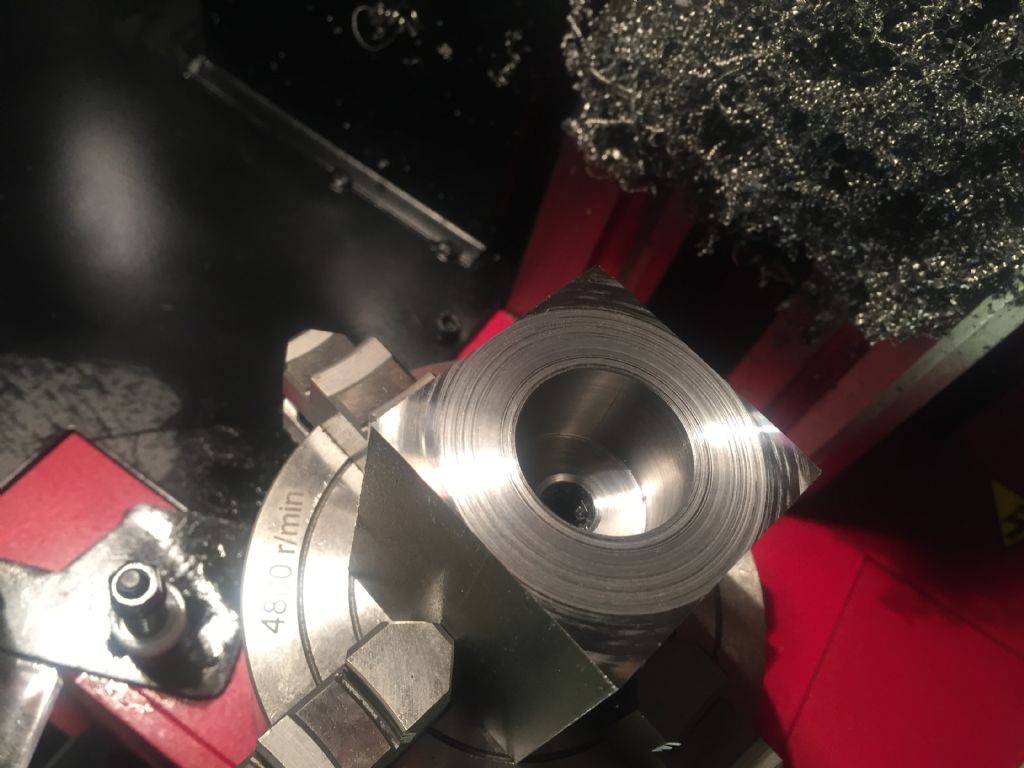

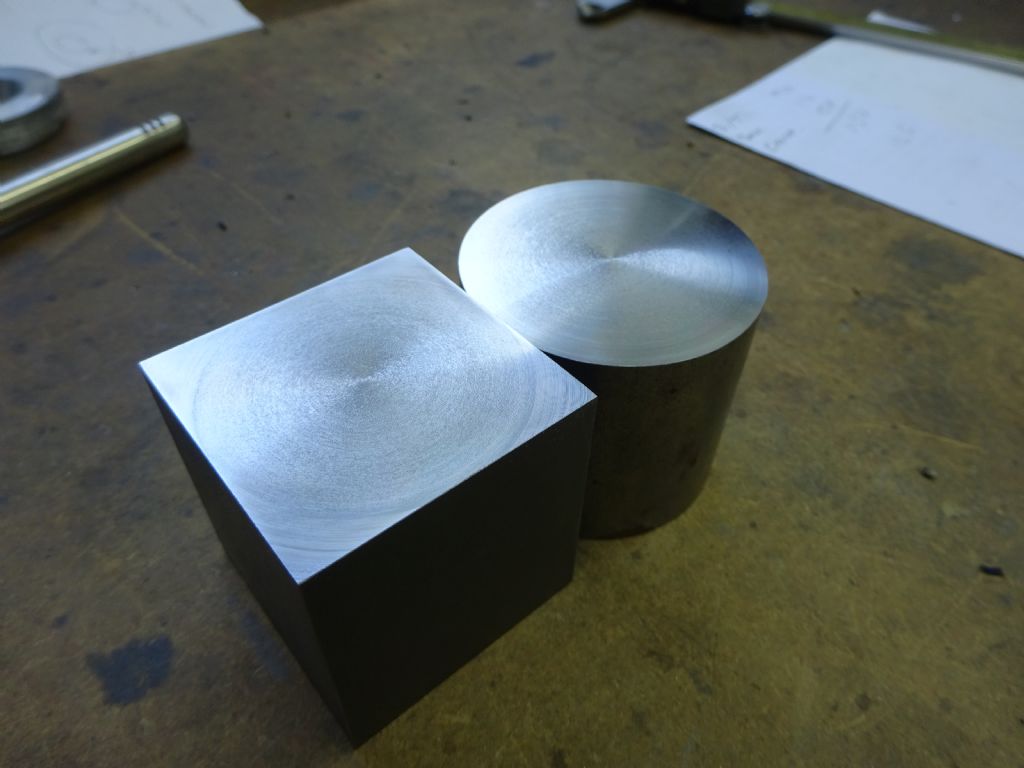

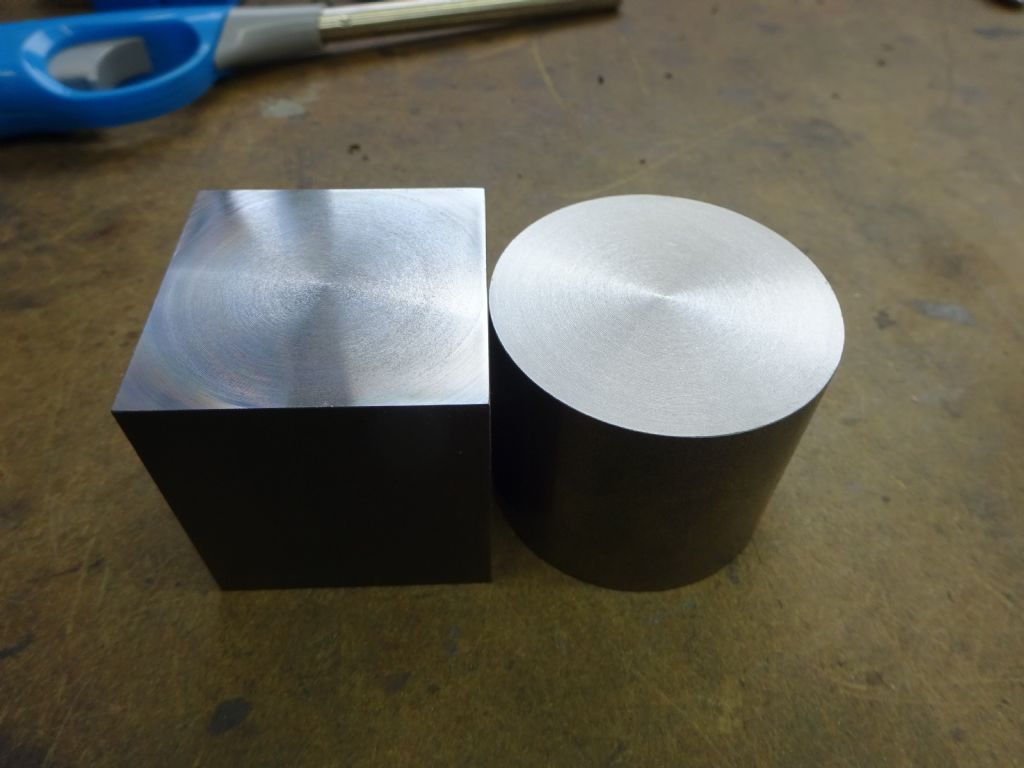

I took a few cuts off the end of a bit of 44mm sq EN1A bar starting with cautious cuts which is what Nige said he was taking and worked upto some heavier ones to see how that affected the finish. Tip was Kennametal CCMT with 0.2mm tip radius, my weapons of choice for shifting metal are a pair of holders that make use of the obtuse corners of the CCMT inserts that don't get used in the usual SCLCR/L holders. Cut dry.

0.020" DOC, 0.0015" per rev, 800 rpm. Bit rough all over with the corners looking slightly better.

