Many thanks to Chris Robinson!

In February 2016 i asked in this place for background informations about a gear train capable to produce prime number gears.

http://www.model-engineer.co.uk/forums/postings.asp?th=115116

At http://www.lathes.co.uk/ i found a version, which was equipped with a differential gearbox helping to produce prime number gears. The first answers didn't help. So i decided to make a copy of the jacobs

hobbing machine with o normal gearbox.

But in my mind a wish list with two features was still opened:

1. Creation of a planetary gear in the form of a bevel gear differential.

2. Additional supplements to enable helical gear manufacturing.

As far as part 2 is concerned, I am not yet surely determined, since another way by making a connection with one of my dividing attachments with my Milling machine in the sense of a spiral milling device would also be an acceptable way.

The implementation of Part 1, however was difficult to understand, in particular the mathematical

Conditions. After several months' waiting time the author of the article in http://www.lathes.co.uk/,

who is the only one having created a differential gear for the Jacobs machine found my questions and agreed

to help me, especially giving informations about the mathematical foundations.

Thus there was no longer any obstacle to dare to build.

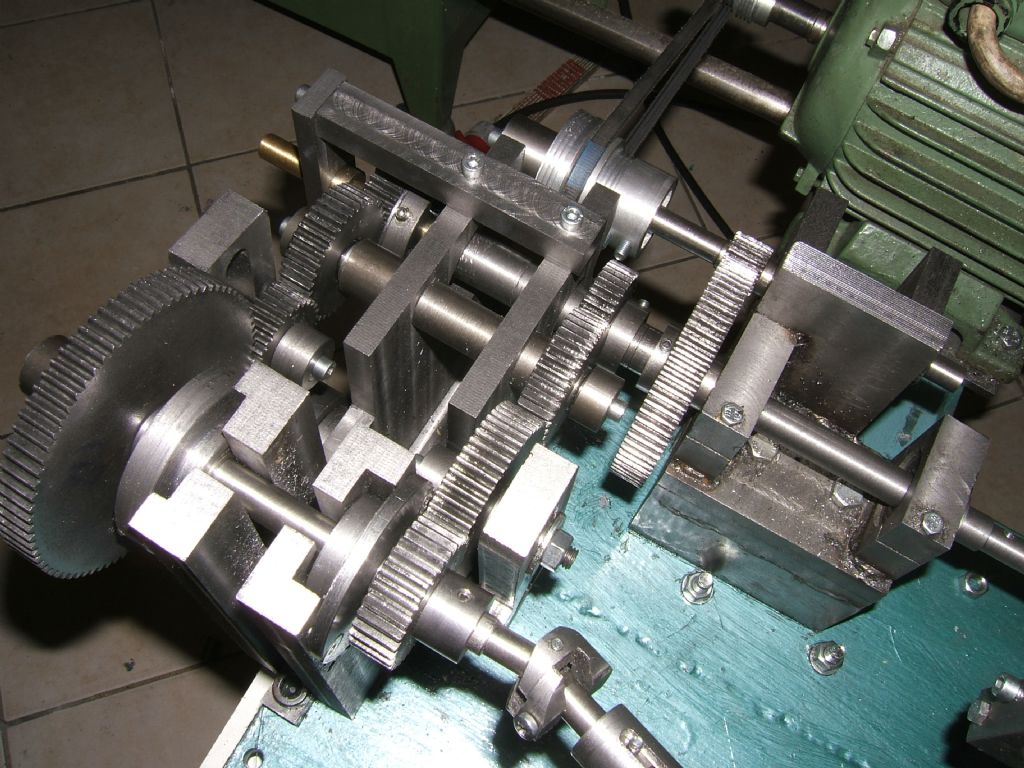

For the bevel gear differential, 4 identical bevel gears were used according to the method of Ivan Law

(20 teeth, module 1), the corresponding spur gear with 40 teeth, module

1.25.

A second shear was quickly created. The first disappointment followed at the same time, as the two

shears proved to be very unstable. A somewhat bumpy run was only possible with hand- and power-

Support. After all, the fundamental running was given.

Thus a more stable gear set-up had to be achieved.

Thus a more stable gear set-up had to be achieved.

Compared with the examples on MEW, an additional idler gear on each side was required, because I had right turning hobs and I wanted that the hob was turning towards the gear blank.

Due to the fact that a fixed size was assigned to each intermediate wheel on each side, a relatively short and stable shear was provided for the second variable idler.

On youtube you can see the machine hobbing a 127 teeth gear.

Youtube: https://youtu.be/M4jmJ65aI0Q

Edited By JasonB on 17/02/2017 15:03:14

celso ari schlichting.