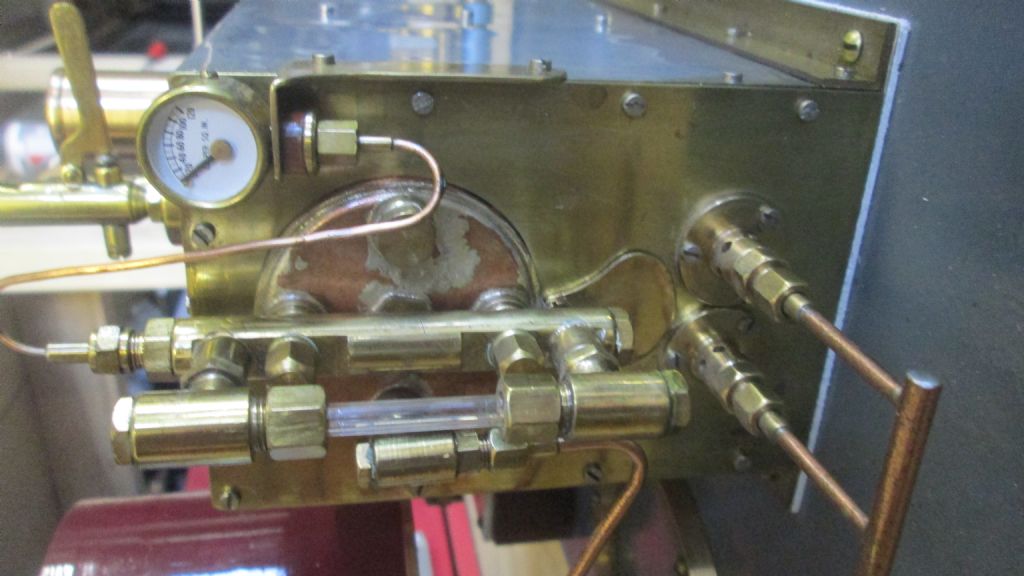

When a boiler is first tested by an inspector, it is hydraulicaly tested to 2 X working pressure, so a 120 psi gauge suggests 60 psi as the normal operating pressure.

Subsequent, usually annual, tests pressurise to 1.5 X W P.

The boiler inspector wil also check that the Safety Valve can release stean faster than the boiler can generate it.

Re safety.

A pressure vessel failure can be very injurious. A small boiler may not necessarily be a "widow maker", but it could be!

Even if the metal does not fragment with the danger of shrapnel flying about, the steam contain a LOT of energy.

At 60 psi, the steam temperature will be well above 100 C, probably nearer to something like 170 C.

For every gramme of steam that impinges on you, there will be 70 calories released as the steam cools from 170 to 100 C. But the real damage will the steam condensing to water; each gramme will release 536 calories, as it condenses to water at 100C.

So the quantity of heat released from Steam at 170 C hitting flesh at 37C will be about 670 calories PER gramme

And a gramme is a small unit of weight, so in reality, there would be a much greater weight of steam flying about.

That will be sufficient to strip skin!

So be VERY careful!

First job, in my book, would be a hydraulic test to 1.5 W P, probably 90 psi, (This will require various fittings to be renoved and blanked off ) followed by a steam test to 60 psi, to check the safety valve.

Howard

Martin Johnson 1.

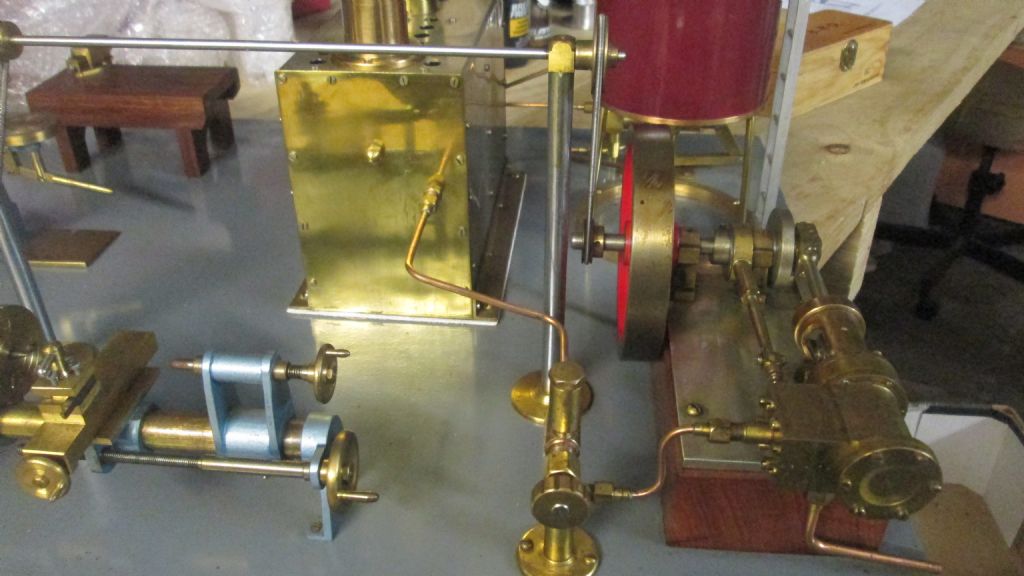

coming from the chimney that would otherwise be clear when gas fired. It will also help pull a draft and keep the flame healthy. The lower the safety valve is set the more you'll see 'steam' in the exhaust plume.

coming from the chimney that would otherwise be clear when gas fired. It will also help pull a draft and keep the flame healthy. The lower the safety valve is set the more you'll see 'steam' in the exhaust plume.