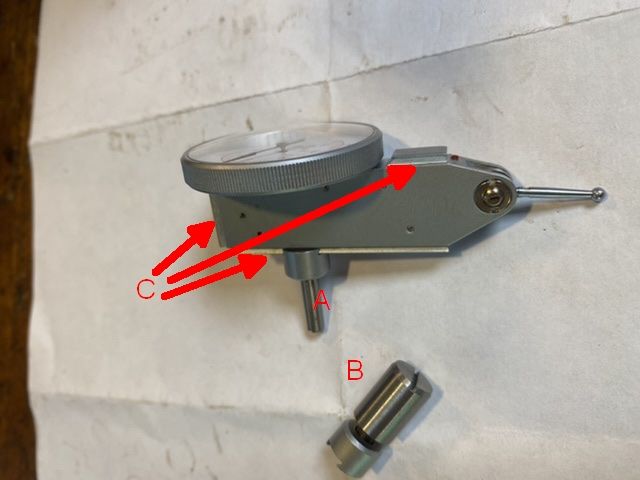

You have what is often called a Finger clock.

I think that you have a Myford, so will use Imperial dimensions, although the same technique applies to Metric

It has finer graduations, but a more limited range than a plunger type clock. There are two adaptors that will fit on the the dovetail (As S O D's pictures show ) to mount the indicator onto the "monkey block" that clamps the indicator onto the long shaft attached to the column of the magnetic base.

Keep the indicator as close to the vertical column, to maximise rigidity.. If the indicator is not firmly fixed, you won't get consistent and accurate readings.

No sense in try to measure accurately from a datum point that moves about

Presumably your initial intention is to use the clock to centre work in the four jaw chuck.

(If you use it check work in the 3 jaw, you find that there is always some eccentricity, which may well vary according to the diameter of the work being held. )

Assuming that you set the clock to bear against the top of a round bar n the chuck, you centralise the clock about the bar by moving the Cross Slide to and fro to find the point where the clock reading is maximum (You should aim to set the clock so that is pre loaded by 0.010" (0.25 mm) The reading will decrease (The needle move anti clockwise as you move away from the highest, central point )

Initially it is likely that the work will be so far off centre that the indicator loses contact, at one point, and is taken to or beyond the extreme at the opposite point.

Adjust two opposing jaws until the indicator stay in contact with the bar, even if it flickers to and fro..

Then repeat the adjustment in the plane at right angles.

Keep rechecking that the clock is centred over the work. Every time that you adjust the jaws to centre the work, you are moving the centreline of the work, so a recheck is needed..

Eventually, you will have the bar near enough to centred nfor the clock to remain in contact all the time, but with a mfluctuating reading.

Remember that when you get a reading of the eccentricity, you adjust to remove HALF of the reading.

So, having set the clock to Zero (At the lowest point perhaps ) if the total reading is 0.010", you adjust the upper jaw to reduce the reading to 0.005" Probably you will need to rotate the chuck to access the adjusting screw for the opposite jaw, so that one jaw moves In and the other moves out.

Repeat in the other plane and hopefully the excursions of the needle will have decreased quite markedly.

Don't forget to reset the Cross Slide to put the clock over the repositioned centreline..

Repeat these actions until the eccentricity readings decrease to what you think is an acceptable level (I normally try to get to 0.0005" or less, but that's my method of working )

It has taken longer to type this than to explain / demonstrate in a face to face situation, so do find a club and join.

And the books suggested will reinforce, and explain, the advice that you have been given.

You will learn a lot quite quickly., in this way with far less frustration and puzzlement.

Howard

Edited By Howard Lewis on 02/07/2022 17:22:21

Chris Murphy.

![20220702_175643[1].jpg 20220702_175643[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/909556.jpg)

![20220702_175704[1].jpg 20220702_175704[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/909557.jpg)

![20220702_175744[1].jpg 20220702_175744[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/909558.jpg)