non-circular boring.. Literally – it is boring!

non-circular boring.. Literally – it is boring!

- This topic has 27 replies, 8 voices, and was last updated 18 May 2020 at 18:10 by

sam sokolik.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

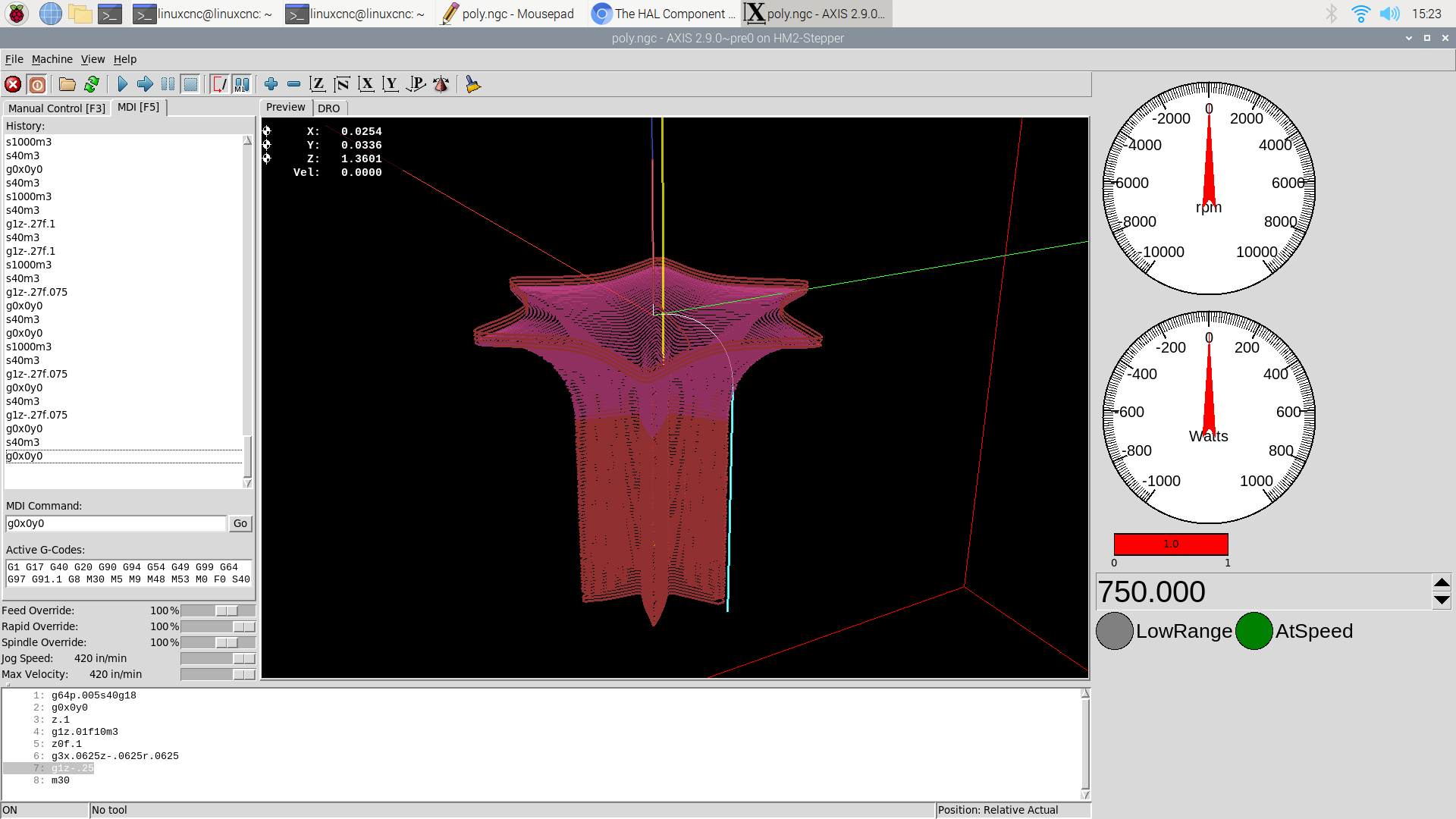

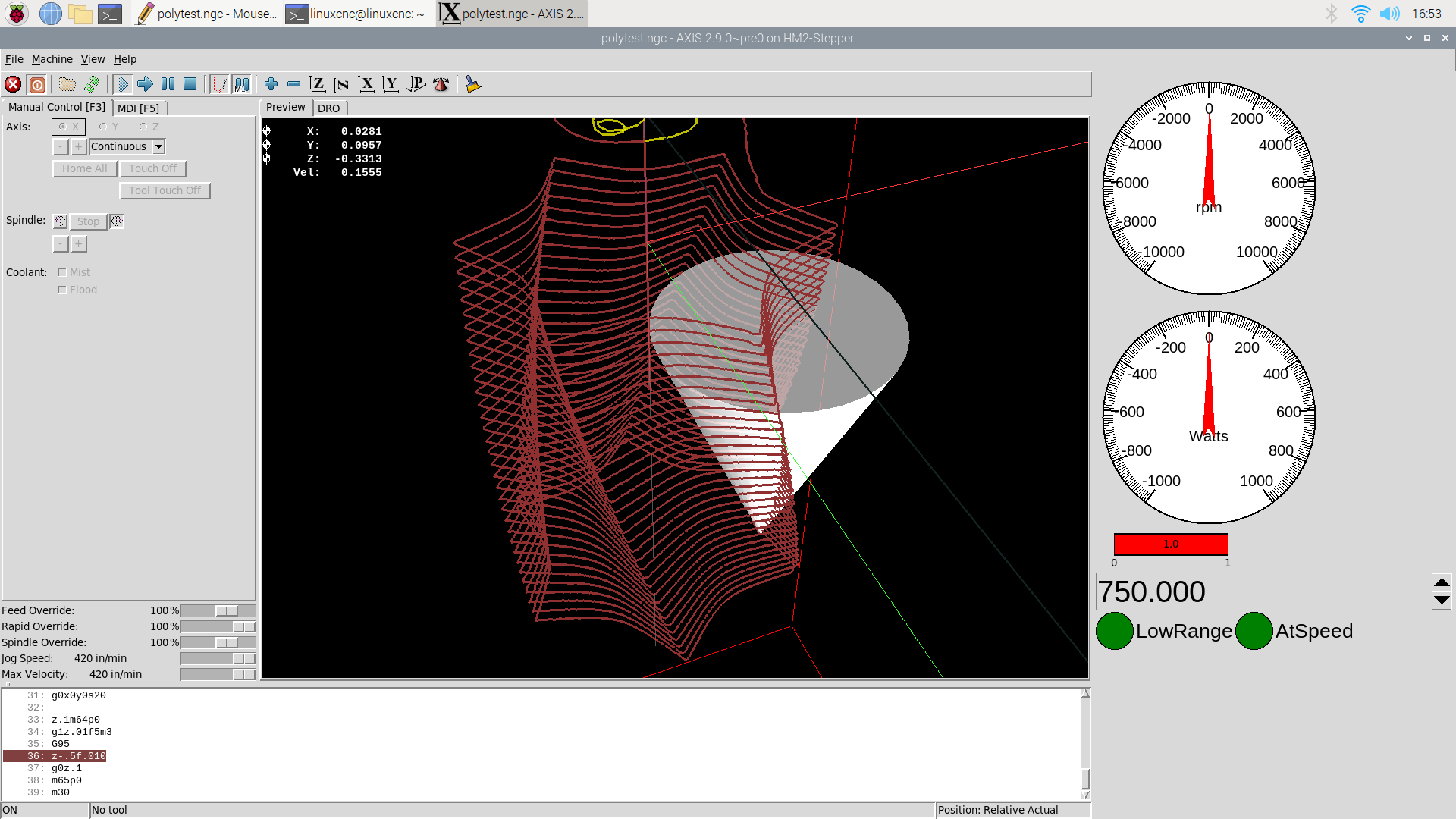

(the vertical lines are the encoder resolution…)

(the vertical lines are the encoder resolution…)