Michael – you are quite right.

But my point is that 99% of the world doesn’t part off at the rear, they part off at the front – and very successfully.

Yes many people do suggest going to the rear as it were. Good luck to them, but it isn’t the answer, because you can get jam ups at the back with this wonder geometry they all use. (I know from personal and very painful experience)

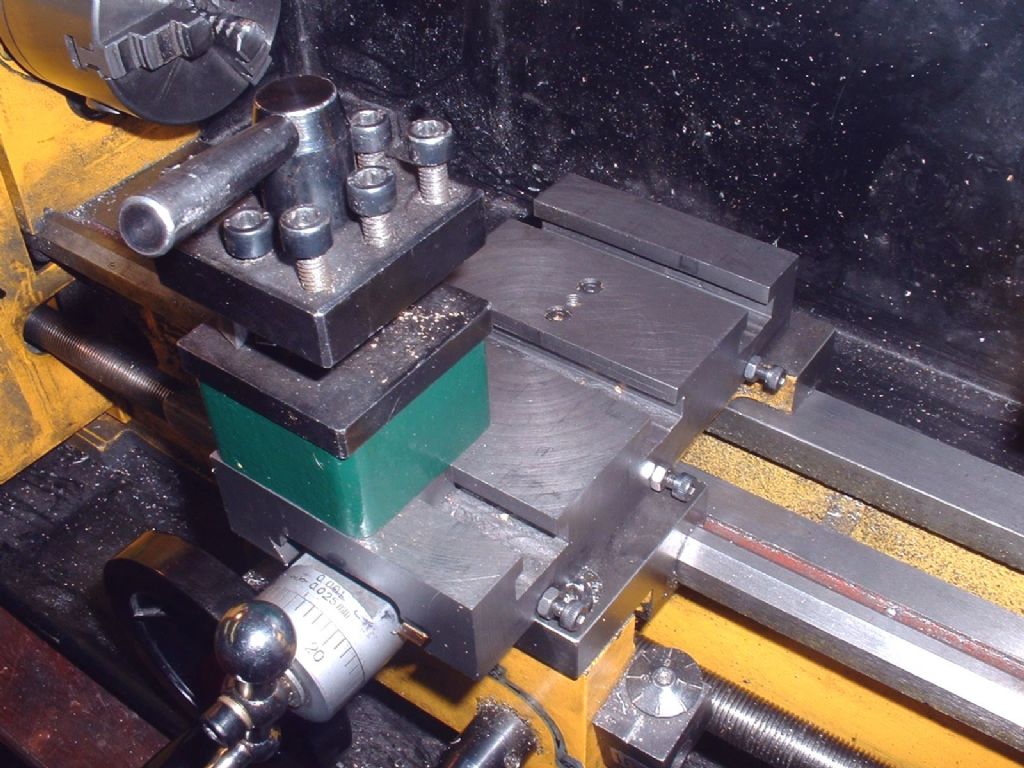

The answer is not to try to emulate this miracle (PITA actually because you end up all cramped up on a small cross slide), but to get it right at the front. If, as most people do (myself included at one stage) go for the steep back rake recomended by some authors (often from the days when lathes had much less power available) or use no coolant, or don’t take care to get tools square and at the right height so that if they dig in they tend to dig deeper rather than shallower, then you are getting down on your knees and begging for trouble, and one shouldn’t be surprised if it arrives in full measure.

(for instance – no coolant? OK apply a 90thou cut (2mm) you are doing a fair bit of work. The tool heats up – expands – the work heats up locally – expands. No wonder it jams, and we haven’t talked about rake angles pulling the tool into the work unrestrained because of backlash in the feedcrew nut (front or back). So it HAS to be about tool shape and position – not whether its at front or back.

And again, I speak from experience because I had constant jam ups and dreaded parting off. Then I thought about it, realised that the back toolpost was part of the symptom not the cure. I ditched my back toolpost, sorted out the angles,and nowadays I wouldn’t dream of such silly malarkey.

Normally I use on the Myford a narrow 2mm blade, but I have plenty of 3mm blades which have all been reground for special tasks like chamfering or handed parting, so they are cutting over a lot more than the nominal 3mm, and they work fine.(but they used to freak me out so easily would they jam) .

I truly do not understand why anyone would want to feed forces into a machine in a way that it was, very plainly, never designed to accomodate. Thats just half witted. Its about as sensible as building a suspension bridge to take loads in tension and then asking it to resist an upward push in compression

Its just not made to do it, and somehow that’s better?

Sub Mandrel.