This is a bit of a catch up on stuff that's been going on for the last couple of weeks.

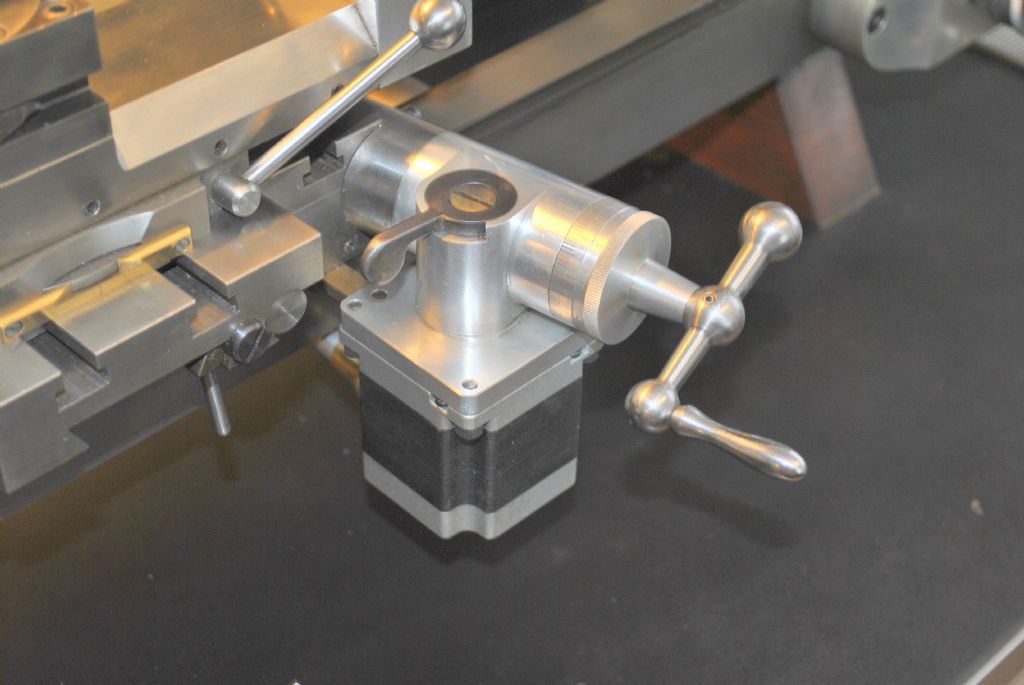

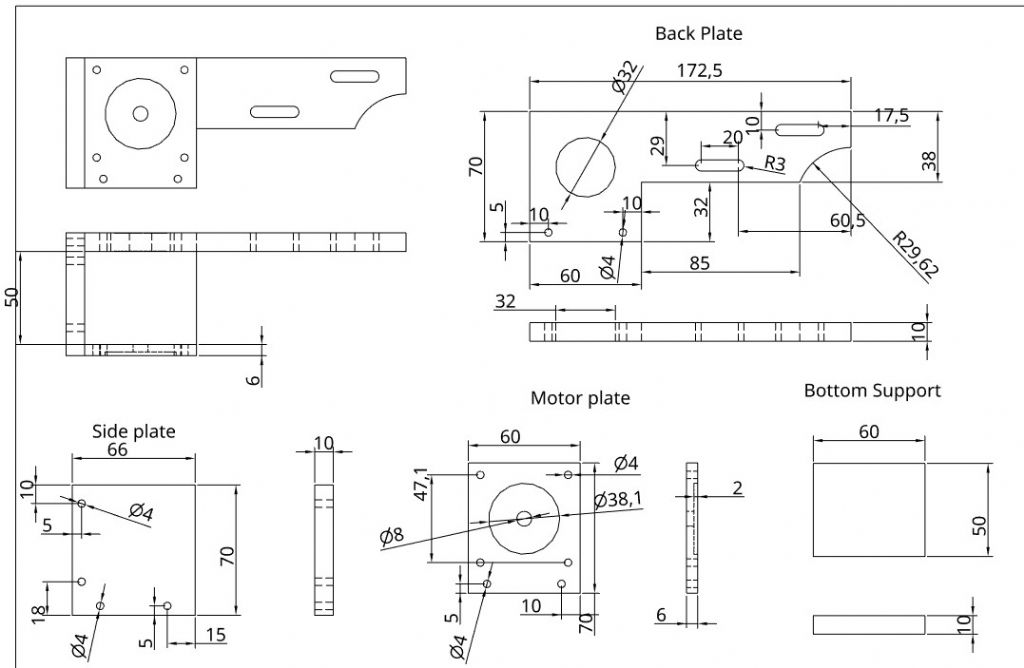

