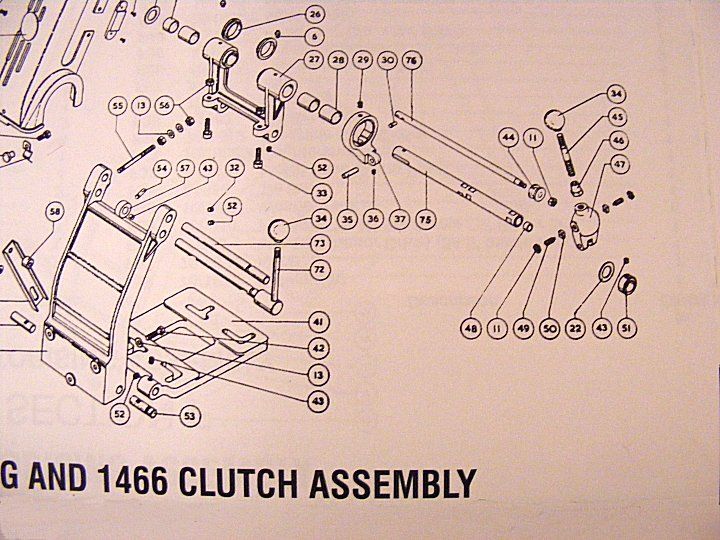

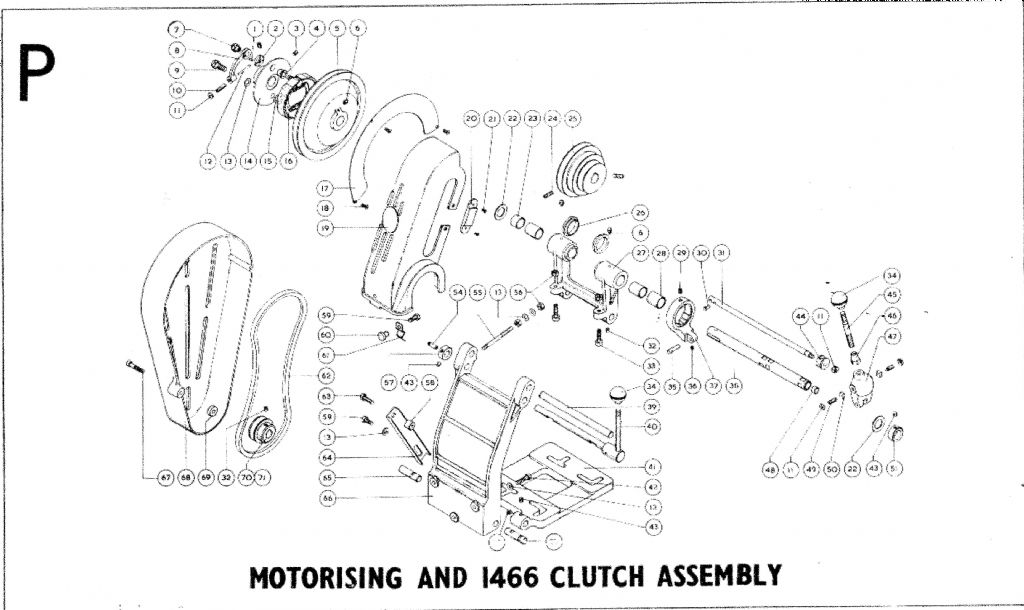

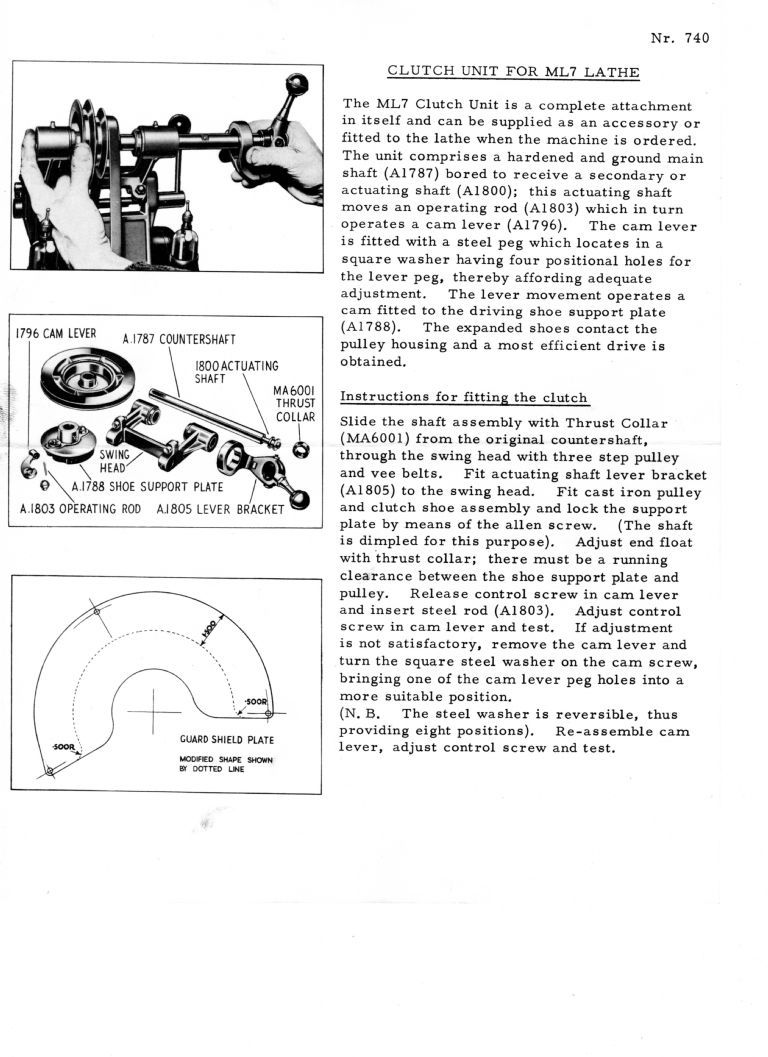

There is a bit more to adjusting the clutch than screwing the screw in and out. See below.

