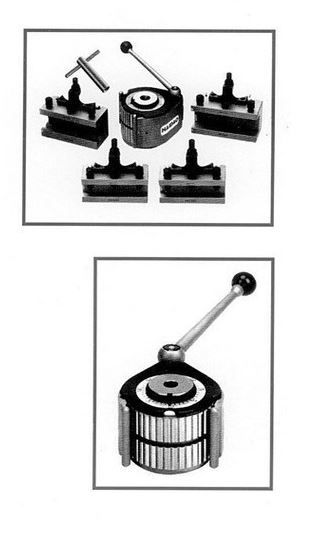

As expressed in another thread, I'm fed up with the aluminium QCTP I got for my SPG0618A. (Real Bull 7×14).

It's a piston type and deforms easily.

So I'm planning to build my own. I've had an idea for how it should work, but there could be any number of reasons why it's a poor idea. I'm hoping that the collective can expose them to me before I start making swarf!

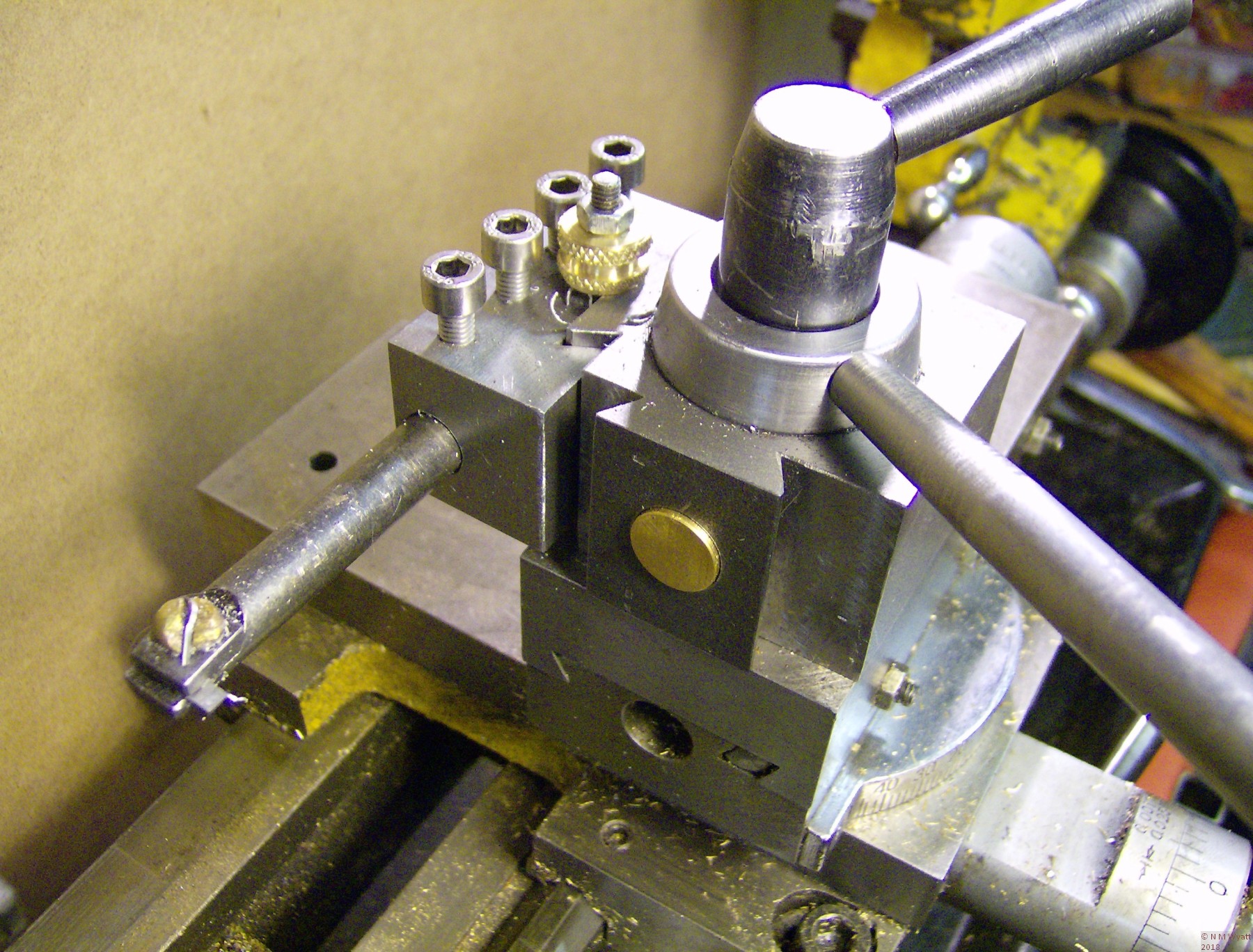

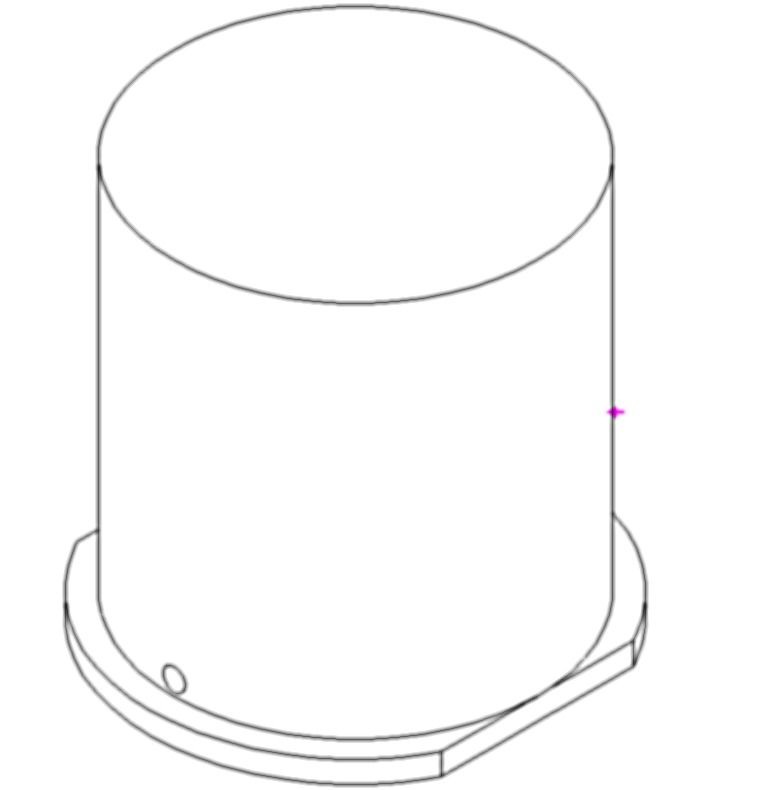

The toolpost base on the topslide is 50mm square with an M10 thread. Standard stuff,.

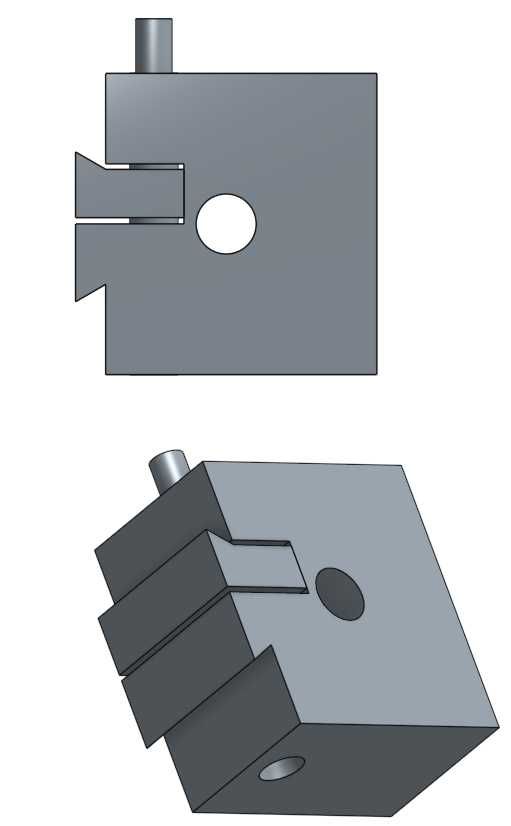

The basic idea is to have the dovetails pull in to the toolpost not push out. In the image below the tool would be pointing downwards. The rod at the top, would be threaded with a nut on it pulling the moving dovetail up. I'd put a pin through the moving dovetail and bar.

I'd make the bar and the bore a tight fit to restrict the movement of the dovetail to lateral only.

Toolholders would be the same shape as the current piston based ones albeit steel and perhaps slightly different dimensions.

My concern is the rigidity given that there is quite a small volume of metal between the central bore and the trough for the moving dovetail. An option would be to bolt plates top and bottom.

I'd clearly need two dovetails so that both turning and boring tools can be supported

Any views would be welcome!

Iain

mark smith 20.