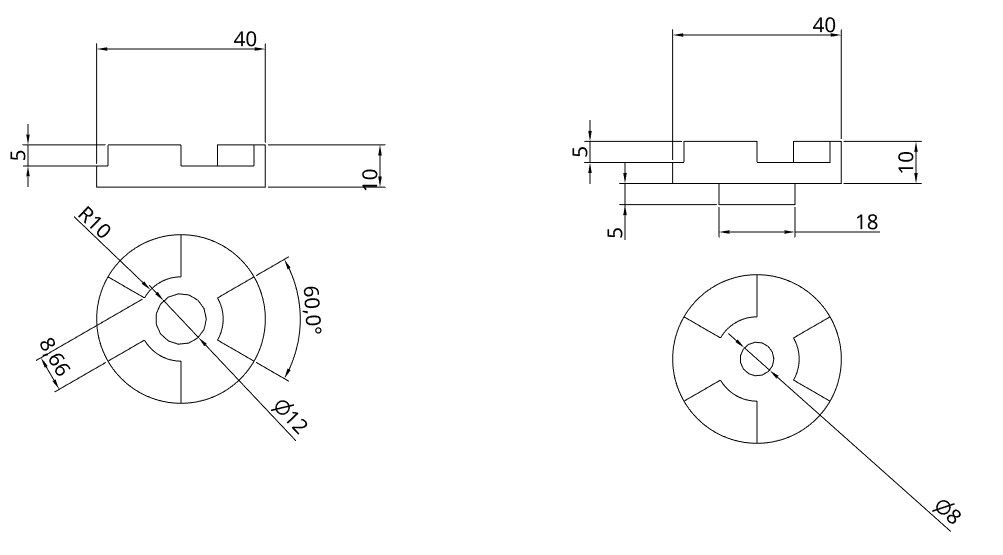

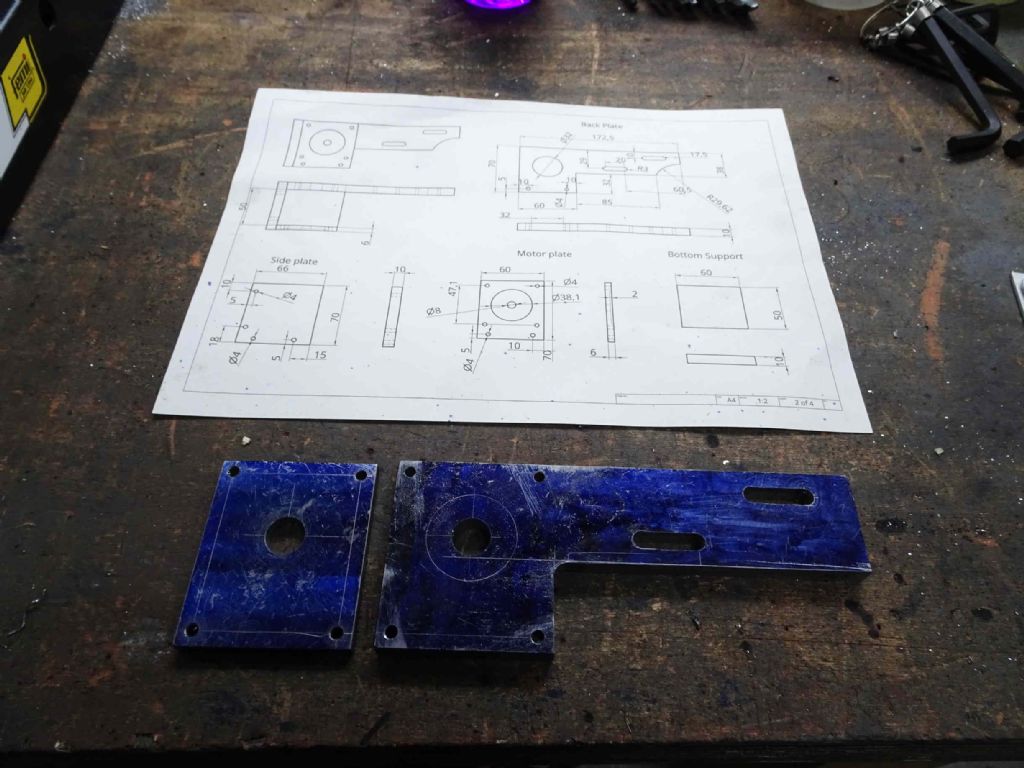

Following making of a Spindle lock for the mill, I cut the 4mm keyway for the 12mm shaft of the leadscrew in one pulley.

