Chris,

I sometimes do it the hard way – i.e. cut from solid!

It all depends on what kit you have. If you have a rotary table and pillar drill/ mill it becomes relatively easy – oh, and have access to CAD so you can plan where all the holes have to go!

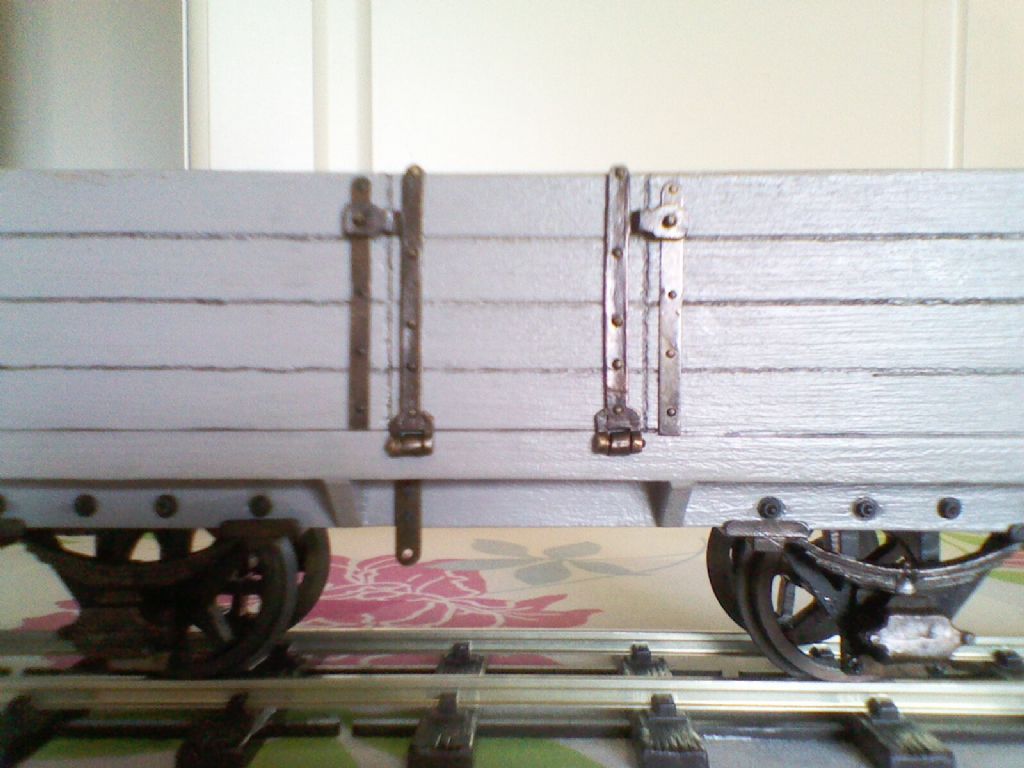

I make railway models in 16mm/foot scale and wanted to make some Irish 3 foot gauge wagons. I couldn't get suitable sized spoked wheels (finished tread size 32mm dia), so I made my own.

I first drew the wheels out in Turbocad and then messed around with hole diameters and positions to create something near to what was needed. A key thing was to position all holes on whole degrees around the wheel (just to keep it simple when whizzing the rotary table round). Having drilled the holes, I put a mill in the drill chuck (naughty me – but if you are careful it is Ok) and removed the bulk of the unwanted material – again, I used Turbocad to work out where to place the mill and only plunged a single hole (rather than attempting to mill a shape). See the picture below and it should make sense. Each triangle is made up of three holes (where spokes meet the rim or hub) and a central, larger hole where I plunged the milling cutter.

Having got my roughed out spokes (on the left above) I then filed them to shape (the one on the right). It took just over an hour per wheel and I did it whilst on holiday, away from my machine tools (I do have a vice in my holiday home). A not very good picture of the result is below.

It is a lot of work, but satisfying. Just for a laugh I did a split spoke wheel as well – the third picture in my Wheels album.

As Jason B pointed out, if the loco has outside frames, you aren't going to see much of the spokes, so you are more likely to get away with plain spokes (rather than oval)

Hope this helps

Regards Tom

Chris Hammond.