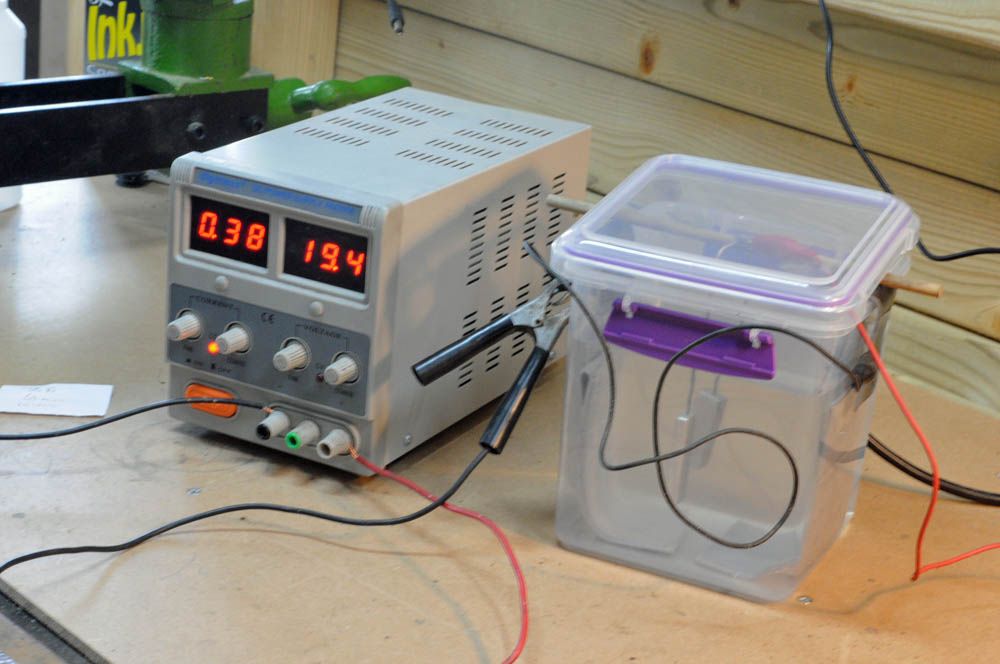

I've been having a first go at anodising. I've been intrigued by a few comments on the web about using Sodium Bisulphate as a substitute of Sulphuric Acid. My setup is a 30V 5A bench power supply and some lead cathodes in a plastic food container.

I used a commercial dye bought, like the Sodium Bisulphate, from ebay.

Results are as follows:

On the left are the first attempt in 25% Sodium Busulphate. A 720 rule calculator suggested 0.3A for the size of specimen. Very disappointing. I used some Ti wire to support the specimens and it seemed to be very difficult to maintain a current flow.

I have some legacy Sulphuric Acid which I have diluted down to the legal (in the UK) 15%. The middle specimens were anodised in this solution at 0.5A and I used Al suspension wire. Very happy with the results.

I then tried again with the Sodium Bisulpahte but with Al suspension wire. Again, it was tricky to get a really good contact with the specimen to achieve a current to flow. The maximum current I managed was 0.3A with the voltage turned up to the 30V max. The result was the specimen on the right, indistinguishable from the middle specimen.

I'm afraid the "experiment" was not very well designed – too many variables changed at once but it does seem that, given the right conditions, Sodium Bisulphate does work for anodising. 15% Sulphuric Acid is also perfectly good and would appear to be a little easier to use but not so nice to handle and store. I also don't know where one could buy even the legal 15% solution.

Anyway, I hope this helps anybody wanting to do some home anodising. Look out for model engines with purple heads and spinners.

Cheers,

Rod

Edited By Roderick Jenkins on 04/05/2019 16:08:48

Neil Wyatt.

Neil Wyatt.