I have recently acquired a Boxford ME10 here in the States from a friend who knew almost nothing about it other than how to turn it on. The number stamped on the bed is Me10-a-73816 and it has the imperial lead screw.

Its a nice piece with the power crossfeed, gear box, and coolant pump, and doesn't appear to have been overly abused, but its got some problems.

First problem I've encountered is that someone has fitted a larger drive pulley and rubber belt to the countershaft, and now it is impossible to get the Spindle Drive belt tight enough to not slip when taking even moderate cuts. The sheet metal of the belt housing has already been shimmed up to clear the larger pully but its still not enough to get adequate tension. I have contacted Boxford and was informed that the correct pulley is no longer available and they don't have the drawings to even tell me what the correct sizes are so I could possibly have a pulley made. Does anyone know where I might find the correct pulley or even what size it should be?

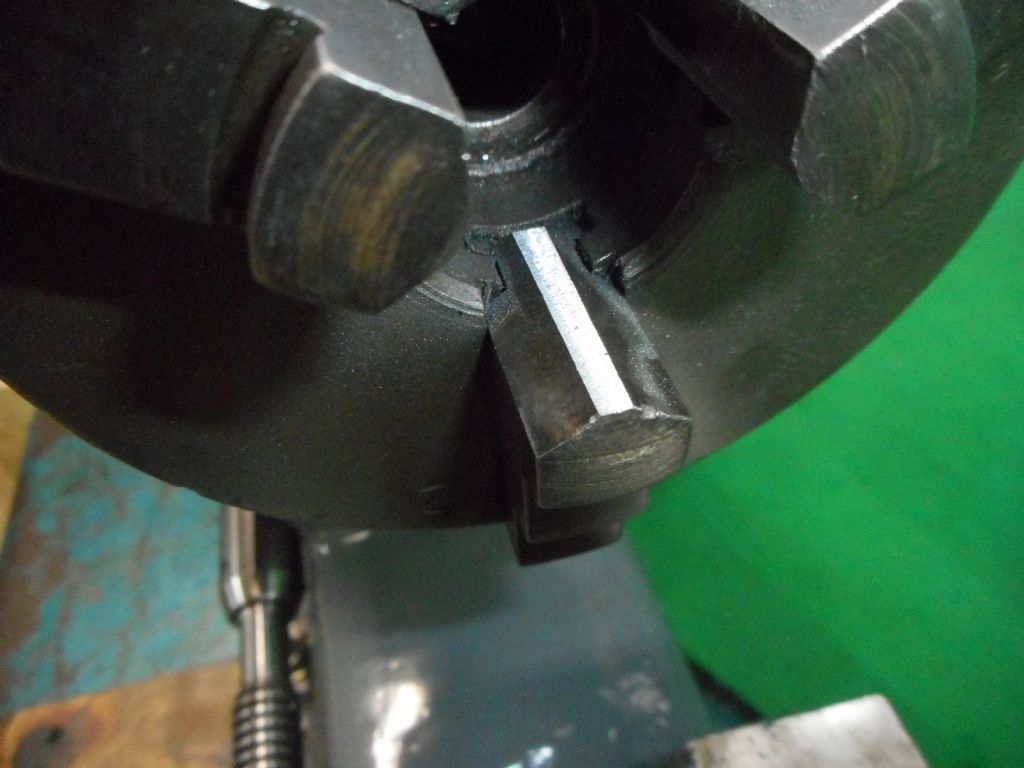

The second issue I have seems to be with the 3 jaw chuck. I have .012-.013 runout 3" from the jaws. Putting an indicator on the spindle shows no runout, and indicating on the body of the chuck shows a little less than .001, but I've got a repeatable .012-.013 on multiple precision ground rods at 3". Measuring the rod with the jaw at 12 O'clock, Jaw 3 shows .000, Jaw 2 shows .011, and jaw 1 shows .009. I have completely disassembled, cleaned, and reassembled the chuck making sure the jaws were in their proper place. I got no change. I have checked for bearing issues by chucking a long rod and wiggling up and down with an indicator on the chuck body and got 0 movement.

I would be okay with having to replace the chuck but from what I've read I believe my spindle should be 1.5" 8tpi Whitworth and I have so far been unable to find a replacement or backplate.

The last issue I'm having is locating a steady rest that will fit the bed and work with the 10" swing.

Dave Halford.

Dave Halford.