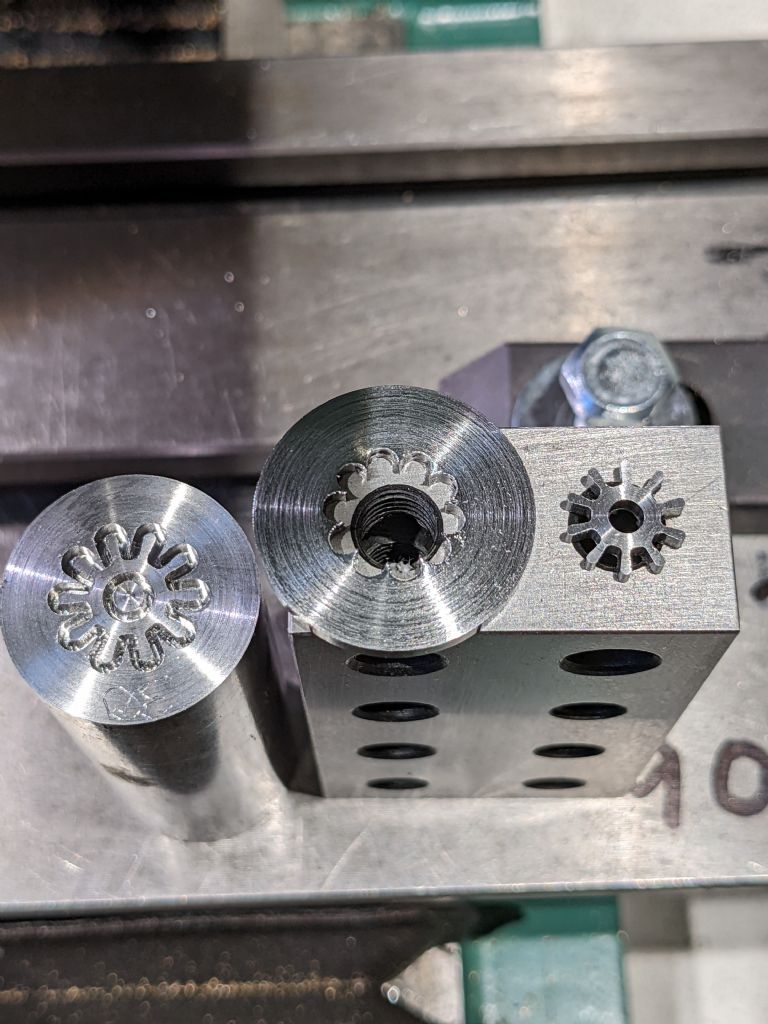

I'm doing some relatively fine work (0.25mm holes for example) and so I've built a high speed milling spindle for my mill. By high speed, I mean up to 19,000 rpm. It has an ER11 collet.

So far I've tried to use two types of (carbide) end mills. There's one sort readily available on Amazon which has a 1/8th barrel and quite a long cutting part (so perhaps 1mmx 20mm or so). It's not always clear if these are meant to mill metal, but some seem to be.

The other is a more clearly metal oriented end mill from APT (who very kindly suggest speeds and feeds on their site – a 1mm end mill should run at 20,000 in steel, but I guess 19,000 is close enough). The cutting part in this case is around 5mm.

I've had the joy of breaking a number of the amazon end mills and one of my two APT mills.

I can't quite work out what is the trigger for breaking and end mill. In one test I made a slot in steel 3mm deep, 1mm across and 15mm long with no problems (about 0.3mm DOC). In other tests I am less aggressive (so I think) and 'sping|' away goes the cutter.

Best success so far (relatively speaking) was cutting a 0.4mm deep slot across about 30mm of aluminium (1mm wide) with the APT cutter. This went fine (see later), but right at the end of the slot as it immerged from the metal,'Sping!', the APT one went.

One thing what was disturbing with APT one was a strong signing. If I move the bed slowly it would be intermittent (so contacting the metal, rebounding, contacting and so on). going faster the singing was consistent.

I think that this was mainly due to the stick out of the mill. The barrel is very long and hits the end of the collet internal bore. With my next one I will shorten the barrel.

I'm really looking for general advice on this. Are the cheap cutters really going to work on steel? Should I just buy lots of mills as they will break?

I should say that the mill is substantial (for a hobby – a VM32L, around 240KG) but manual, so my irregular handle turning may be a factor.

Hope this makes some sense.

Iain

Iain Downs.