As Andrew says the great thing about using full profile inserts is that the thread cut is exactly correct so the depth of cut needed can be taken directly from standard tables. The perfectly formed crest is, to me, merely a minor advantage. I tend to trim the crests slightly on customer jobs as the small flat is more durable when the fitter has "shade tree mechanic Bubba" tendencies. I have almost full sets of Johansson / SKF / Dormer chasers that were commonly used on capstan lathes which produce the full form and can, in home workshop terms, be re- sharpened infinitely.

If you do decide to use partial profile or sharp point inserts you will need to calculate the extra depth of cut needed over book value for the thread you intend to make to accommodate the longer tip. A decent CAD program makes dealing with the geometry much easier. The basic dimensions and geometry of threads can be found in most handbooks but handbook writer union rules seem to demand that the diagrams are too small for easy reading. A decent size one for 60° UNF (American) threads can be found here :-

**LINK**

UNIFIED SCREW THREADS

By setting out a "nest" of diagrams in a CAD program its fairly easy to see what you need to change. For all practical purposes metric threads are the same.

I strongly advise using the "Zero-to-Zero" thread cutting method if you plan to use partial profile or sharp point inserts because it makes it very easy to reliably set the required changes in thread depth. So much so that its practical to work by trial and error slowly increasing depth of cut over book until a satisfactory fit is obtained using a good quality nut or accurate test piece made using a good quality tap.

Having found the correct in-feed for that thread and that insert you should make a note of it so you can immediately make the requisite changes in set up when doing another thread of that size.

The reliability of the Zero-to-Zero method means that the thread will come out right first time, every time if you have the correct in-feed values.

