I've been having a bit of a play this afternoon as the weather wasn't up to much.

Rather than hijack the other thread, which was asking specifically about the Sealey SMS2008 drill sharpener, I thought I'd start a new one for a quick comparison.

Maybe others could contribute some ideas and photos to this thread, so that it could be used for reference and learning.

Doubletop-Pete commented, in the above thread, that he felt that his Sealey was taking off too much metal; so was mine out of the box, albeit a second hand box.

Sliding the wheel towards the motor, will reduce the depth of cut on the primary grind, as it's a tapered wheel.

It's a bit of a fine line as moving the wheel also affects the split point grind.

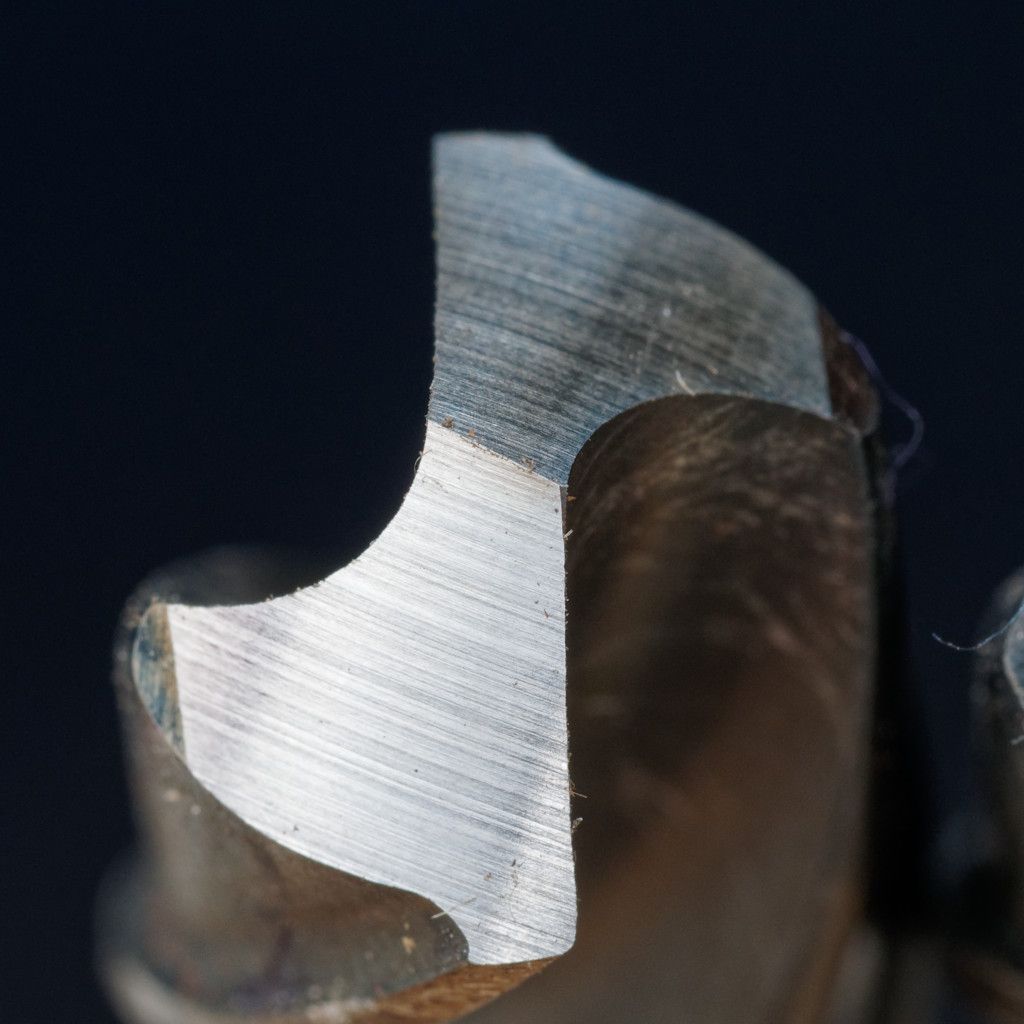

As you can see from my efforts, I've not quite got it right yet, but even 1/2" bits ground like this, will start off without a pilot hole or centre pop, though I accept the latter's bad practice.

Sorry about the quality of the photos. I was trying to do it in natural light in the conservatory, but it was starting to get a bit dark.

