Barrie;

I read your comment about the Wabeco and handles for manual movement.

1) Look for "MPG"s – these things allow you to move the axes with a knob on the MPG, much like you'd do with a manual mill, and you have a built-in DRO as well. And, one can set the speed of the movement, so you have fine movement and the ability to get the table to move quite a lot without lots of cranking of the handle.

2) Your software should also allow you to manually move the machine table. With a mouse.

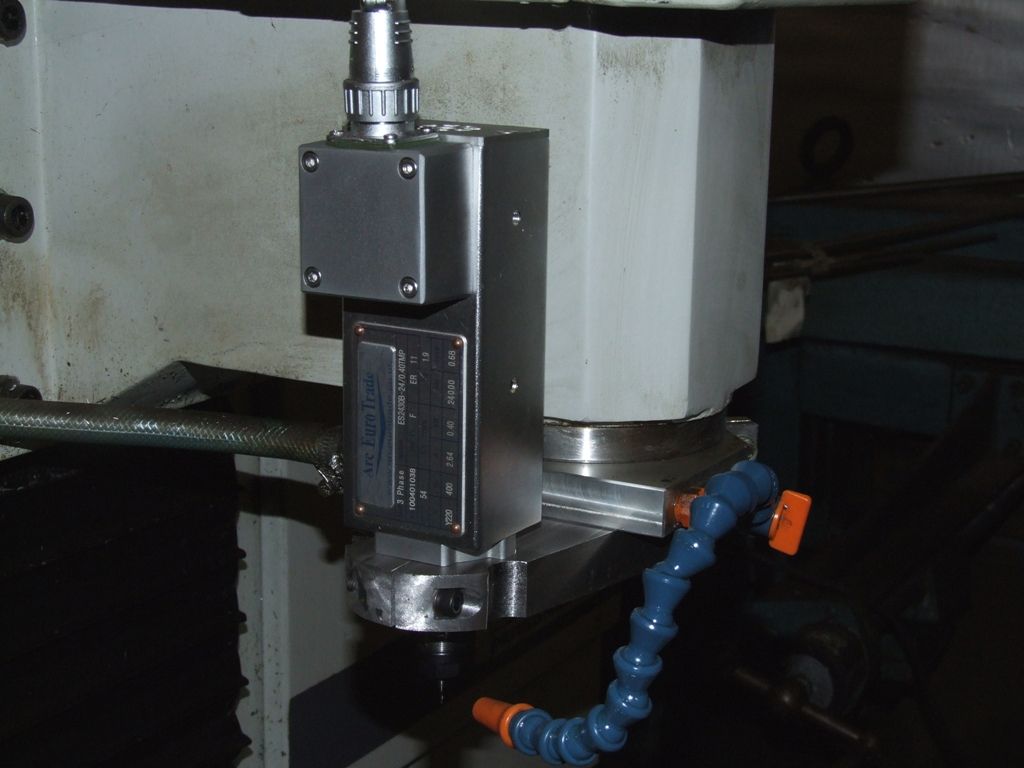

3) I have 2 CNC mills, one has a spindle quill on it. I don't have a pillar drill, and, while I do have another largish mill with a quill, I tend to just use this CNC one in manual mode. I flip on the power – the computer boots up, and it's ready to use. The MPG gives me axis movement, spindle speed setting, and a DRO.

4) LinuxCNC (and, likely PathPilot, which is LinuxCNC with a different GUI) has built-in the ability to engrave from image files, like JPGs.

5) My CNC mills do not have any keyboards in the common "computer" sense. I do have track balls and do have numeric keypads connected, but these last ones are rarely used, as the computer screen allows you to select numbers. If I had touch screens, I'd not even bother with the trackballs.

All in all, my CNC mills get used more than any other thing in my workshop, I'd expect.

This is all fun stuff.

Edited By John Alexander Stewart on 28/12/2018 22:19:57

Another JohnS.