Good evening all

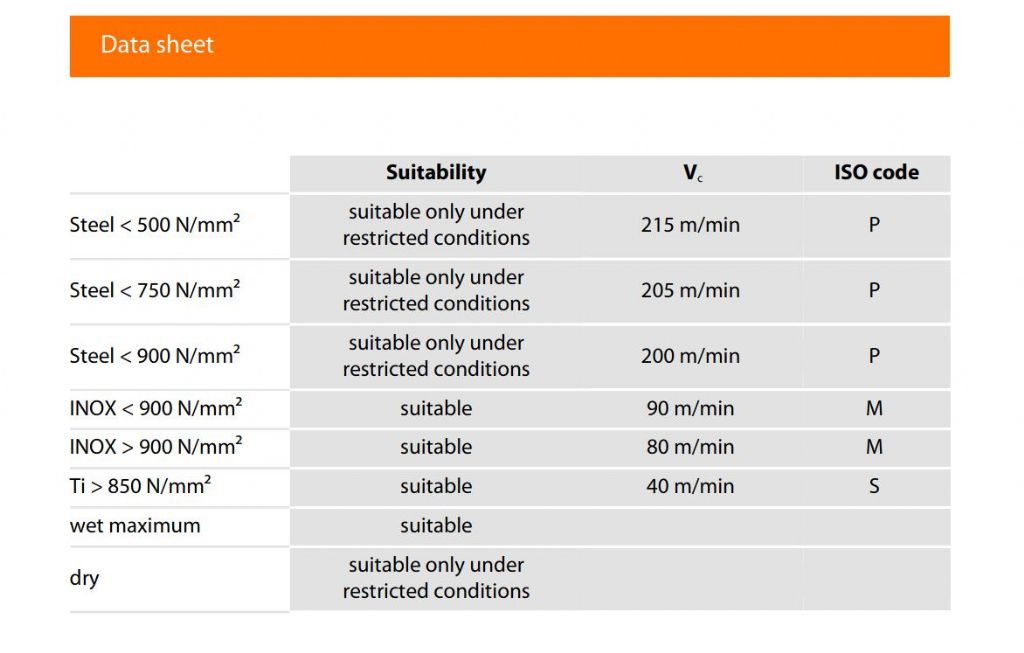

Thinking my machine was up to the task, I bought a 50mm 5 insert SEKT face mill to use on some cast iron.

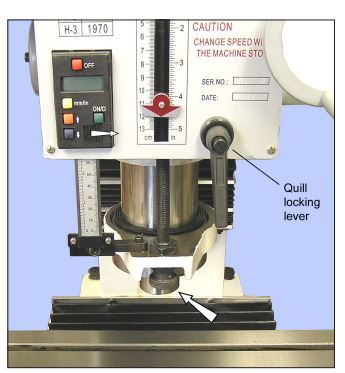

I was running at approximately .002" DOC, About 3/4 of the tool cutting, conventional milling, manual feed.

