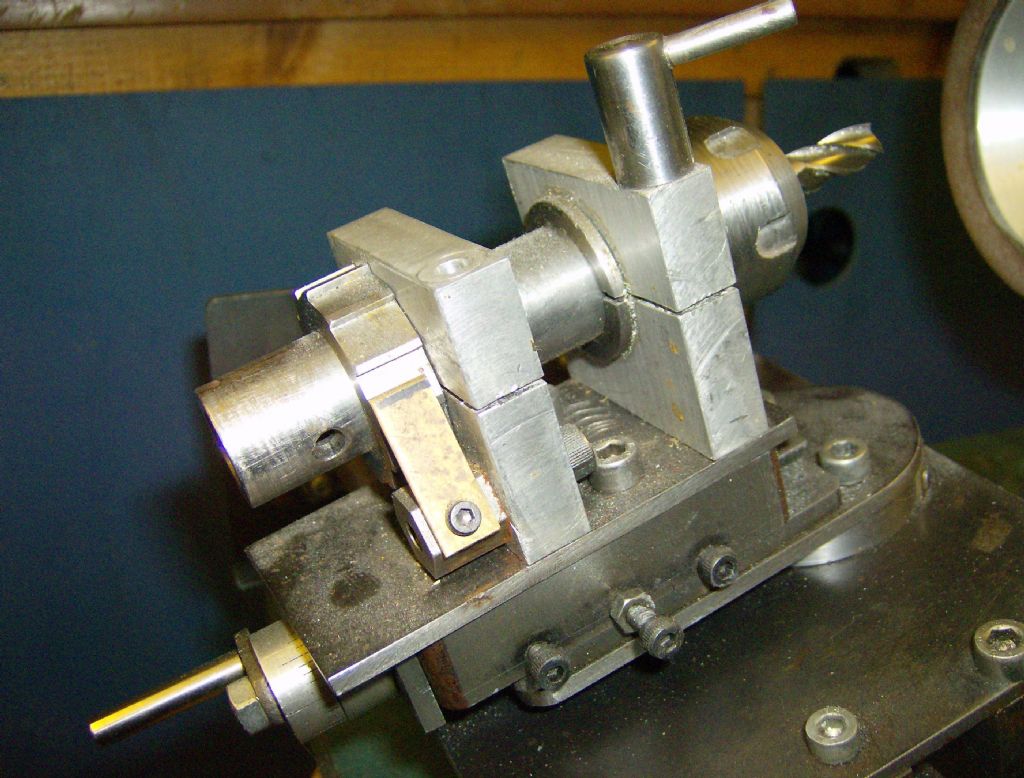

These all look like workable solutions to the basic problem, yet all different  You chaps are obviously typical Model Engineers – inventive problem-solvers. Makes me feel I'm being lazy in looking for an off-the-shelf solution.

You chaps are obviously typical Model Engineers – inventive problem-solvers. Makes me feel I'm being lazy in looking for an off-the-shelf solution.

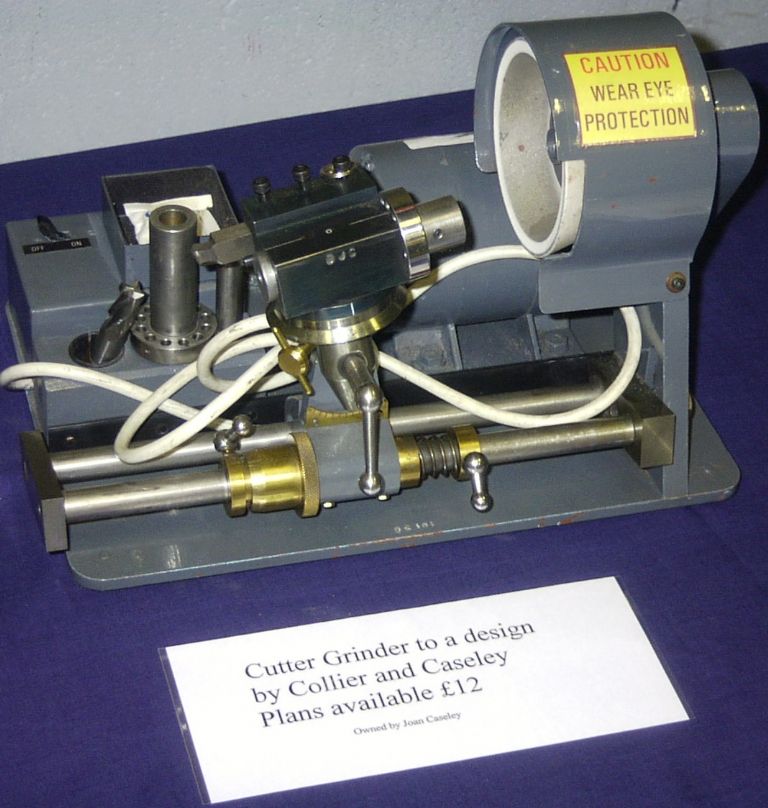

I can dedicate an area about 2ft square to accommodate the whole thing, anything larger would start to get in the way of other tools so the more compact the better. I was originally looking at the little Universal Tool and Cutter Grinder sold by (amongst others) RDG **LINK** which fits the size requirements but has not received particularly good reviews (and sells for less than half the price in the US). Pity that, but it wouldn't do any more than most of the solutions described above anyway. I suspect in the end I will cherry-pick the ideas and features found in the designs invented by others and from that cobble together something that suits my needs.

