As others have said, buy some books on using a lathe .

Harold Hall, Ian Bradley. (The Amateur's Workshop, and the Myford 7 Series Manual ), Stan Bray, and L H Sparey (The Amateurs Lathe).

Books on the mini lathe have been written by Dave Fenner, David Clark and Neil Wyatt.

Neil also wrote a series on using the Sieg SC4 in Model Engineers Workshop, some time ago.

You do not have to have all of them, but more than one may cover some feature or technique not mentioned in the other(s )

Whilst some of the books deal with a specific machine, others do not. Every one will contain information on the basic principles, which can be applied to almost any lathe..

The advice to learn using the machine by making small items is good. Not only will you learn, (From mistakes as well as successes ) but you will have a small collection of tools that will be useful in the future. You start with simple, straightforward ones, and as you gain experience and confidence, progress to more complex items.

Possible items could be

A Centre Height Gauge,

one or two Tap Wrenches of different sizes,

Stud boxes for various types and sizes of threads

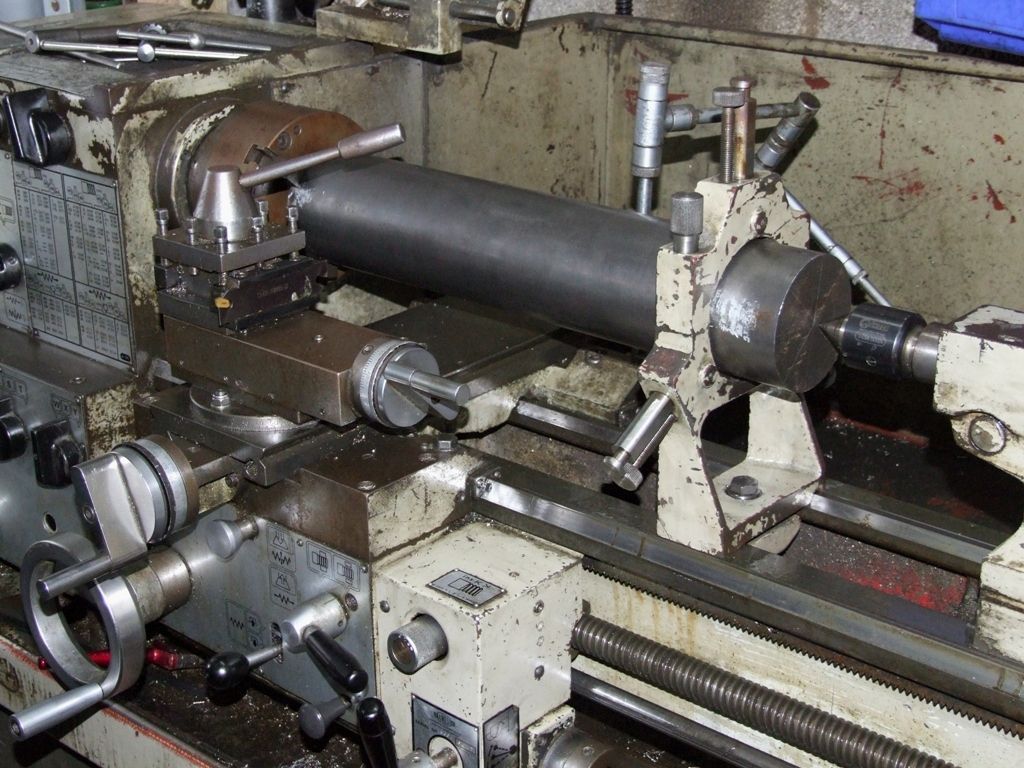

An Alignment Bar for when you want to check or adjust the alignment of the lathe, to remove twist from the bed, or to align the Tailstock

(Ian Bradley's books will tell you how to check and adjust the lathe to take twist out of the bed. A lathe with a twisted bed will be unlikely to turn parallel.

A second Centre, for when you want to centre work in an independent 4 Jaw Chuck

A Tailstock Sliding Die holder, (You can buy the Arbor and actual Die holders, just make the basic body )

More adventurously, a Tailstock Sliding Tap Holder ( Mine uses ER 25 collets )

A Mandrel Handle (useful when using Dies nor Taps in the lathe, especially when working up to a shoulder )

To make these items, you will need measuring equipment, probably a calliper (Digital, Dial, or Vernier ) to begin, or a selection of Micrometers.

With a 4 jaw chuck you will need a magnetic base and at least one dial indicator. Often ntwo can be have their muses, a Plunger type and "Finger" clock, ( usually more sensitive, and can be used in a bore where a plunger clock cannot go )

You can make these tools as simple , or as complicated / decorative,as you wish as you progress.

In the future, you will ,find a use for all of these things, sometimes often, others less frequently, but still useful.

It is better to make mistakes (And even scrap a job ) in a piece of mild steel bar than an expensive casting from a kit.

Books like G H Thomas' "The Model Engineers Workshop Manual" and "Workshop Techniques" will give you ideas and provide drawings.

One final sombre note, THINK SAFETY., and be careful You don't have to go overboard, but just take care.

(Turn the chuck by hand to ensure that everything is clear before applying power. )

Don't leave a chuck key in the chuck, except when you are using it to tighten or loosen the grip..

Even a small lathe is likely win if you get entangled with it

And beware of sharp edges on workpieces or swarf

Howard.

roy entwistle.