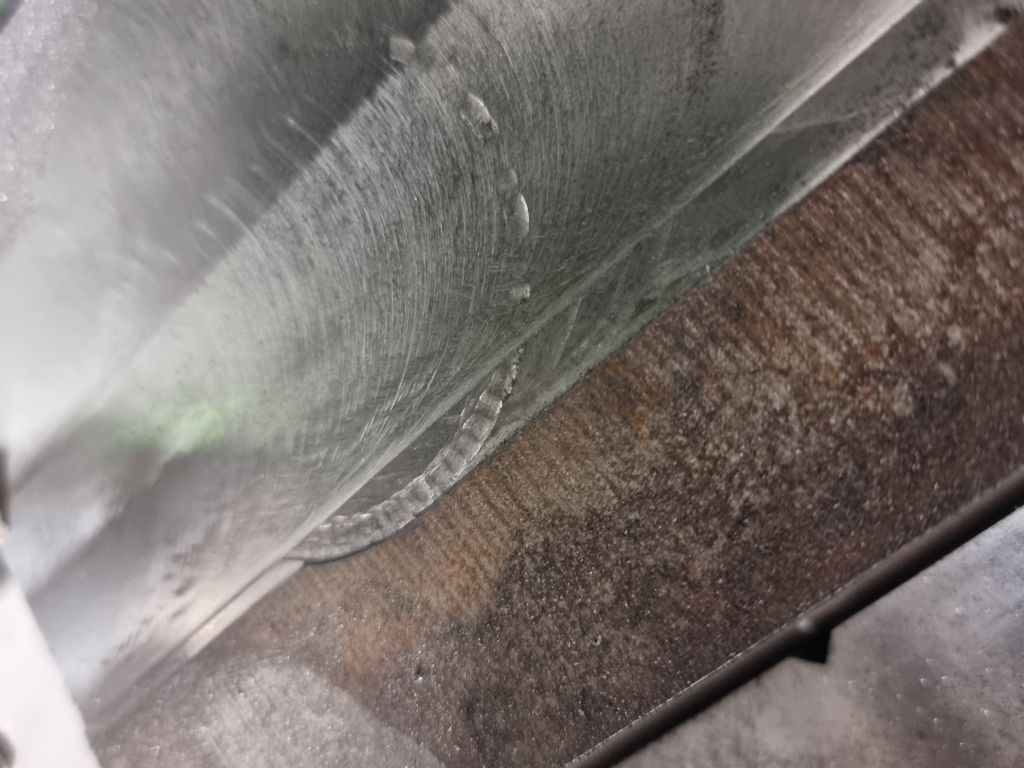

Part way through the cut, I started to get vibration and it just felt.. sketchy. I turned the machine off, and it appeared the cutter started to dig in to the material.

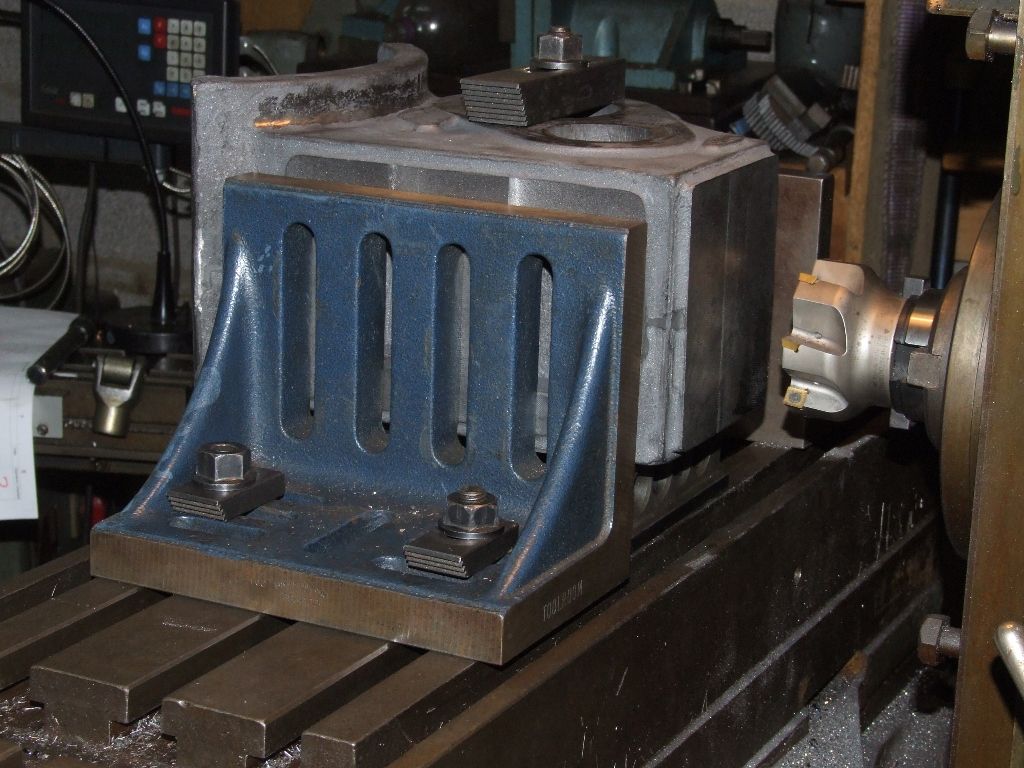

All unused ways were locked. The material was tight in the vice.

What I'm wondering is: (a) is this tool suitable for my machine (b) perhaps I should have roughed the surface out using an end mill and then finished with the face mill (although I'm skeptical this would help, the DOC was very small to begin with).

It's hard to describe, but running the cutter just felt sketchy. It felt like it was on a knife edge – like the slightest bit of interference would cause a problem and chatter and potentially cause the cutter to grab.

Other things to mention: I've checked spindle runout, all is good. Obviously the mill was screwed on tight, drawbar tightened appropriately, etc.

Ay suggestions to point me in the right direction would be appreciated.

Thanks

P.s. I've added some photos, one of which you can see where the tool started to dig in, and another where you can see how this big piece of cast iron is in the vice etc.

Edited By Jak2g on 06/04/2022 22:15:38

Edited By JasonB on 07/04/2022 06:58:23

Martin Connelly.

Martin Connelly.

![20220407_102049[1].jpg 20220407_102049[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/906399.jpg)

![20220407_102052[1].jpg 20220407_102052[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/906400.jpg)