Torn threads and multiple starts are probably caused by different issues. First we need to sort out the multiple starts. More information is needed:

What is the OD and pitch of the metric thread to be cut?

What lathe is being used, and is it imperial or metric?

Can it cut the required pitch?

If it can, be aware that higher spec lathes have multiple gears on the thread dial indicator – you need to use the correct gear for the required pitch

Note to SoD – hooray for imperial and tpi

For the torn threads, again more information is needed:

Is the tool HSS or carbide threading insert?

If an insert where did it come from? Hint: bang good is the wrong answer.

What is the material, and where did it come from, ie, known specification or gawdonlynose scrap?

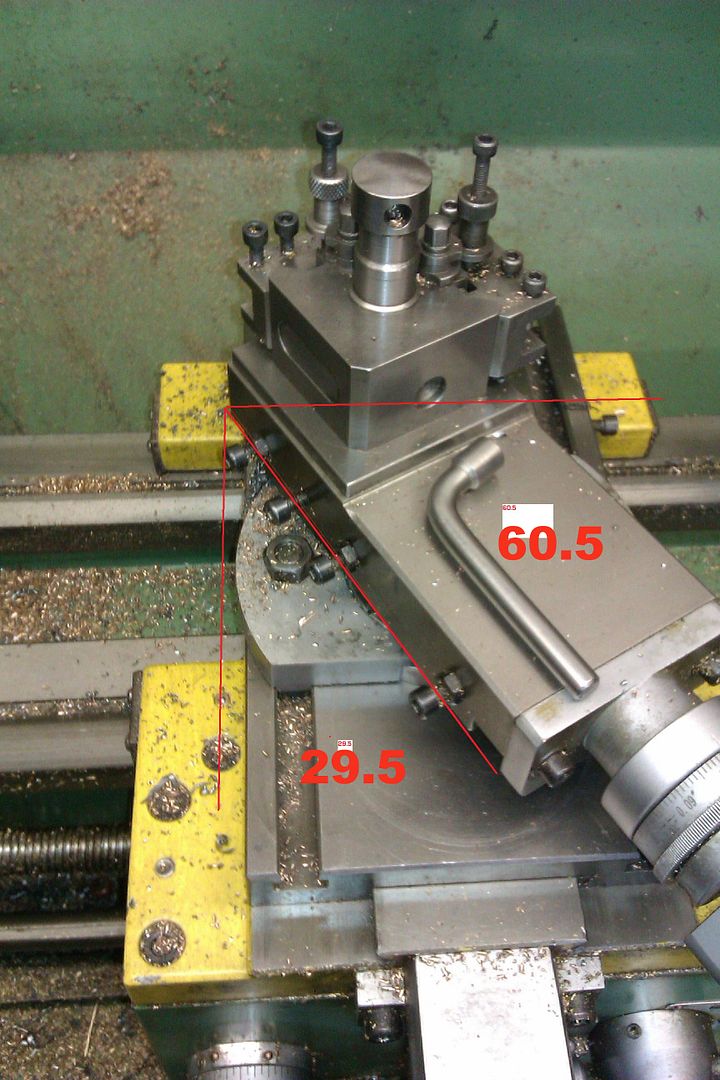

A picture of the setup would be helpful.

Andrew

Hopper.