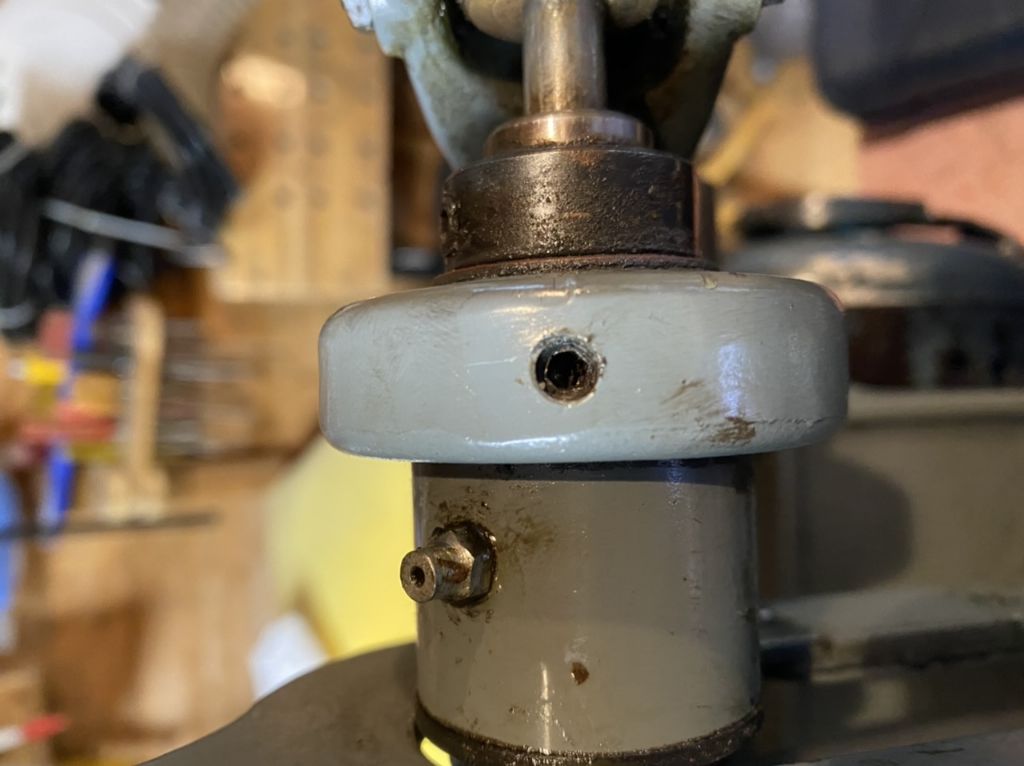

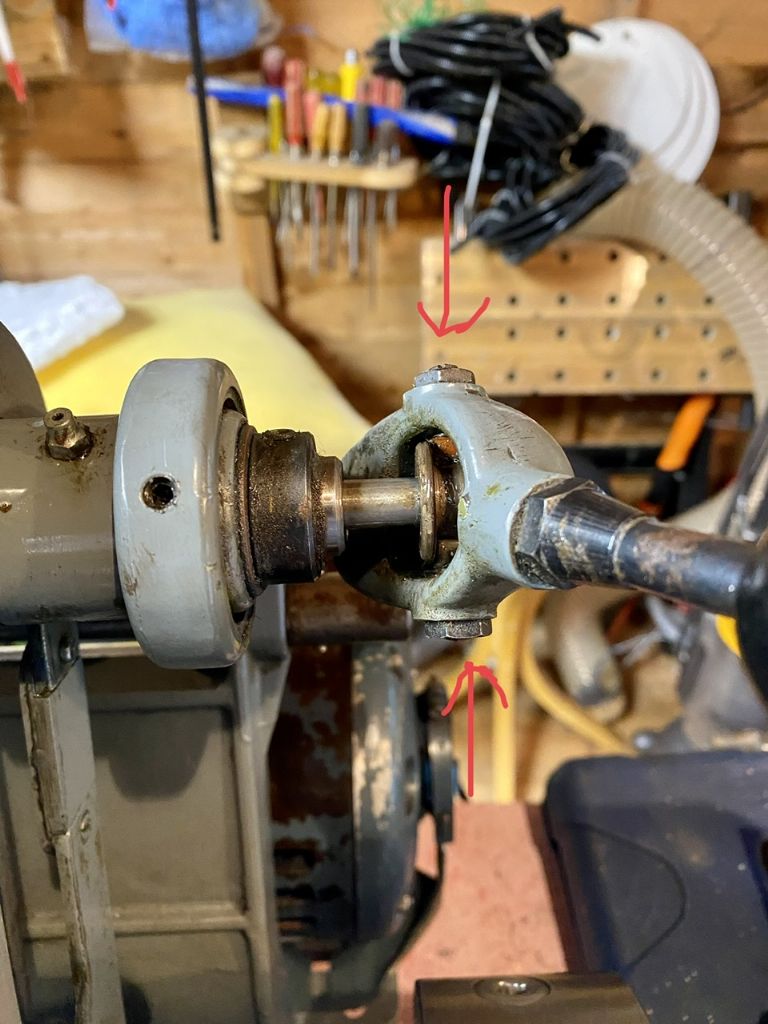

Note also where it says make sure there is clearance between the "shoe support plate" (aka moped front brake plate!!) and the pulley so it does not drag (and cause the chuck to turn). This end float is adjusted by the thrust collar, presumeably by the grub screw,which appears to be in place in your pic. It has that sunken hex head recess down in the hole.

This end float adjustment may well explain why when you push the lever, the chuck stops turning, because the lever pushes the countershaft along and creates the necessary clearance between the shoe plate and the pulley.

Another thing it could be is the bushing in the middle of the pulley is dry of oil and gripping the shaft enough to turn it slowly when the clutch is disengaged. Might just need some lube, or some cleaning up.

If all else fails, turn the lathe over by hand with the clutch cover off and look and listen for what is dragging. Could be the backing plate on the pulley or could be the shoes on the drum. Then make suitable adjustment to establish clearance. That little pushrod mechanism that operates the moped brake is as mickey mouse a piece of engineering as ever graced a production engineer's desk and will need to be set just right.

Edited By Hopper on 01/06/2022 11:37:04

Edited By Hopper on 01/06/2022 11:41:29

Edited By Hopper on 01/06/2022 11:44:07

Edited By Hopper on 01/06/2022 11:50:12

Chris Murphy.