After reading the article in the Autumn 2009 issue of M E W, I made one. Was so impressed that I made one for a pal.

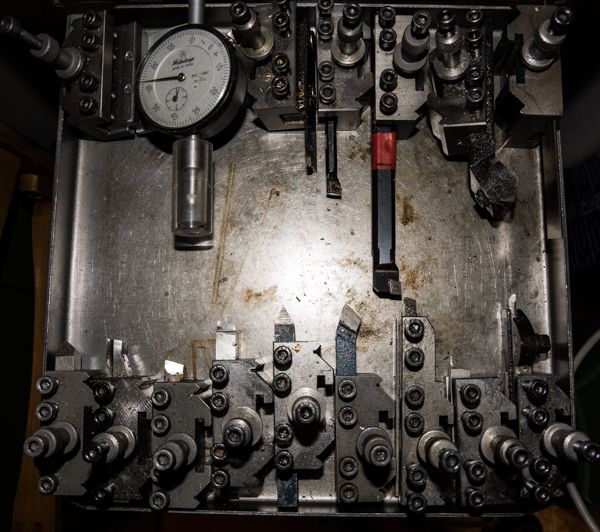

Mine never was used much in anger, (reverted to replaceable tips) but a few months ago, made a bigger version to take 5/16 toolbits.

This has now become the standard tool of choice. Nearly as good as replaceable tip, (better at interrupted cuts), easy to set to centre height (using a gauge), and a lot cheaper than T.C. tips.

Initially used the 20 degree sharpening jig as per the article, but have made up a holder for the Worden. This makes a better job of it, but takes time to dig out the Worden from under the fitting bench and set it up. "Do I hear someone say "you get what you pay for?"

Am now wondering about making a L H version, (scrooge!) or maybe even buying one.

Conclusion: Either way; recommended.

Howard

Vic.

Vic.