So after that thread a while ago about aliexpress spindles it seemed they wouldn't work and that I could probably do better myself for the same money.

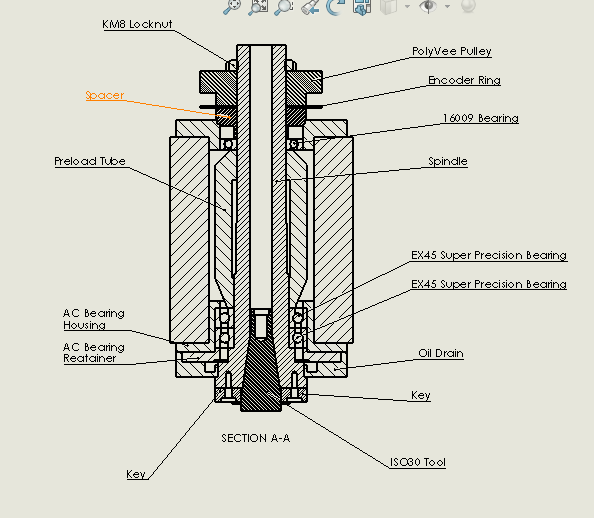

Here is my initial sketch model of the spindle. The hiccup of today is trying to keep the spindle lubricated, seems much simpler for horizontal spindles than vertical ones. Spinning in the region of 10,000 RPM I need to have oil lubrication of some sort.

My current plan is to have the oil injected through a port at the top above the 16009 bearings and have it rain through the bearing and down to the EX35 bearings then collect at the bottom in the "drain" flange. Not shown would be a sideways pipe to suck the oil back to a tank.

Would this lay out work adequately?

Somewhere on the SKF website that I have now lost I worked out I needed about 1 liter per minute or a bit below that. Aside from knowing if the general premise looks ok I also can't find a pump for that flow. Peristaltic pumps are undersized and the rest are over sized and I dont know how well they would work under capacity. The other worry is how well £20 chinese pump will last. Last issue is that this is all flying about on a fixed gantry mill so either has to be small enough to mount on the head or powerful enough to give lubrication from a way aways (which also adds some piping issues).

If no one knows a good pump could they refer me to a book or guide to designing them? Internally debating making a piston pump for high pressure oil jet lubrication.

HOWARDT.