It's nothing to do with work hardening; I doubt the steel is anything other than low carbon. It's all to do with spotting to start with. In my experience it's a waste of time when using "small" drills. Preumably you're moving the work between machines between spotting and drilling? How are you lining up on the spot drilled location?

If I was drilling said holes I'd do it like this:

1. Use a 4-facet drill – I use Dormer

2. Just drill straight off, don't try spotting or centre punching first

3. Use a squirt of WD40 or very thin oil to lubricate

4. For this size drill I'd be running my Bridgeport at about 2000rpm – could be faster but it gets noisy!

5. Let the drill cut and be positive with the feed – at 2000rpm, two flutes and 1.5thou per rev per edge that's 6 inches a minute

6. For 3mm depth you probably don't need to peck, but one might be used if one is on the cautious side

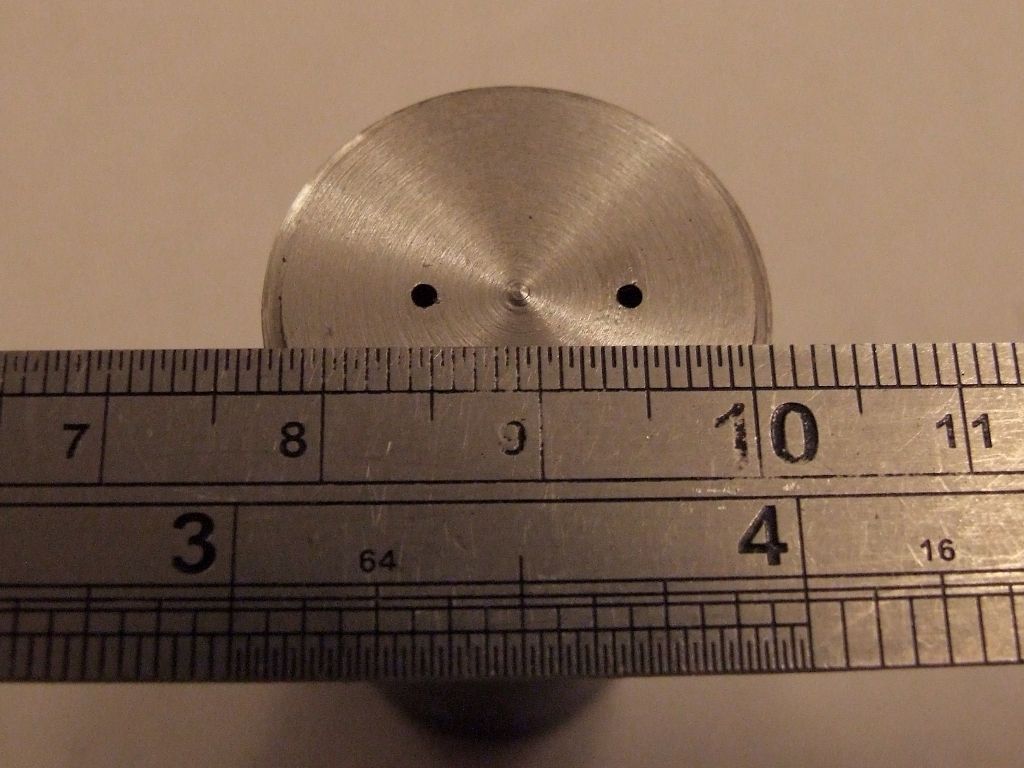

If yoiu're careful when starting the drill you can get away with a 2-facet drill. Shown here are 1.2mm holes drilled 8mm deep in tungsten alloy on the Bridgeport with no spotting (tungsten carbide drill):

Andrew

Anonymous.