A couple of thoughts, on which I hope others will expand.

I had a similar problem when I bought a part completed Quorn tool & cutter grinder.

The main spindle ran beautifully, with a decent standard of workmanship, but the internal taper for the grinding wheel arbor was off centre.

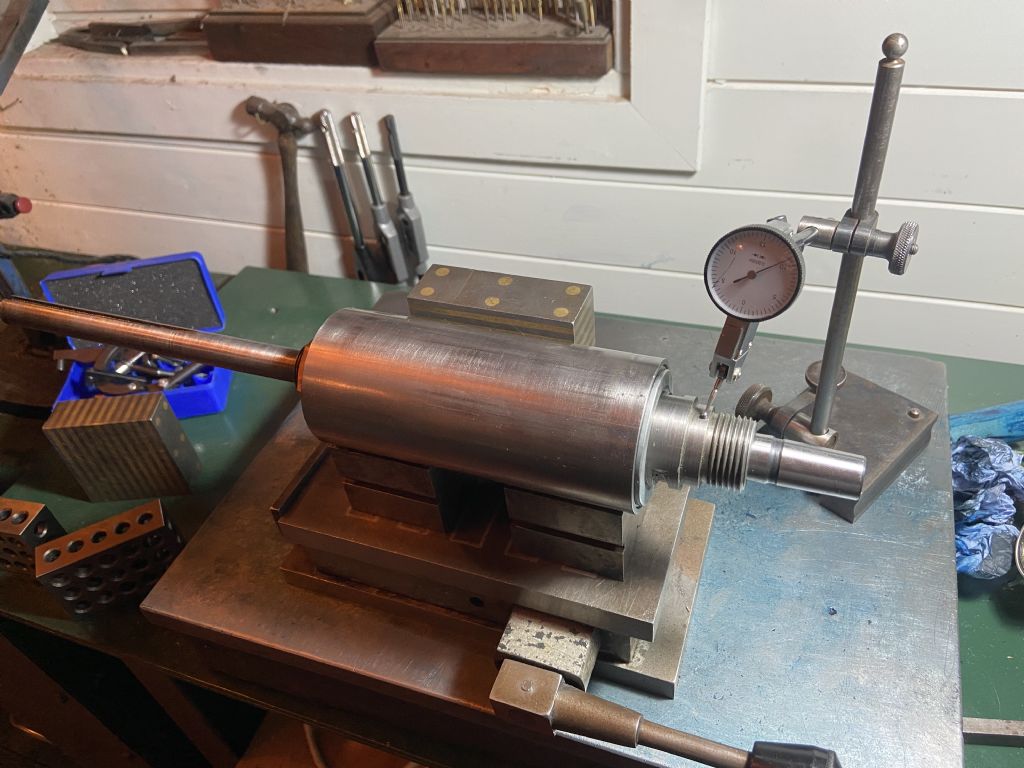

I cleaned all components, and re-assembled the spindle into its housing; the housing is essentially a bit of steam pipe bored out to suit, with bearings at each end.

I then set the housing in the lathe using two fixed steadies, and clocked everything to centre height, square etc.

I used the lathe chuck to drive the spindle in its own bearings, and re-machined the taper.

It's only a short taper on that so a fairly simple job.

Whilst the top slide was set over, I also made a load of spare arbors with a matching angle.

In your case, you could do the same thing, but that would leave the external chuck register wrong, and maybe the Morse tapered hole too deep.

You have a drill chuck arbor there, which is likely to be concentric and accurate, as well as being centre drilled.

Is the outer chuck register off in the same direction as the MT2 internal taper?

Also, using a test bar, is the taper parallel to the axis of rotation, but just off centre?

If so, how about removing all of the outer components of the quill, add the arbor into the taper, and run the centre main spindle between centres.

You could then re-machine the spindle's surface(s) where they touch the main bearings.

A shrink fit, or loctite'd sleeve could be added and re-machined concentric.

You might get lucky and find a speedy sleeve to fit to make up the difference.

Another possibility might be to convert from imperial to metric bearings or vice versa, and re-machine accordingly

It is possible to carefully re-machine a very small amount off the inner or outer diameter of ball/roller bearings.

Bill

Neil Lickfold.

)

)