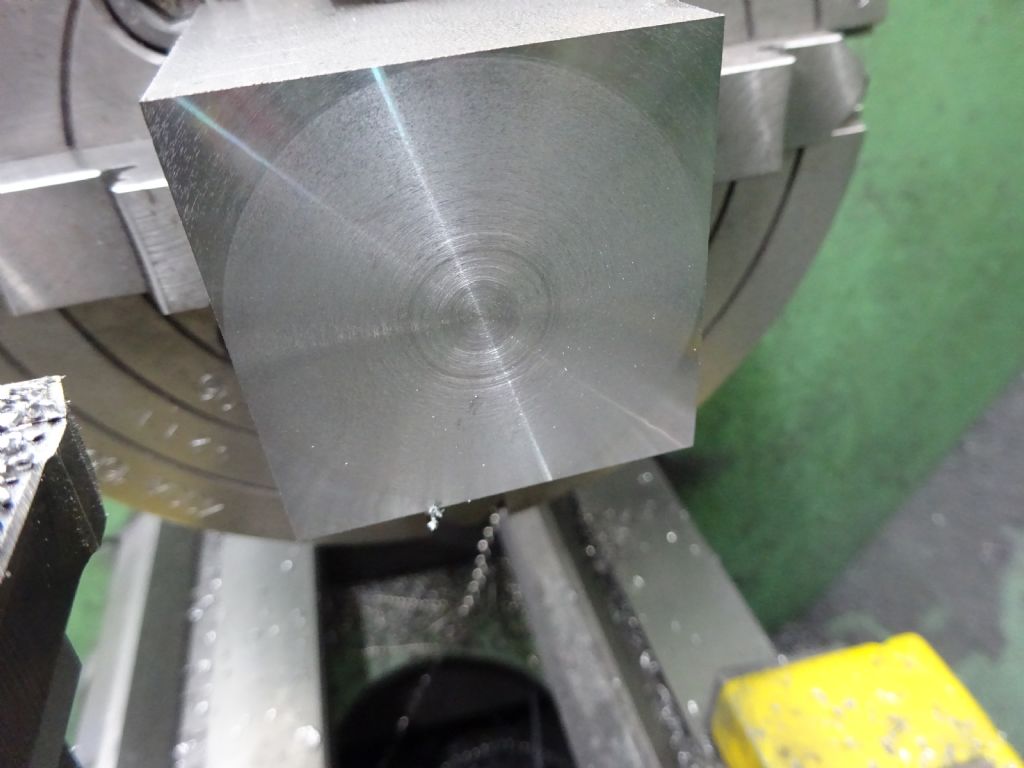

Same cuts but at 1000rpm, slight improvement and showing the brighter corners like Nige was getting.