Thanks for all the suggestions!

Ian P.

Ian P.

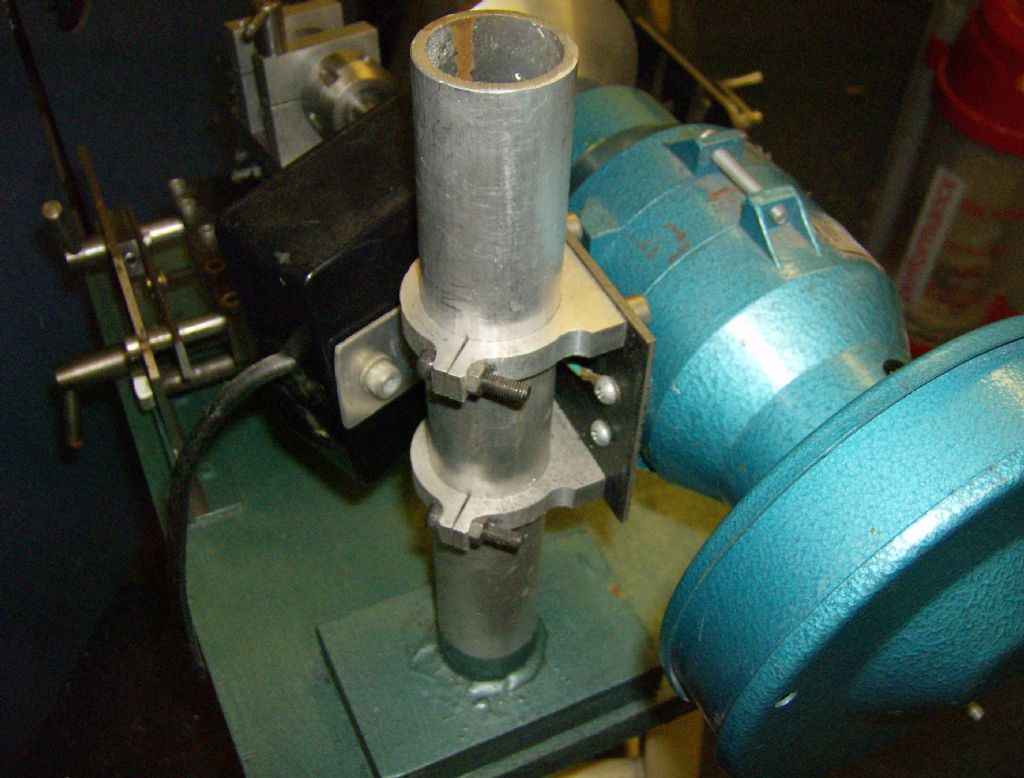

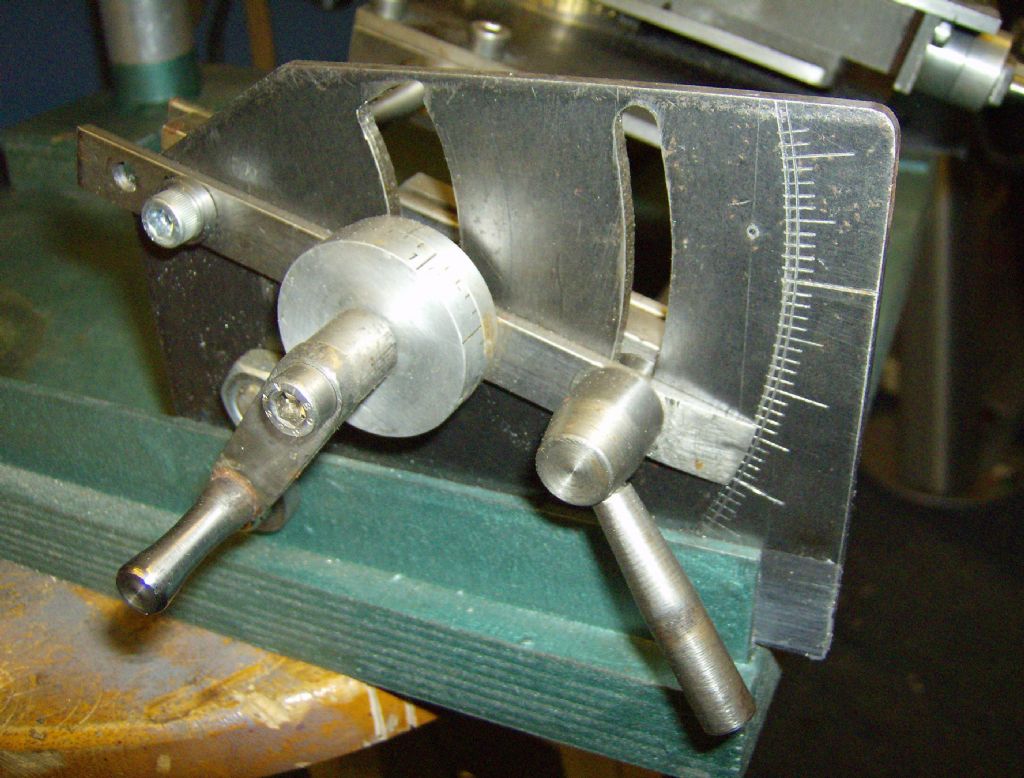

there are some interesting features in it though. I don't think it would take a year to make a Quorn but maybe owners could enlighten me.

there are some interesting features in it though. I don't think it would take a year to make a Quorn but maybe owners could enlighten me.