Posted by Gary Clarke 4 on 21/04/2022 15:35:26:

I have one of these kits lying around waiting to be installed. I have seen the buried tape in the crosslide before but have not seen the buried head in the saddle before.. is there a video or pictures or guide for doing that? Neil, if you could document your installation, that may be helpful for others like me!

thanks!

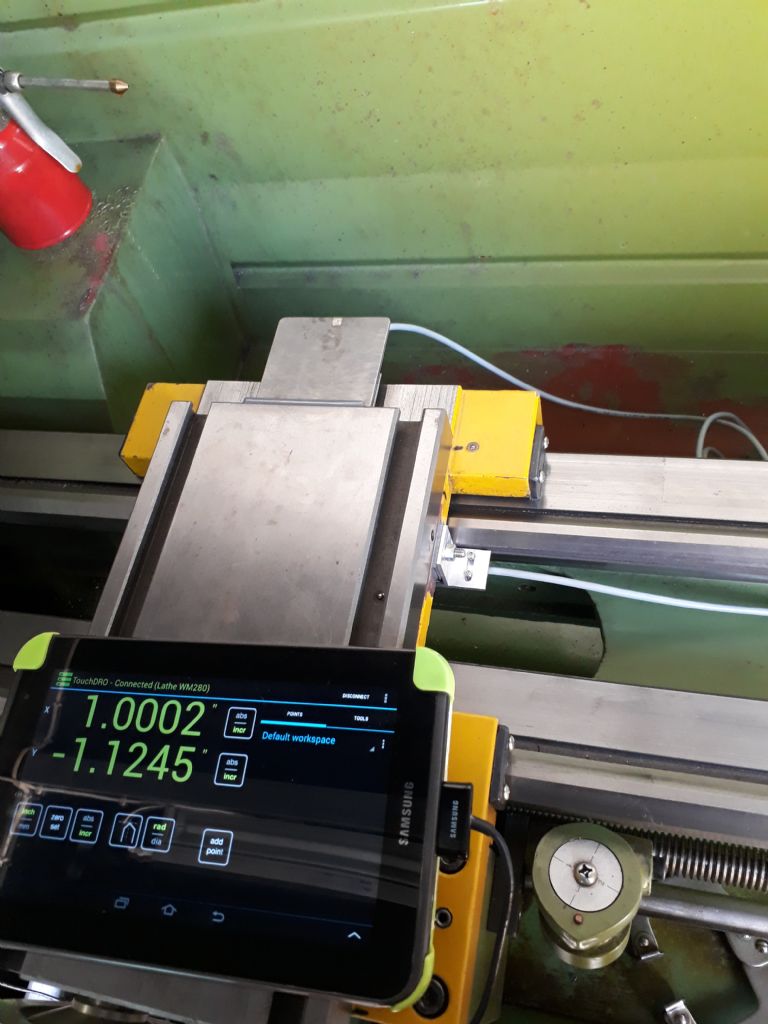

I just took some pics sort of as I went along. I placed the tape into a piece of 22 wide x 20 high on 2 sides x1.5mm wall section, extrusion cut the near full length of the S7 bed. The tape is cut about 50mm longer than needed so the reader head was always well inside the tape length. The extrusion is held in place by the 3m 19mm wide high strength double sided tape, placed at each end of the extrusion for 100mm long. The lower bed section is cleaned with brake cleaner degreaser. The end hand wheel is removed to allow easy access to slide the extrusion with the tape on down the bed to the very end. The end of the extrusion sit hard against the gearbox. Lightly place the extrusion guessing level. Using a low pressure indicator, travel the length of the bed aligning the extrusion to being parallel . The best i could achieve was 0.03mm as the extrusion is seldom even that straight over its length. Press the extrusion more firmly to the bed checking each time and correcting as needed. Over time the tape adhesion will increase. I used another extrusion siting back over the initial extrusion to act as a cover and guide for the reader head. Before starting, made sure that there was enough room for the tape, protective cover plus the reader head with a gap all fits. Mine was the slimline series reader head. All assembled the reader head has from 0.2mm to 0.3mm of clearance to the tape. The cover piece that holds the read head is mounted into the end piece cut from the length and is about the length of the leadscrew cover to the other side of the carriage long. I removed the thread dial indicator as I have rarely ever used it. The 2 M3 screws that secure the readhead to the cover plate, also holds the adaptor spacer to cover. The adaptor space was just 2 pieces of another extrusion put together. To enable the assembly of that bracket, I used M4 nuts super glued to the inner surface so the screws could be easily assembled. The main holder piece is a but of 3mm section ali extrusion 20x20x3 that I had. When assembled the guide just rests against the main tape holder both front and back. In my case the alignment for a and aft was better than 0.06mm which was totally un planed and was an afterthought and oversight. Only with issues did I check that alignment value.

There are more pictures in my album of the details of the read errors and the bits and assembly. The double sided tape is really strong and the most movement pulling back on the extrusion is only 0.02mm and that is a lot more force than the extrusion will ever experience.

Now it will be removed before the tape becomes almost impossible to remove and I move on and look at getting something else. I will price the availability of the Newall scale today and go from there. I do like the new Sino LCD DRO though and see if it's compatible with the Newall scales.

I may have just a bad set box, and bad magnetic tape too. I am no longer looking at fixing this solution, but going to something more industrial and robust that will still front mount and I will make another sliding cover for the newer setup.

Neil

bernard towers.