They are good at producing flat surfaces – pretty extremely flat if the ram is any good. The finish compared with the simple end of milling can also be better – it's a sort of flat lathe so can produce work with the same degree of finish.

They can be used to make dovetail slides by attaching rope come string to lift the tool on the return stroke. Getting it wrong can make a bit of a mess. I've seen that happen.

They can cut keyways. Internal ones need the cutter on a bar that can pass through the bore and if blind ended they need to run into a hole or slot etc.

Angled work without much complication.

The main reason they fell out of use is metal removal rates even on big meaty ones that can take a rather large cut. Mostly down to using a single point tool and only cutting in one direction. Plus want a better finish stick it on a grinder. Flatness isn't so simple.

I have a nice little one but no room to erect it.

I have a nice little one but no room to erect it.

John

–

Edited By Ajohnw on 16/09/2016 14:21:45

Edited By Ajohnw on 16/09/2016 14:23:08

vintage engineer.

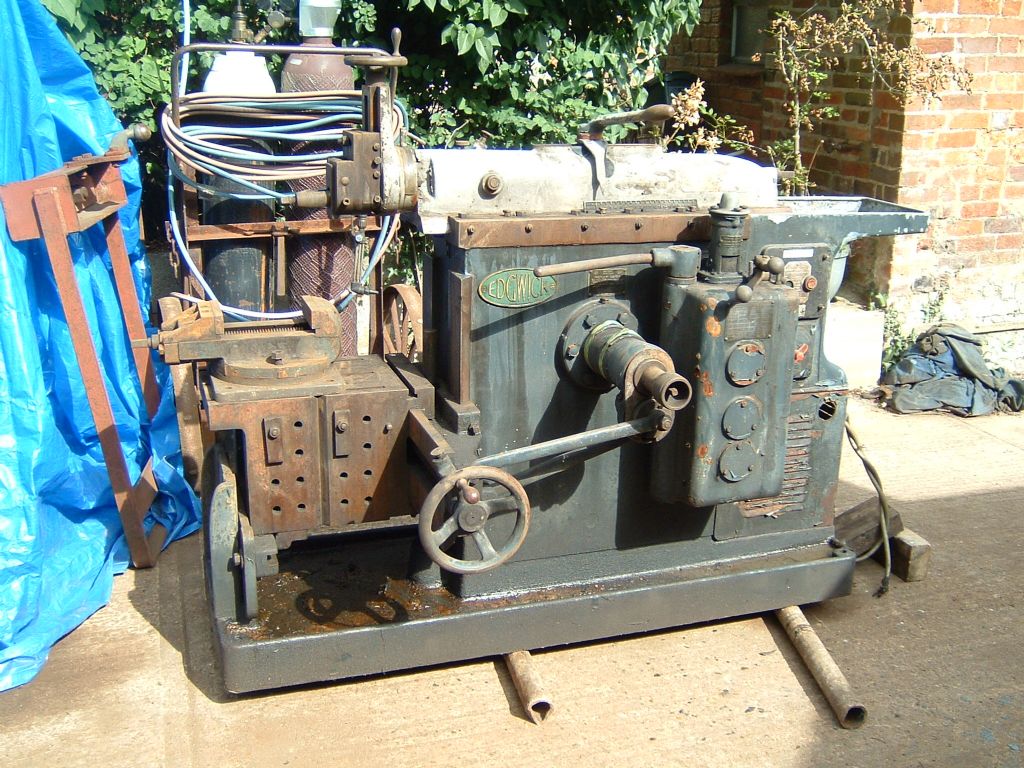

This is the sort you want.

This is the sort you want.