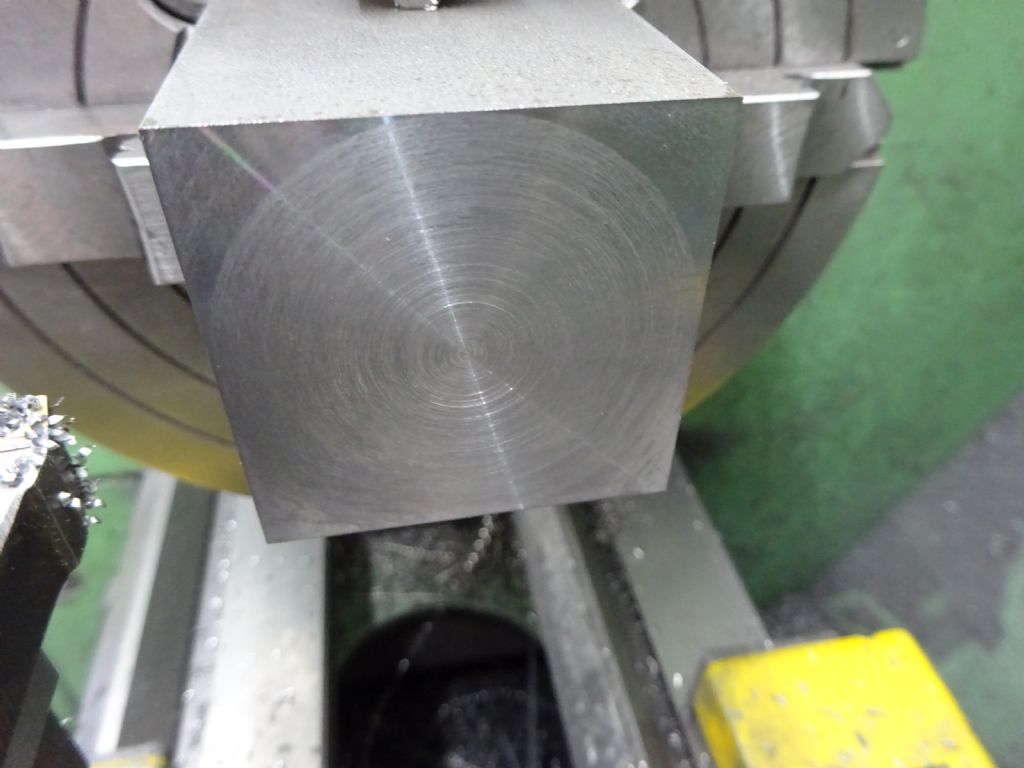

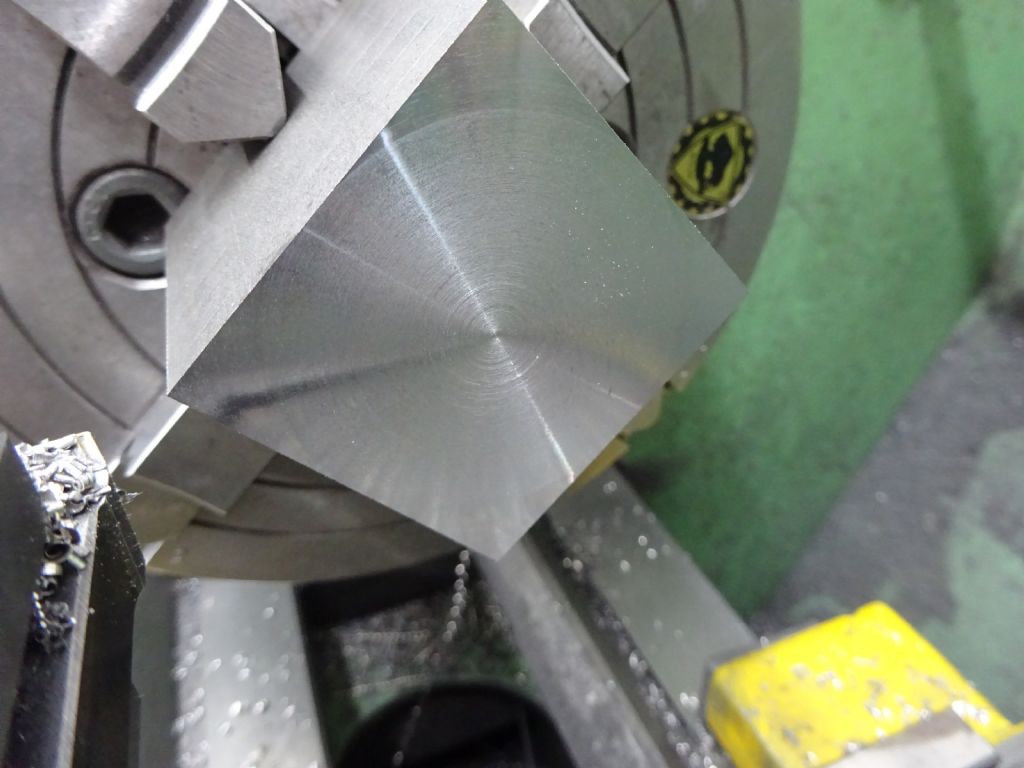

0.030" DOC, 0.0015" per rev, 1000rpm, getting better but still gloss/matt

0.040" DOC, 0.0015" per rev, 1000rpm

