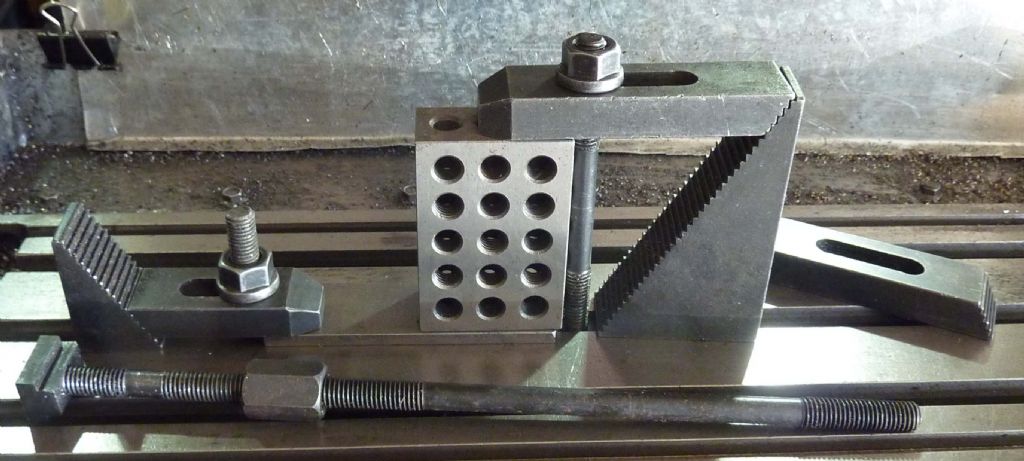

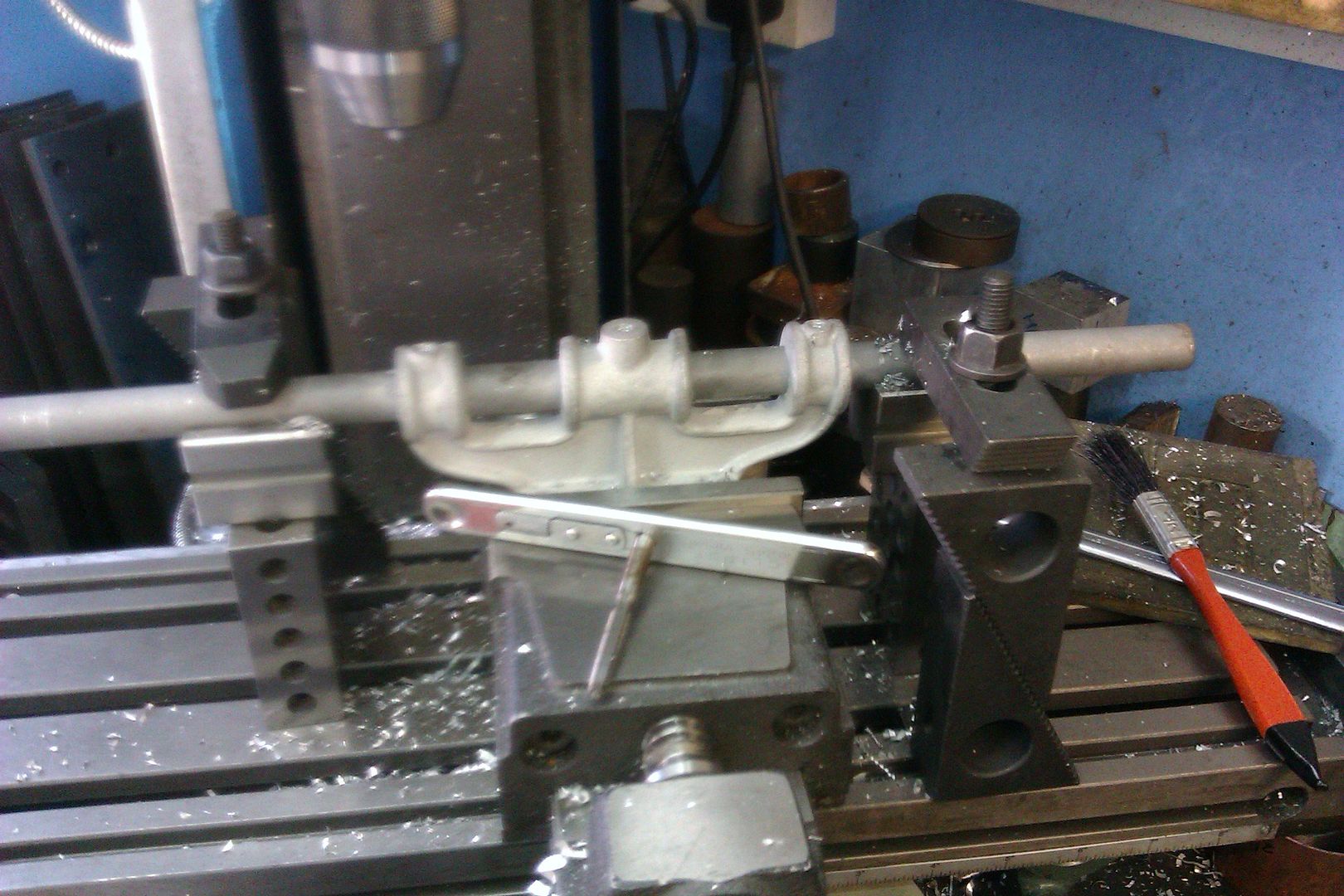

I have the problem of buying a retired toolmakers dore westbury. He made just about everything himself. I've managed with this type so far and I can understand why he made them – they can be rather expensive to buy. They are heat treated, 3/8 thick and 3in long. There is also some smaller stuff.

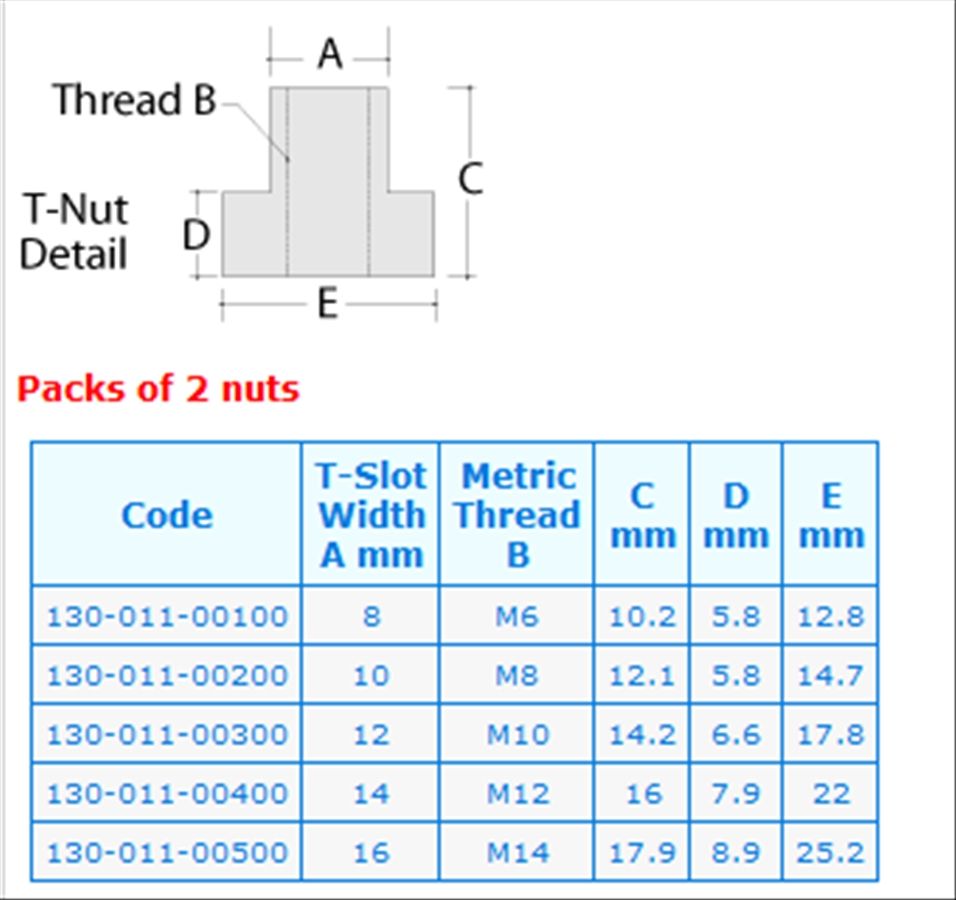

As these work rather well I didn't really want to buy a set but the prices buying bits and pieces work out far more. He made a number of clamping bits and pieces for it but the studs are a bit of a mess. I could fix that via high tensile all thread. For some reason he settled on 5/16 bsf for studs. The T slots may be metric, M8 I suspect but M6 is available in the same size of T. I'd guess he had something else about and 5/16 fitted both. It's easy to make T nuts, a strip at a time and then saw them off.

The reason I wondered about setting the height on the step blocks and the angle range of the stepped clamp is that I did use the blocks briefly and from memory the steps are angled so that they pull together rather than slide apart. I assume the clamps with the steps on the end are the same so past some angle they wont pull together. When the clamp isn't level spherical washers should be fitted as well but I suppose that's really only needed for rather powerful millers but suspect I might get some of those.

T nuts are sold threaded all or part way through but at a couple of quid plus each where I have seen both styles offered I don't think I will be buying any,

John

–

Ajohnw.