Posted by Jouke van der Veen on 08/02/2022 19:50:39:

I understand that with your caliper check you can work wit an accuracy < 0.1mm for measuring gear tooth thickness, but not down to 0.01mm.

My calipers aren't that accurate but i find repeatable results within 0.02 mm. You can do the same measurement using a micrometer.

I make my gear cutters using a CNC lathe. Both sides of the gear cutter are cut using the same "parting style tool". This tool is a triangular insert tool at 0°. I prefer an insert tool because the nose radius gives a better finish. Also, insert tools are better suitable for cutting silver steel. You can also do this using an HSS parting tool or a L and R tool.

The tip of the turned cutter is mostly within 0.03 mm of target.

In the milling method you describe tooth foot radii are shaped with the appropriate end mill diameter.

I did not yet check if I can reproduce your method. For instance, I do not understand how you can make a M1 58 teeth gear cutter with a 20mm end mill. Is this a typing error?

No, this is not a typing error.

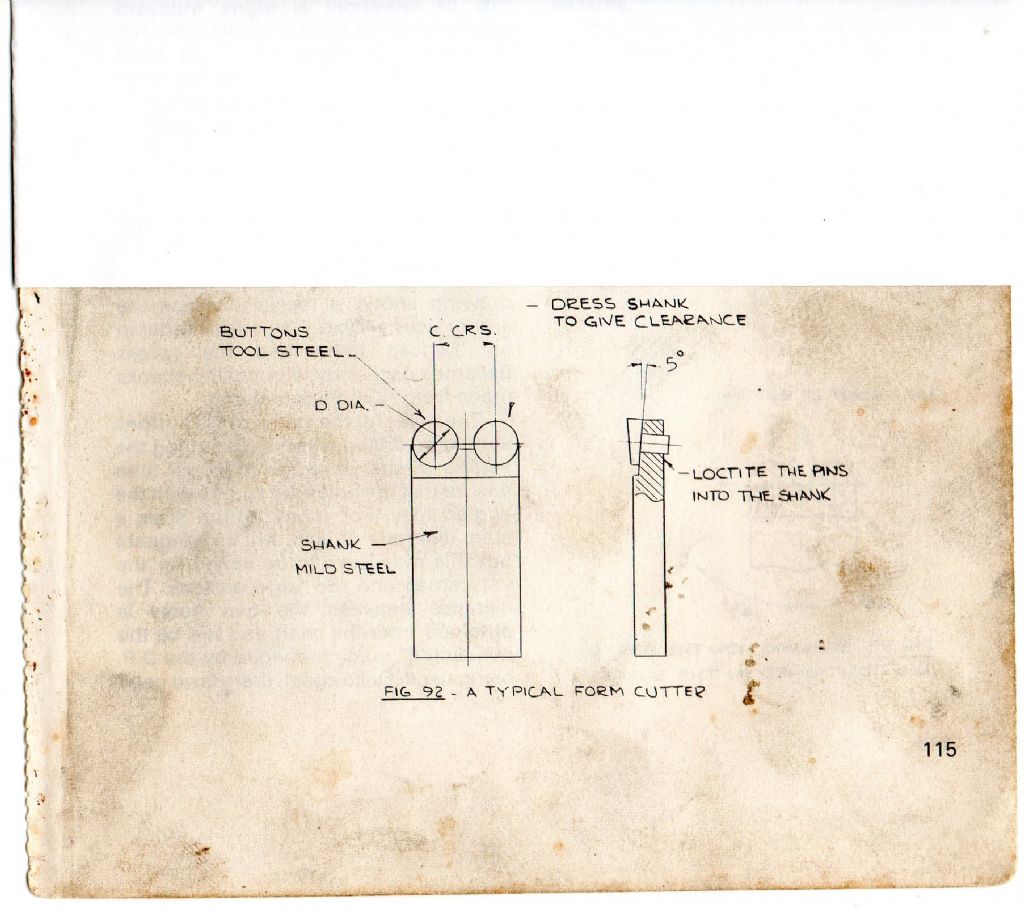

You would normally use a #7 involute cutter that can cut gears having 55 teeth or more. If you would make this gear cutter using the button method, you would need a 18.81 mm button to shape this gear cutter.

I do not have a 18.81 mm end mill (could use a cutter head). If I use a 16 mm end mill, I can make a 47 teeth or more gear cutter. If I use a 20 mm end mil, I can make a 59 or more teeth gear cutter.

in your following response you speak about gear tips of 1.1 and .82mm I expect these are for involute gearsand not cycloidal.

Yes, you are right, the numbers are for involute gears. I didn't realise that clock makers use cycloidal gears. I am going to read that chapter from Ivan Law (again).

In both cases, the making of the gears are based on the button method. So you to should be able to produce these gear cutters using an end mil. On the lathe I turn the gear cutters using a spacer. This will give an eccentric tool path and this will create clearance on the cutting edges.

On the mill I used a rotary table and placed the gear cutter blank eccentric.

I can make the gear cutters also on my small HBM300 lathe, size doesn't matter.

I have seen a YouTube video where they used a (tapered) drill for drilling holes in sheet metal. The tapered drill creates the clearance and it lets you choose "any size".

If the thickness of the tip is a problem, feed the button 2 mm deeper. Than you can measure the thickness of the tip easier. When all is done, turn the tip 2 mm shorter.

I am confident that you will be able to make gear cutters using the one button tool. So keep trying until you get it right.

Regards, Huub

Huub.