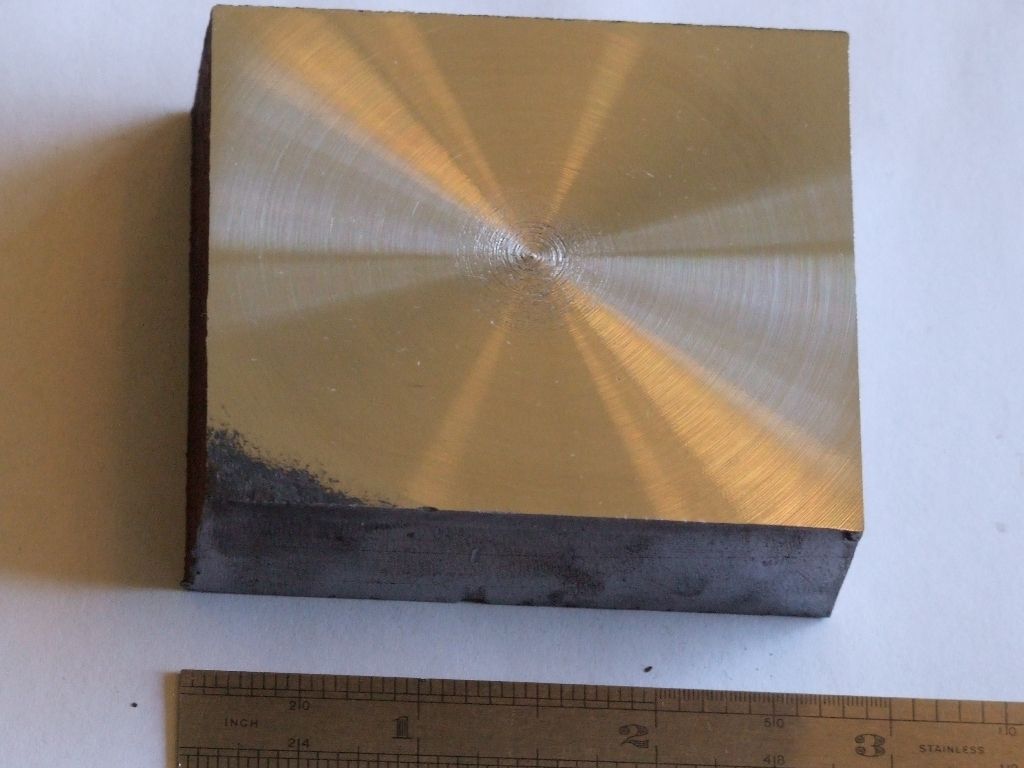

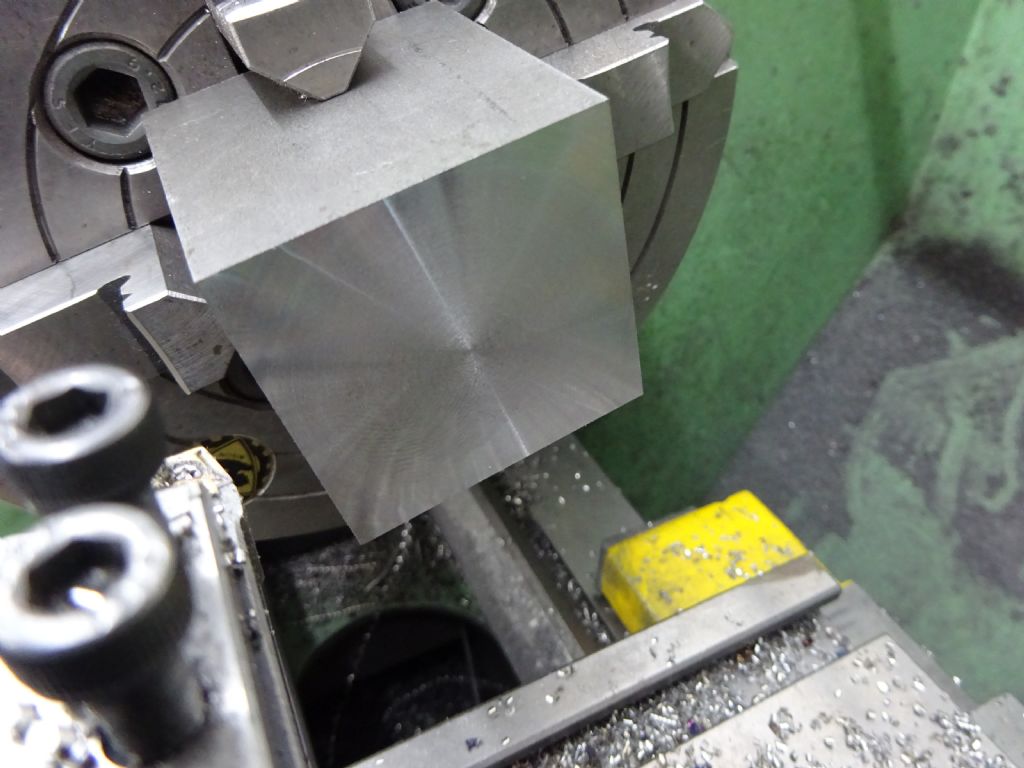

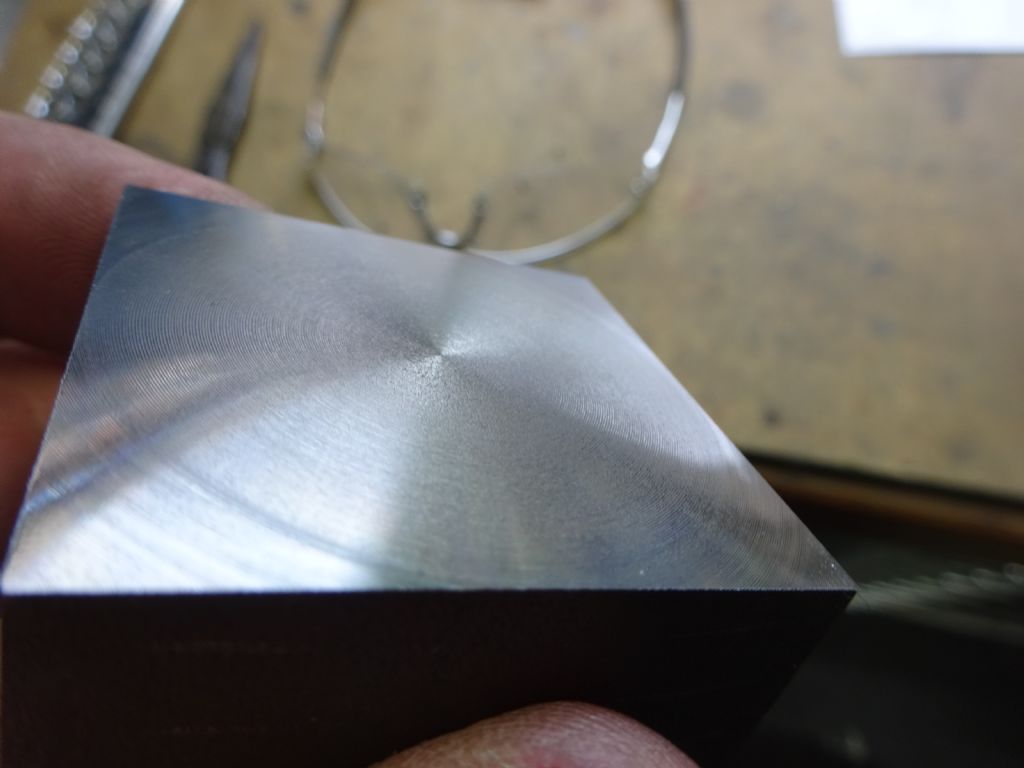

0.040" DOC, 0.003" per rev, 1000rpm almost even finish right across

0.040" DOC, approx 0.005" per rev as this was hand feed as I would have needed to alter change gears, 1000rpm that's about it

And from another angle, picking up a little in the middle but at least my tool looks to have been on ctr height

