Posted by Hopper on 01/02/2023 22:42:53:

Posted by S K on 01/02/2023 21:04:54:

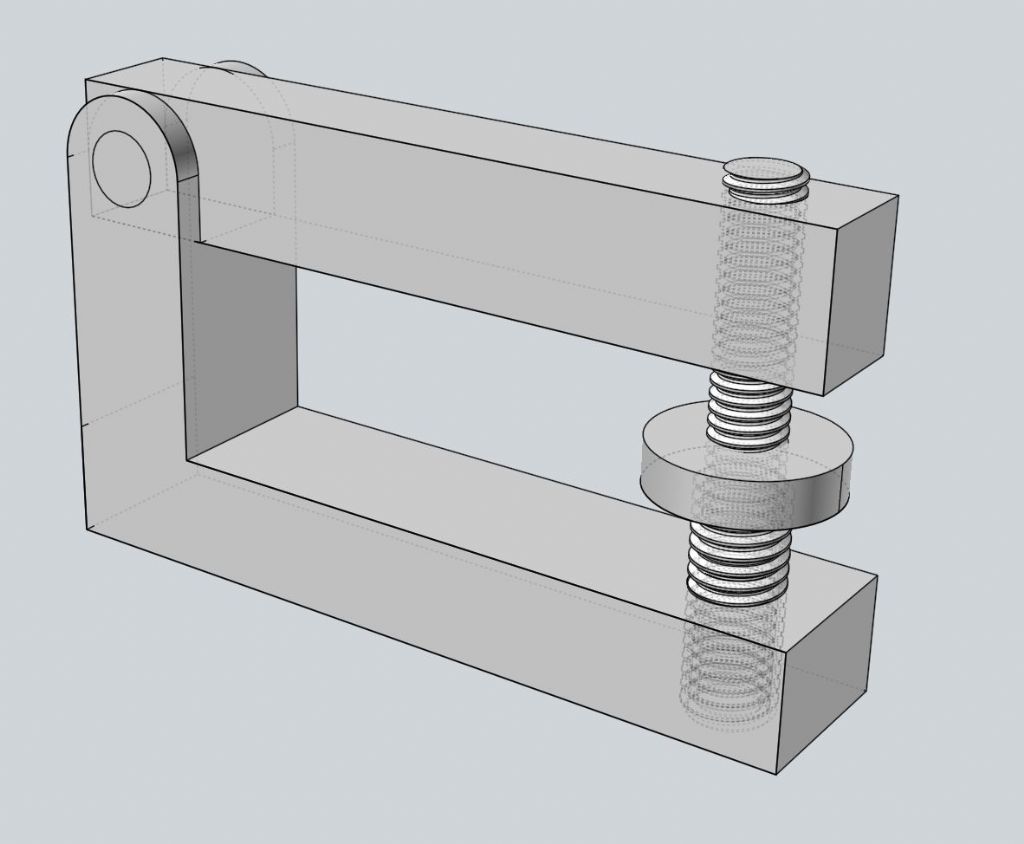

As John Haine will surmise, this is to level a pendulum that is hanging on knife-edges.

If that is the case, then surely clockmakers have done this very thing many times before and have established models that could be copied?

…

It has been done before, but my books mention it mostly in terms of disadvantages, and don't give any practical constructional details. From memory, the bearing is prone to wear and easily disturbed.

The closest analogue I know of is the old-fashioned Chemical Balance of the beam type, in which the fulcrum is an Agate edge. My school had four, studied briefly because the history of accurate weighing is important in chemistry, but we weren't taught how to use them in anger – chemical technique had moved on. Agate is harder than steel, and I don't know what the edge rested on – maybe a 'V' in another hard gemstone. Each scale lived in a front-opening glass case, I think levelled by four ordinary screw feet; my memory could be faulty!

I don't think chemical balance construction helps SK much because the scale's fulcrum edge was only put in contact with a lever whilst actually weighing. Most of the time it was lifted off. As there are over 30,000,000 seconds in a year, I don't know how long a sharp edge would last swinging a heavy pendulum bob.

On the subject of levelling, the support can be pretty crude as long as it's "good enough". A mechanically sophisticated way of levelling my clock has been on the TO DO list forever, but this is how it's done at the moment:

Though this abomination is levelled within the accuracy of a Wixey, about 0.2�°, balancing a pendulum clock on a stack of coins isn't Horological best practice! I only get away with it because my bob is tiny and swings well below the clock's centre-of-gravity, close to the base.

Dave

Edited By SillyOldDuffer on 02/02/2023 10:39:03

S K.