The whole project took rather longer than planned

I sharpened several 1/2" bits using;

A Sealey SMS2008,

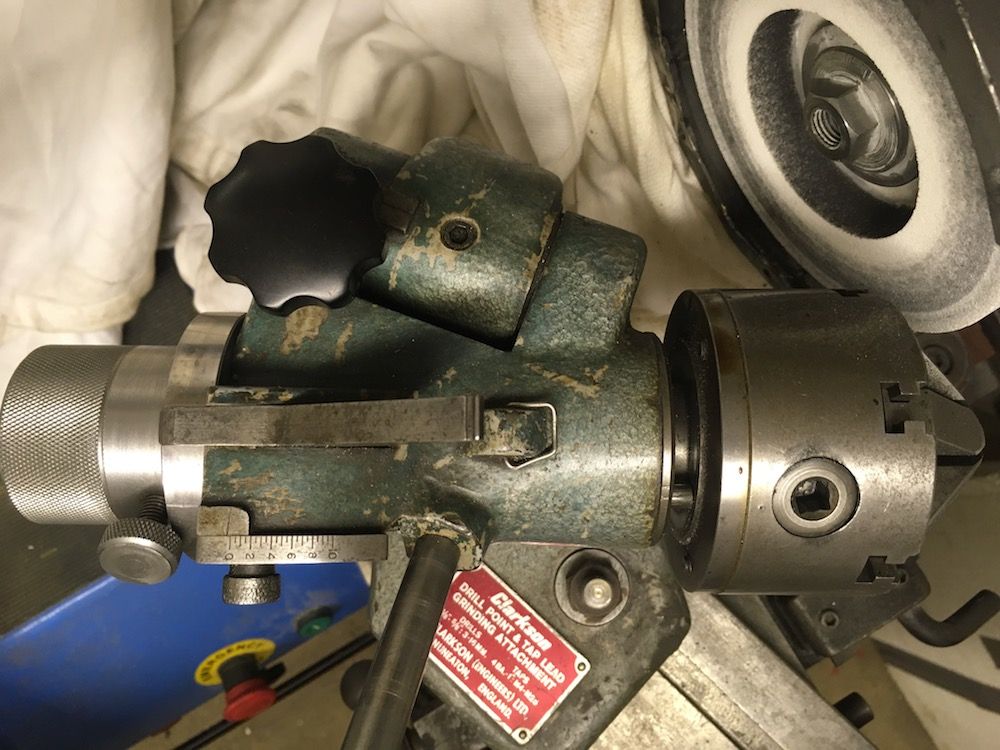

A brand new genuine Picador jig; Note that the Picador jig has the vertical pivot, and in theory at least, should work OK out of the box. Drill bit orientation is set by a movable detent on the flute to be ground.

I used 1/4" projection beyond the end of the jig, as recommended for larger drill bits.

It's a different geometry to the various clones with the tilted pivot.

