The size of the pins? Measure the holes afterwards. Having dismantled one of mine recently to fit copper jaws (the screws, 1/4 BSW around 3/4 inch long were very stuck and needed spotting with an end mill, then left hand drilling on the mill with one requiring heat to remove)

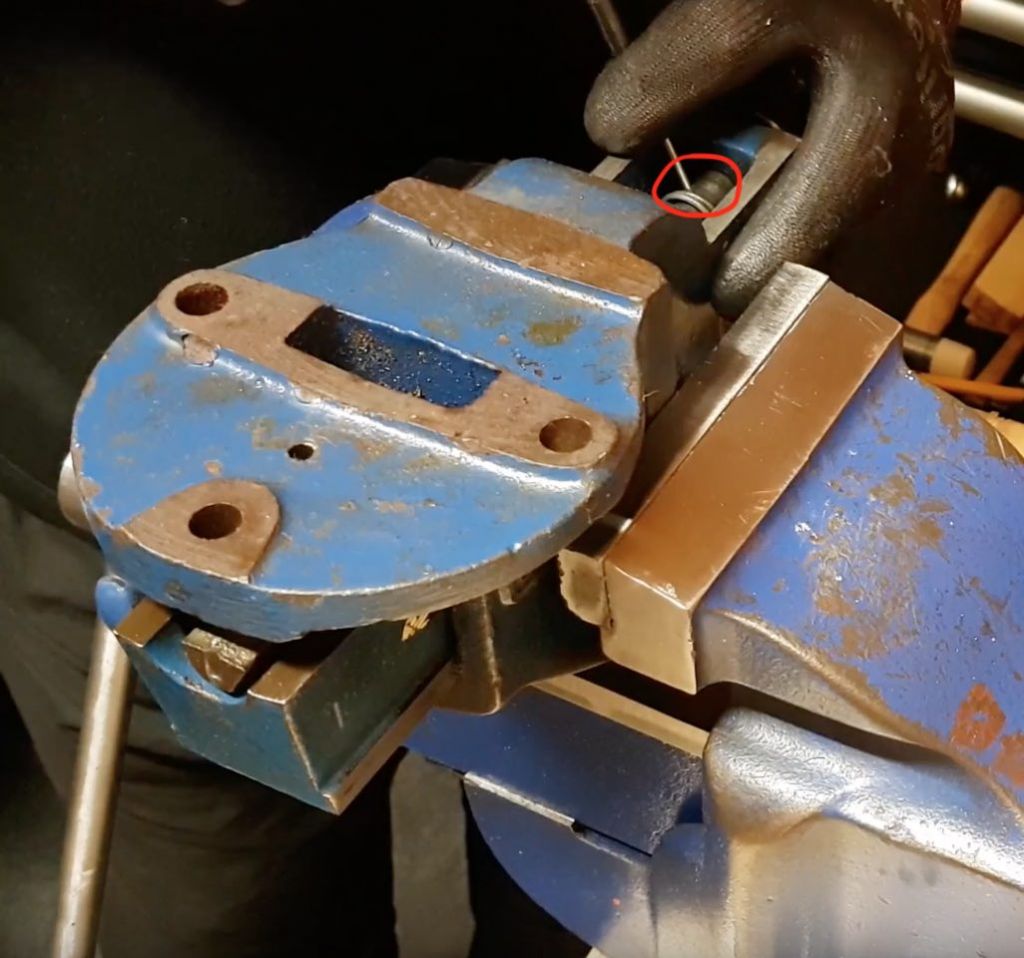

The pin holding the nut into the main body at the rear of the vice is somewhere around 3/16", the one on the screw a bit smaller, possibly 5/32", but they could be metric, I never measured and simply refitted the ones I removed.

Besides the slight variation in taper (1:48 &1:50) metric pins are measured at one end, imperial ones at the other and at the moment I can't recall which is which.

Removal? parallel pin punch, hit with a copper & hide mallet, not much force needed at all,

The one on the screw will catch you out if you drive it through too much and jam up the screw and prevent if being turned, so partial drive through, rotate the screw 180 degrees and pull out the pin with a pair of pliers / mole grips etc is the better option.

Martin 100.