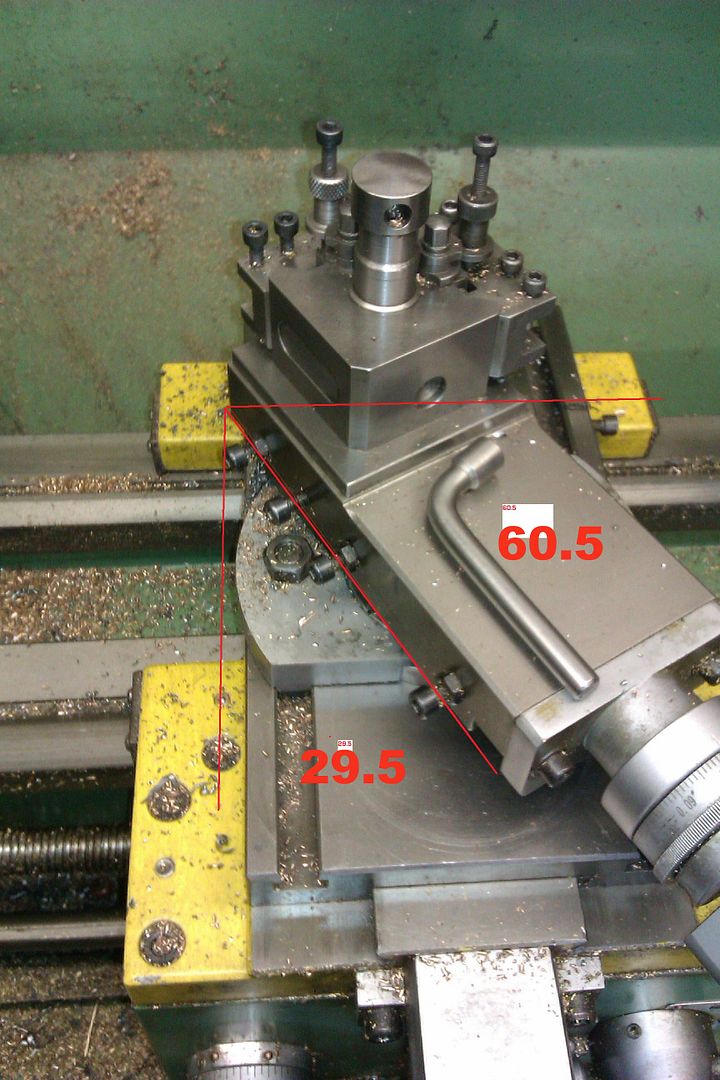

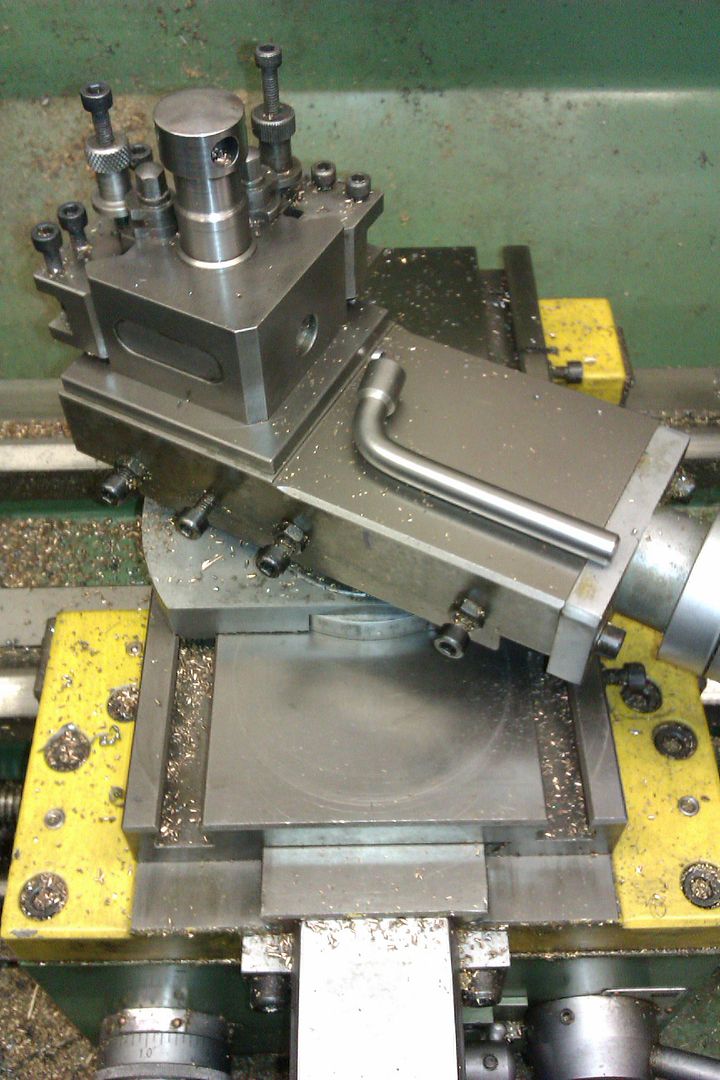

The Zero-to-Zero method is classically explained as a way of getting the lathe to calculate the correct in-feed when the top slide is set over at, or close to, half the thread angle. This avoids trigonometrical calculations. Generally considered a good thing. However the method works just fine when the top slide is set parallel to the cross side too.

Because all the setting up is done before you start the job goes easier as you only have to keep an eye on the process rather than worrying about feeds, sizes and things. Setting up at the start means what you set is what you get so if the thread doesn't fit you know what you have and have a solid starting point for working out what …… went wrong (this time!).

In simple terms you start, as usual, with the job cut to the required diameter and tool tip exactly perpendicular to the job.

1) Touch the tool tip to the work then set both top slide and cross slide dials to zero.

2) Pull the tool back a bit using the cross slide, traverse it past the end of the job then feed the cross slide forward past zero by the depth of thread you intend to cut.

If using a sharp point or partial profile insert and intending to find the correct depth by trial and error use the book value for thread depth. If you have already figured out what the actual depth needed is, use that.

3) Re-set the cross slide dial to zero and pull back the top slide to just clear the job.

4) Make the cutting passes with the cross slide at zero, pull it back for clearance when returning ready for the next cut then move it forward to zero for the next pass.

5) Apply cuts as appropriate using the top slide.

6) When all spring cuts have been worked out with both cross and top slide at zero what you cut is what you set.

If using book values with a sharp point or partial profile insert this will not be deep enough.

7) Make extra cuts by feeding the cross slide past zero leaving the top slide set on zero.

When the fit is correct the cross slide dial will read the extra depth of cut needed beyond book values. Add this to the book value and make a note of the result to give the correct depth of cut to set at step 2 when you next have to cut that thread with that insert.

Note that any damage to the tip will upset the calculations and results. Errors will almost invariably be too shallow a cut.

Partial profile inserts from different makers may not have exactly the same shape so if you change insert breeds you may need to alter your personal table of results.

Full profile is lots less faff. But spendy.

Clive

Edited By Clive Foster on 04/11/2022 13:57:34

old mart.