And a 3mm one in in the steel dog clutch half.

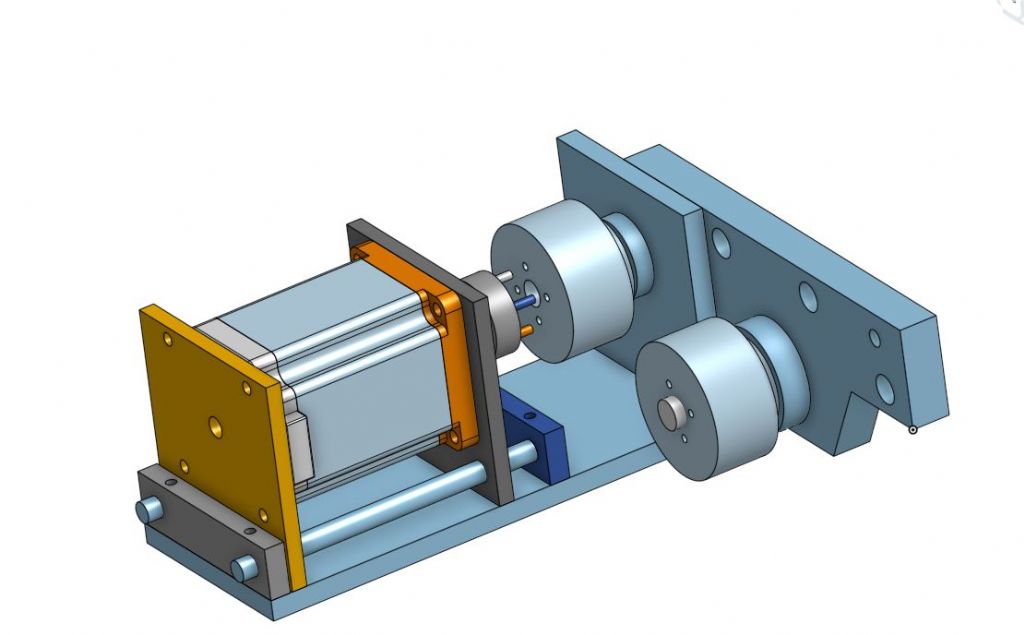

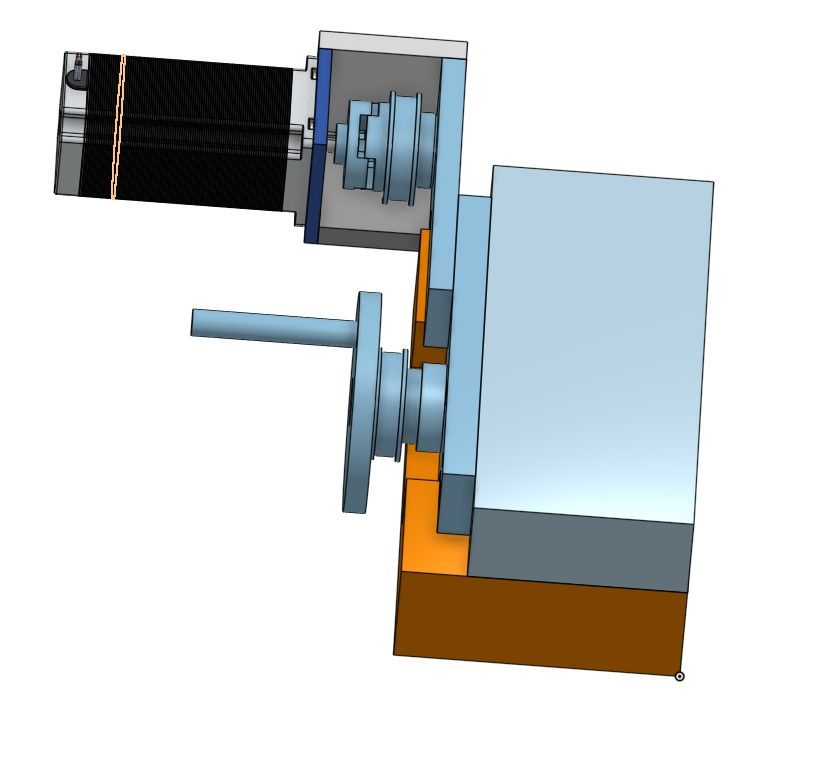

I thought I was doing well, but then I put it all together and found that the bracket is miss-sized (or the size I used for the pulley in the design was wrong) which meant it wouldn't fit. A bit annoyed by that.

