with my cross vice. As mentioned earlier mine is an older 6" version which appears to be bit more substantial than the later types and has a rod type guide for the moving jaw.

Yes the screws are sloppy and the gibs not wonderfully precise but it is what it is. An effective device for moving parts around to bring them into alignment with the drill before making a hole in the right (we hope) place. With the thumb screw locks tightened up it holds quite securely enough for any sane job.

OK its not a proper X-Y table with precision, graduated screws. But at the price I paid, £60 – £70 from memory many years ago, any such expectations would have been totally unreasonable. I was a little disappointed by the general fit and slop but it worked. One thing I did have to do was swop the hopeless plain, smooth, flat vice jaws for a pair of prismatic type. NuTool brand so no longer around but no doubt similar can still be found. One horizontal Vee groove and three vertical ones of different sizes. Turned a dubious in the extreme device into something eminently useable within its limitations.

Proper co-ordinate drilling gets done on the Bridgeport which has a 3 axis glass scale DRO set fitted.

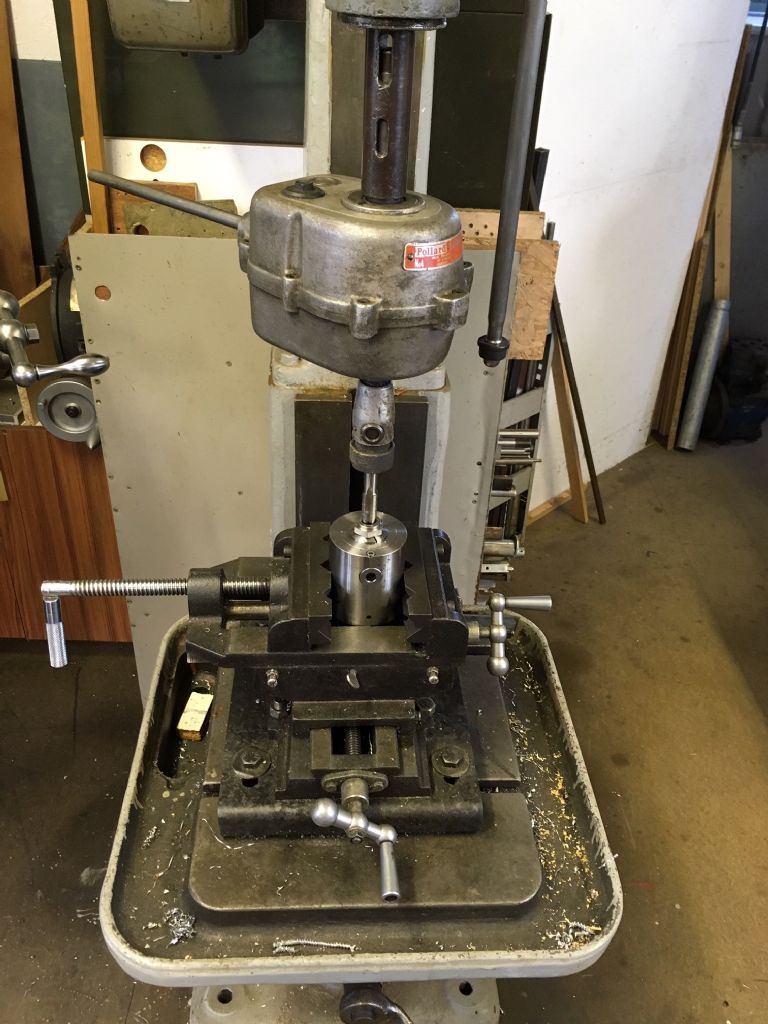

Here is a job we did this afternoon.

Hollow stainless steel oil union around 25 mm long with 27 mm AF hex and M23 x 1.5 external threads held in a 5C collet about to receive an M16 x 1.5 through tap. Pollard No 4 tapping head driven by Fredr'k Pollard 15 AY drill put the tap through "just like that". Two done in a couple or three minutes. Cross vice locked up by thumb screws in both axes didn't even blink.

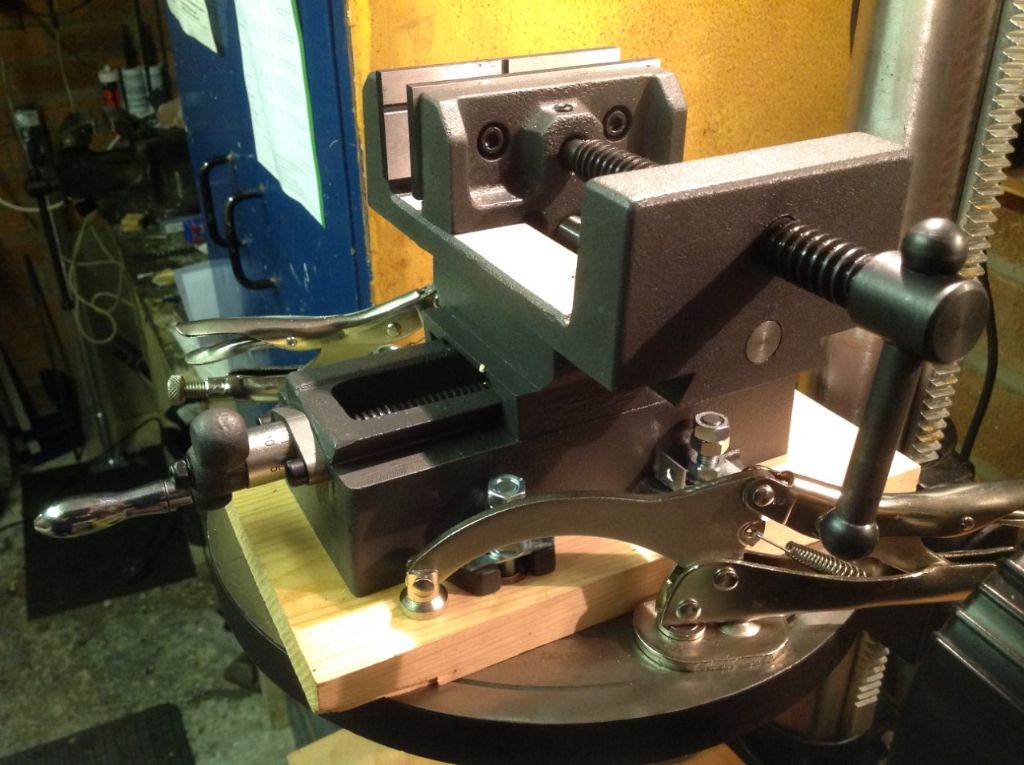

The vice pretty much never comes off the big 15 AY drill. Maybe one or twice a year. Normal configuration is with a flat "improved wood" table held on via a wide batten underneath.

Ideal for sheet or many smaller components that can be held down by a few strategically placed twin thread screws zapped in with a battery drill. Or clamp to the overhanging sides with G, tool or friction type trigger clamp. Have a smaller one too for similar work. Easily removed when I want to use the naked vice.

The plate shown is probably past its best but I have a stack of old kitchen furnishing panels up in the shop attic to make a new one from.

Clive.

Edited By Clive Foster on 18/01/2019 22:15:06

Clive Foster.