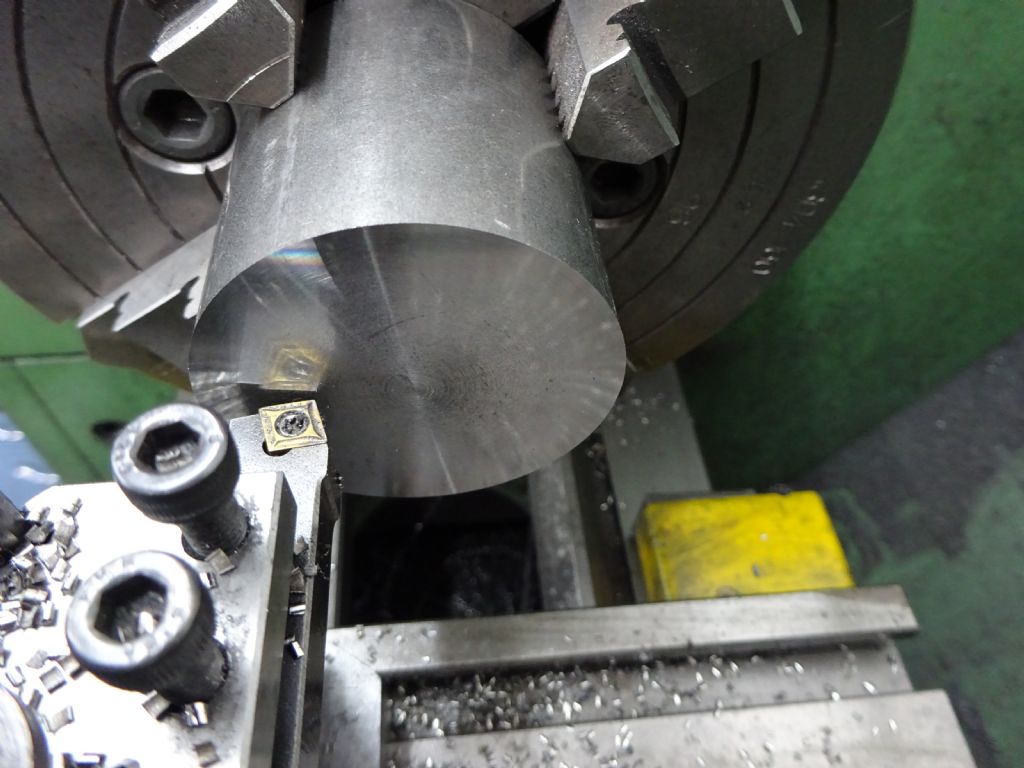

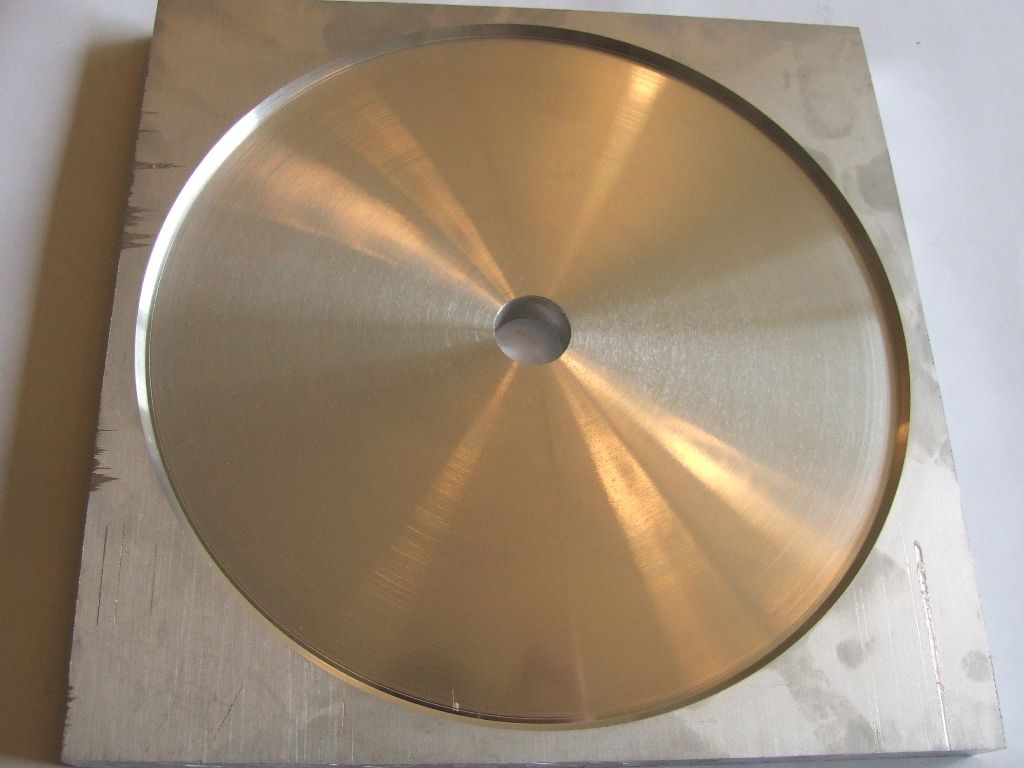

Changed to a bit of 50mm round EN1A and took a 0.050" DOC at the same sort of 5 thou per rev. You can see the reflection of the tool is better towards the outer edge where surface speed was higher but still not bad and you can't feel the difference if aperance though I don't have surface comparitors just a dirty finger.

I think Nige has one of ARCs SCLCR holder so did a 0.040" cut with one of those and got a similar finish to the other holders.

Finally did a 0.005" DOC, 0.005" per rev, 1000rpm cut with a CCGT 0.02 tip rad (on the right), no tearing but not the reflective surface that the other cut gave (on the left).

So it looks like feed rate may be the main factor to avoid the shiny corners and matt middle, Andrews cut was around the same sort of feeds as I was getting the even finish. The main problem with this on the smaller vari speed machines if that you can't take these heavy fast cuts as the diameter gets much bigger without starting to stall them and as Neil mentioned the tool can start ot move a bit quickly which can be off putting for a beginner particularly when working to a shoulder.

Edited By JasonB on 09/06/2018 08:26:42

Ian S C.