After a few minutes expressive language, I realised that I could remove the bottom plate and replace it with two bars, one at each end where the bolt holes are. I believe I'managed reasonable precision (within a thou) of the length, so it may even be better.

It looks like that works (sadly no photo, but I'll take one when all the bits are together). The dog clutch parts engage with the various turning bits mounted by hand.

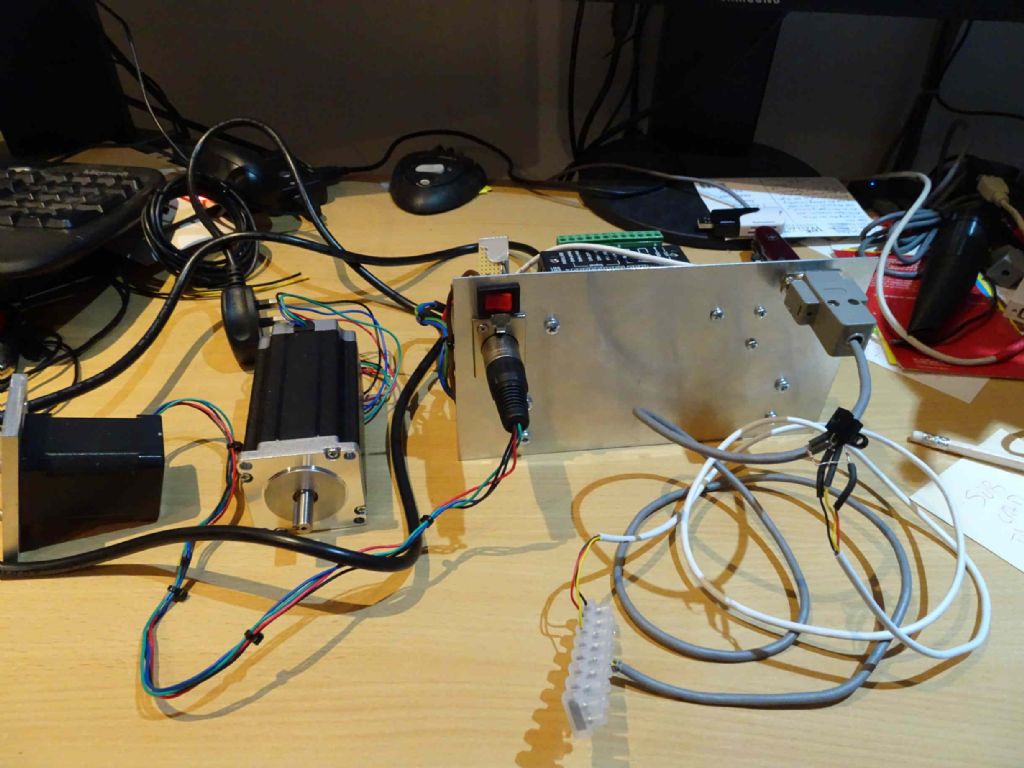

With that, I Loctited (638) the bearing into it's housing and left it to dry. Next is to loctite the shaft into the bearing and make sure everything moves freely. This is the bit which scares me the most as the tolerances are pretty tight.

Whilst waiting for the loctite to set, I started on the replacement handwheel which will get bolted to the X axis pulley.

I have a piece of 4 inch aluminium bar sourced from some show somewhere as a, 'That will be useful someday'. Well it will be, but I hadn't considered how I would cut it if it was wider than needed.

In the end I drilled and tapped the hole which the handle will go in, bolted it to an angle plate and clamped that in the jaws of the bandsaw vice. This lets just enough poke out.

Whilst this makes the job possible (and lets start by saying that cutting it by hand isn't work considering), it's going VERY slowly. I've got about a quarter of the way through in about 15 minutes.

I expect this would go better with a blade with coarser teeth (as it says on the machine), but I only have the one. Hmm. It might actually be worth investing in a coarser blade. The time it would take to swap the blade would hopefully beat the time saved in the cut.

I'm also thinking about automating the thing. Very brutal engineering. Basically just hang a weight on the end of the saw! I've already got a clip to keep the trigger down for when using the saw table.

Hopefully, next time I post, the mechanics will be done….

Iain

Iain Downs.