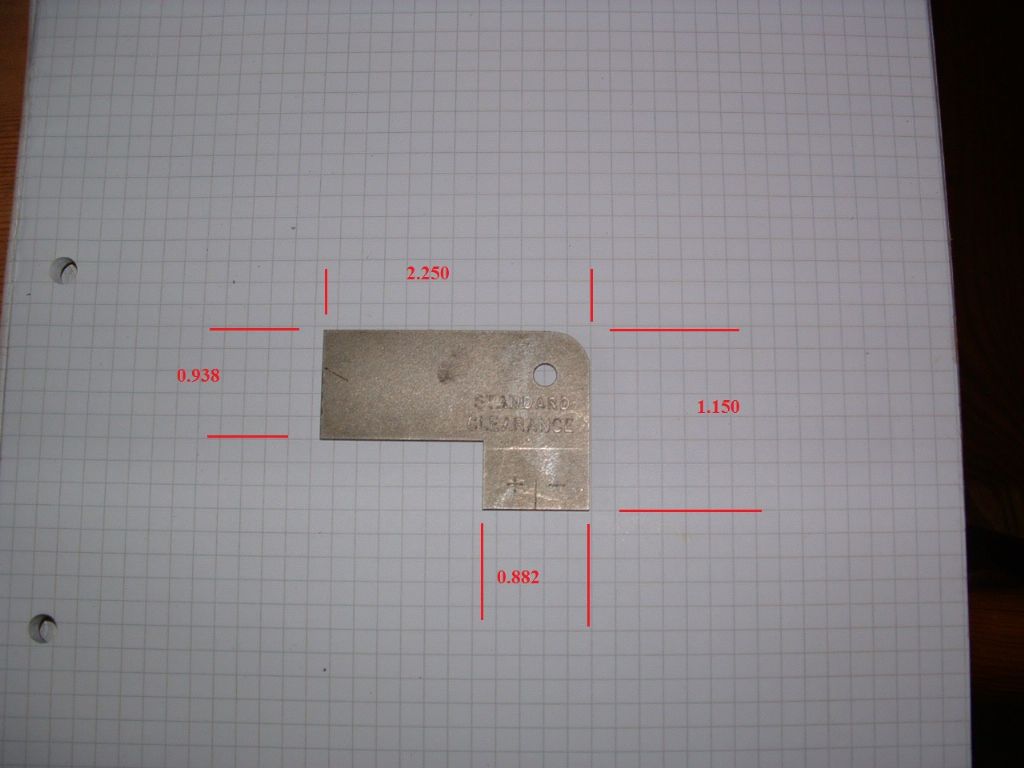

A Reliance No.2 (which needs the bit cutting edge setting by eye). On this one it's recommended to use a projection of three times the drill diameter, so in this case 1 1/2"

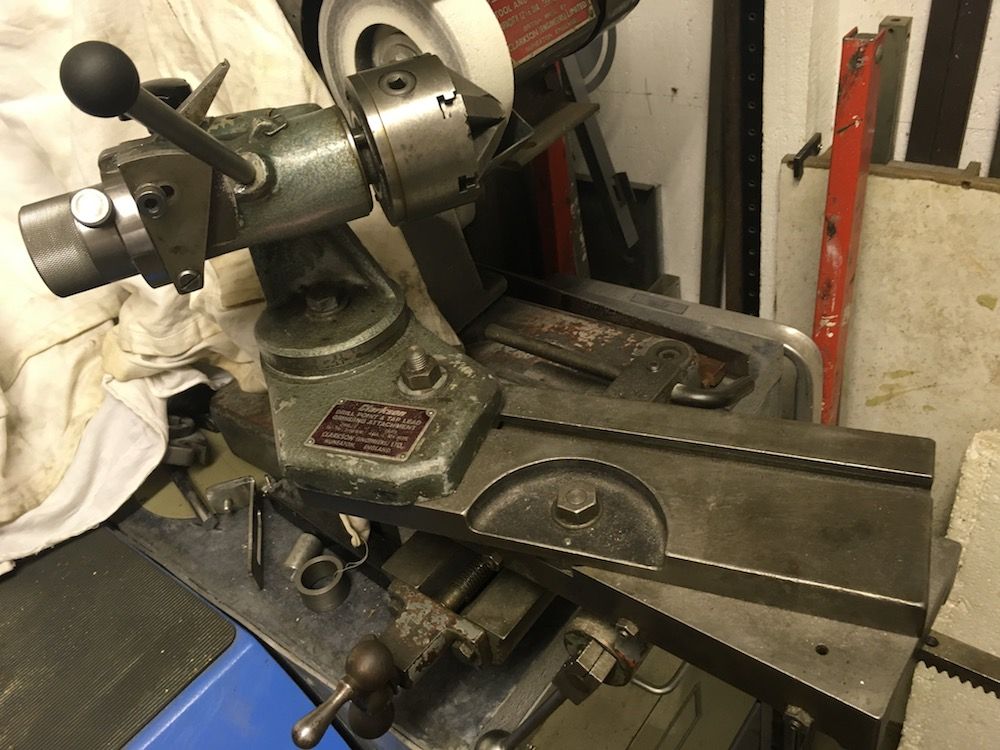

The two jigs (Picador and Reliance) were used on a cup wheel on a Clarkson cutter Grinder. (As you can see, the wheel's a bit coarse really, but it's all I had available at the time.)

The new Picador had a bit of play in the mounting foot, as it's only held together with a cask Mazak name plate, so I temporarily nipped it up a bit with a little toolmakers clamp.

I don't claim to be any expert at drill sharpening, but am generally considered reasonably dexterous. I'm sure many on here get perfect results freehand; I know can't

Left to Right, Picador, Sealey Split Point, Sealey Plain Grind, Reliance, New Unknown Make, New Unknown Make Four Facet, and lastly a New Presto 7/16" ( I didn't have a new 1/2" one).

The middle one, ground on the Reliance, was an older Morse tapered one which doesn't look to have had the flutes ground very well from new, hence the odd side view of the relief.

Side View;

Top View;

Picador;

Sealey Split Point;

Sealey Plain Grind;

Reliance No.2;

Unknown Make New(ish) Commercially Ground;

Unknown Make New(ish) Four Facet Commercially Ground;

New(ish) Presto 7/16" (enlarged to similar size for comparison);

Edited By peak4 on 26/12/2018 17:19:39

Neil A.