Posted by Andrew Skinner on 28/12/2022 12:31:12:

What I have is backlash between drive pulley and spindle.

That is play in the splines.

There is not a lot you can do to eliminate it other than remanufacture the mating parts.

You can mitigate its effects by biasing the spline against the pulley. Have a search for 'Bridgeport spline play' or similar terms to see what solutions others have adopted.

The machine has spent most of its life rotating in one direction, so the wear will be asymmetric. Buy a whole load of left hand cutters and use the unworn part. If you can turn the splined part of the pulley upside down, that might give it a new lease of life.

You can make a keyed collar that goes over the spline and is joined to the pulley with a spring wrapped around it such that it pulls the parts together. See picture in post #9 here:

https://www.practicalmachinist.com/forum/threads/how-little-clearance-should-milling-machine-spindle-splines-have.339379/

The above solution should not affect use of the quill.

That thread mentions a Downham jig borer that has an anti-backlash system, so look there for inspiration. Also look at anti-backlash gears (HPC have them – two half-width gears biased open with springs).

Another option when you are taking intermittent cuts is to clamp the spindle and pulley together. This disables the quill, but you can put the cut on with the knee.

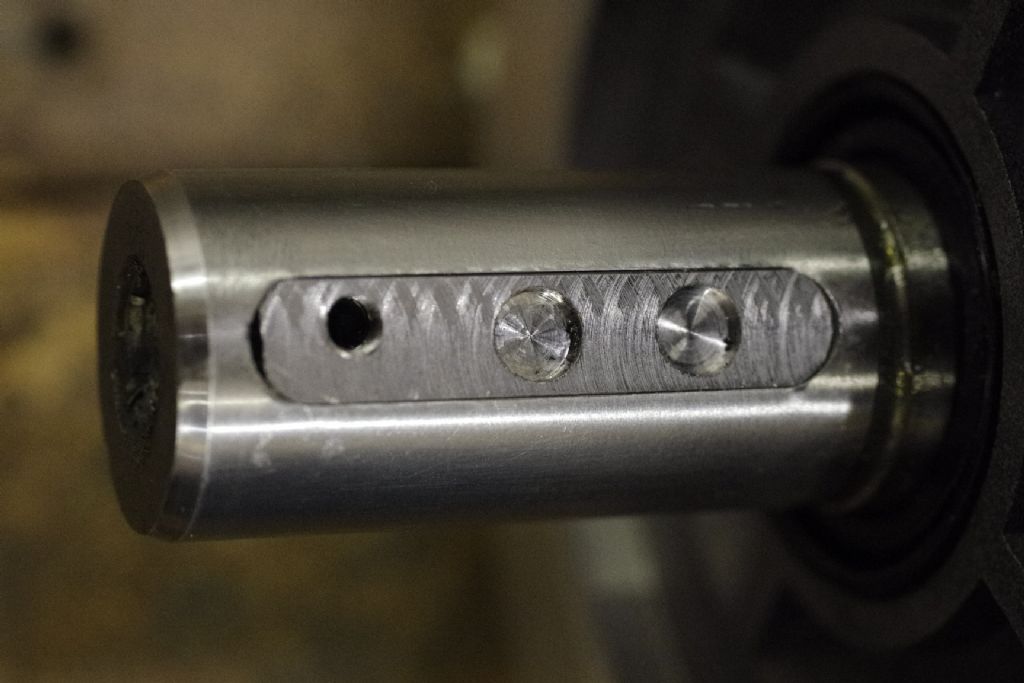

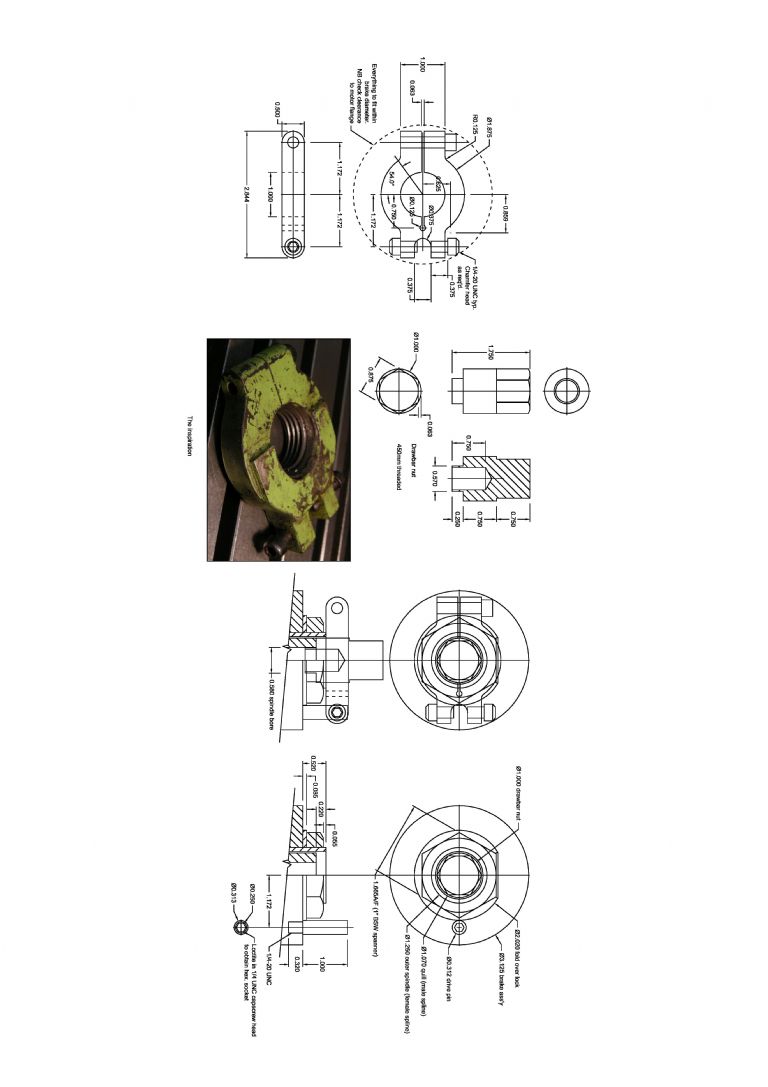

Below is what I made to address the same issue on a Beaver. The pin stays in the pulley; the 'drive dog' clamps round the plain portion of the drawbar.

Edit: also search for 'anti-backlash spline' as there are some patents that might inspire you.

Edited By DC31k on 28/12/2022 13:17:12

Andrew Skinner.