Gents,

I have a work-holding question I'm hoping that you can help provide a solution to, please.

The material is a length of truck leaf spring, possibly 5160, roughly 3" x 5" x .330" thick.

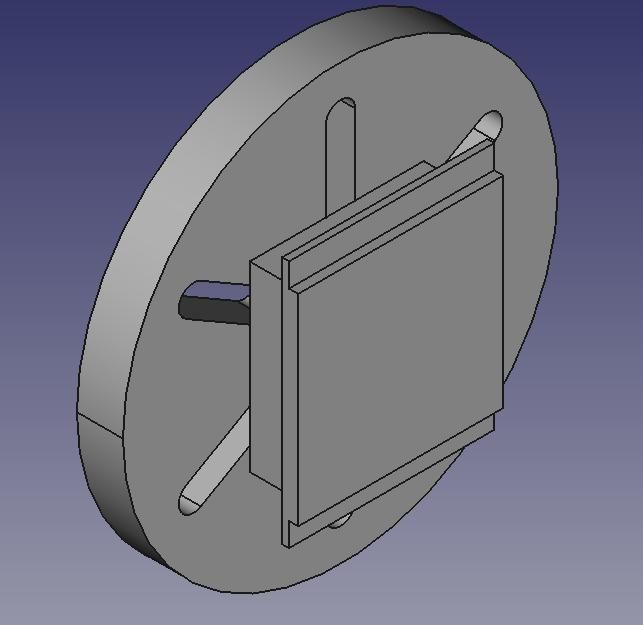

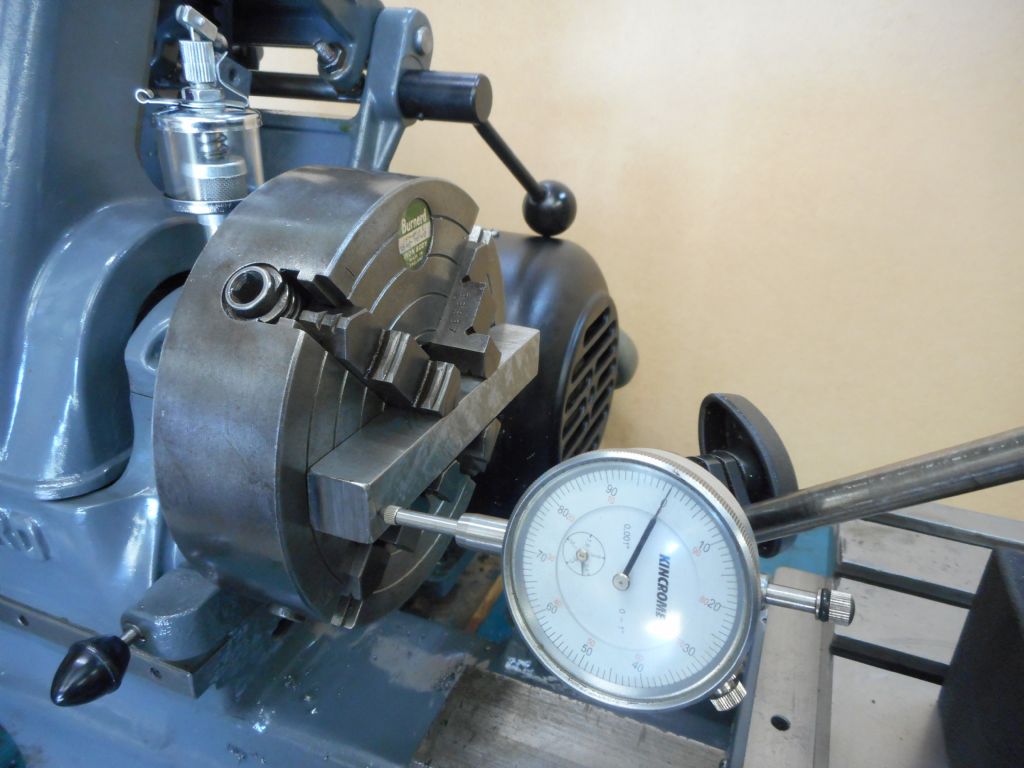

Is there a safe way, to either hold this in a 4 jaw chuck or hold it to a face plate for facing on the ML7?

The plan is to face it on one side, then flip it over and face the other side, machining down the thickness to .250".

Yes……there is an "arc" to the work piece as is, being a truck spring, but I will flatten it the best that I can in a 20 ton press before any facing or milling.

I've never faced material this shape nor of this size before……yep, a newbie just learning. The thought of facing this stock in an amongst protruding clamps or chuck jaws is somewhat daunting.

The other question I have, is a sharp HSS tool up to the task of facing 5160? Of course I have no way of knowing exactly what steel this truck spring cut-off is for certainty, only that it is spring steel and maybe it is 5160.

If this cannot be done on a ML7, I do have a Taig mill that I will attempt the same procedure on.

Thanks for your thots.

Anonymous.