Posted by SillyOldDuffer on 09/06/2023 18:11:04:

Posted by Chris Blight on 09/06/2023 16:59:13:

…

Is it part of the original machine? If it is any idea what the lettering on the plaque means?

Not part of the original machine. Likely an asset or inventory number. An interesting possibility is the lathe was fitted to a ship sometime during or after WW2. Shipbuilders worked with Yard Numbers, not names, because names were were allocated later by owners. (The Titanic was Harland and Wolff Yard No 401, and the QE2 was John Brown Yard No 736. )

Most vessels of any size had a decent on-board workshop, and a lathe was essential.

The 1939 date on the motor refers to British Standard 170, not when the motor or lathe was made. No matter – the machine is still approximately of WW2 vintage.

Dave

Thanks for the information. Very interesting if it was on board a ship, adds to the history of it. I figured, given what you and others have said here, that it started life around the WW2 era and I'm curious as to the history of it all.

Any help with the plaques etc would also be a help. Not sure how I might go about making those things from scratch, it would be a lot of work regardless.

An update on the restoration. I was packing most of the parts away until I was able to give more time to it, but then found the head sitting there, way too heavy to lift and to awkward to park on a shelf with the limited equipment, so decided to start restoring it instead. Took everything apart, spindle, pulley shaft, inter shaft, gears etc…cleaned the casting down, stripped off the bearings (7 – 4 BB, 1 Roller, and 2 Angular Contact) , and found them all worn like a bag of nails. It seems that they were the original bearings; Hoffman and R&M, British manufacture, expensive at the time I would guess, given that if you can find them they are very expensive now.

Hoffman and R&M got bought by RHP, which is now part of NSK, such are the machinations of the corporate world.

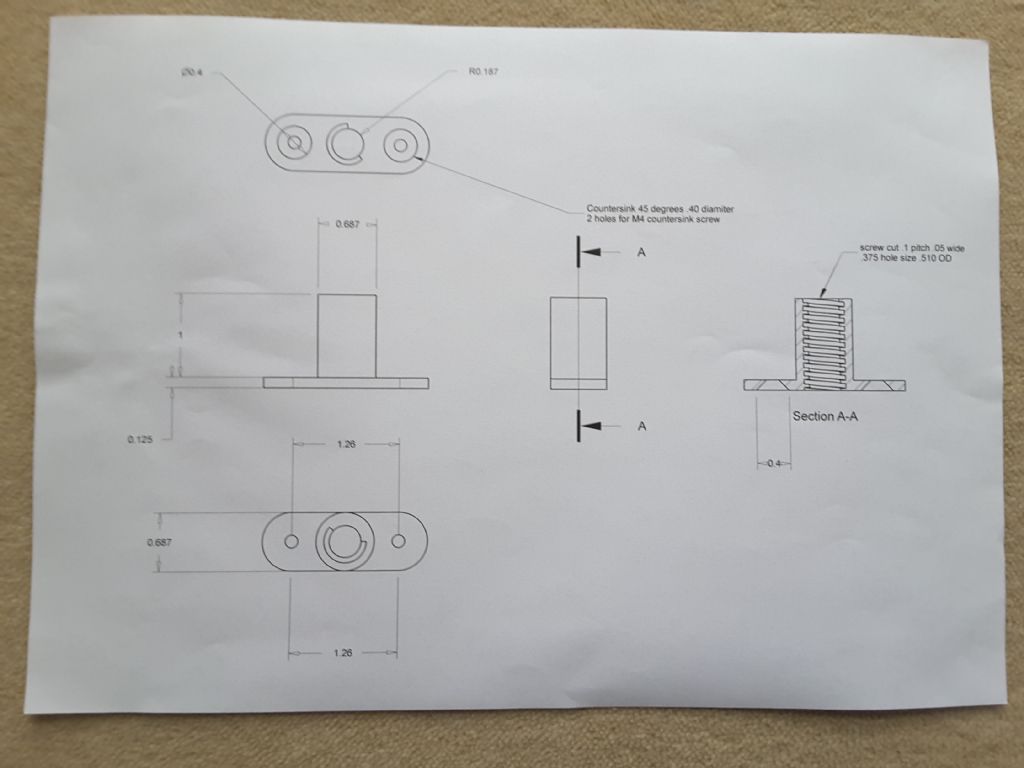

Anyway, having bought a couple of bearings I'm finding that the sizes are slightly larger; 0.0005" on the OD's and a little less on the ID's. 1/2 a thou is usually the preference for interference fit on bearings so decided to measure the bores on the head to find out what I was working with, found some surprising results, bores smaller than I expected. So, will have to grind the OD's of the new bearings so they fit properly, which isn't as much of a problem as it is a PITA, and timer consuming, but not as bad as re-boring the head.

At least you can buy Imperial bearings these days, or the metric equivalents. Just can't afford to buy RHP bearings for all the replacements. Will probably buy NKE for the AC spindle bearings but even they are £60 at least for one. I have bought one Hoffman bearing so I could check the size of it, just to make sure the size difference wasn't because it was an old British bearing.

I wonder if bearing fits/tolerances were different back in the day, maybe that's why I'm seeing different sizes, or they built the head and shafts around the bearing sizes they had then. Some of the bearings did have their sizes etched on them.

I've re-sprayed the head casting and decided that the handles were getting a coat of paint as well, as they were badly corroded. Still working on some aspects of the spraying process and haven't got all the photos of it yet, but promise they are coming.

The plaque I asked about before I took off while I was looking at the bed and stand. I'm also going to restore that so it gives me somewhere to put the head when it's finished.

Chris Blight.