Hi Bazyle ,

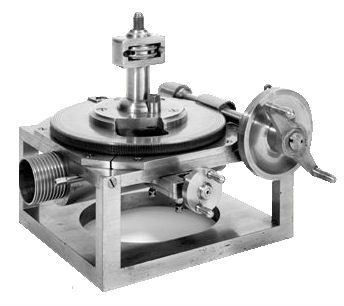

There was no consistently accurate method of setting out large (more than a few inches) linear distances in an ordinary production shop before about 1920 . Around this time the high accuracy jig borer started to get into general use . One of the first companies to manufacture these was Societe Genevoise .

Jig borers initially used two methods for high accuracy work :

(1) End on end stacks of slip gauges set between precision stops . Very accurate but tedious since a new stack had to be assembled and set for every move .

Some more inspired machinists no doubt made themselves a selection of length bars equivalent to slip gauge stacks needed for more commonly used distances .

(2) A precision screw thread and basically lead screw dials . Very accurate screw threads were available long before the 1920's but don't seem to have been applied to anything except ordinary lathes much earlier .

As time moved on other methods appeared including long Vernier scales and precision glass scales both viewed through a built in light and magnifier system .

Nothing much happened then until Heidenhein introduced an early version of electronic DRO in the early 1950's .

The above applies to ordinary industrial use . For scientific work optical setting out methods were in use very early on and these were developed progressively into modern interferometric and laser systems .

The clock making industries had mini versions of jig borers a good bit earlier than general industry . These were mostly screw based and their primary use was 'spotting' the centres for clock plates .

Notes :

(1) When designing accurate machines there is no way of 'beating the system' . Somewhere in the machine there has to be a fundamental length reference . This can be a screw , scale , assemblage of slips , a laser system or one of many other things . However once a reference system has been decided on there is no way of making it 'more' accurate by adding complexity .

(2) Very few machines have ever used a rack as the fundamental reference . Probably because it is much more difficult to make an accurate long rack than an accurate long screw .

There's a lot more to this .

Regards ,

Michael Williams .

Edited By MICHAEL WILLIAMS on 31/03/2012 15:35:06

Anonymous.