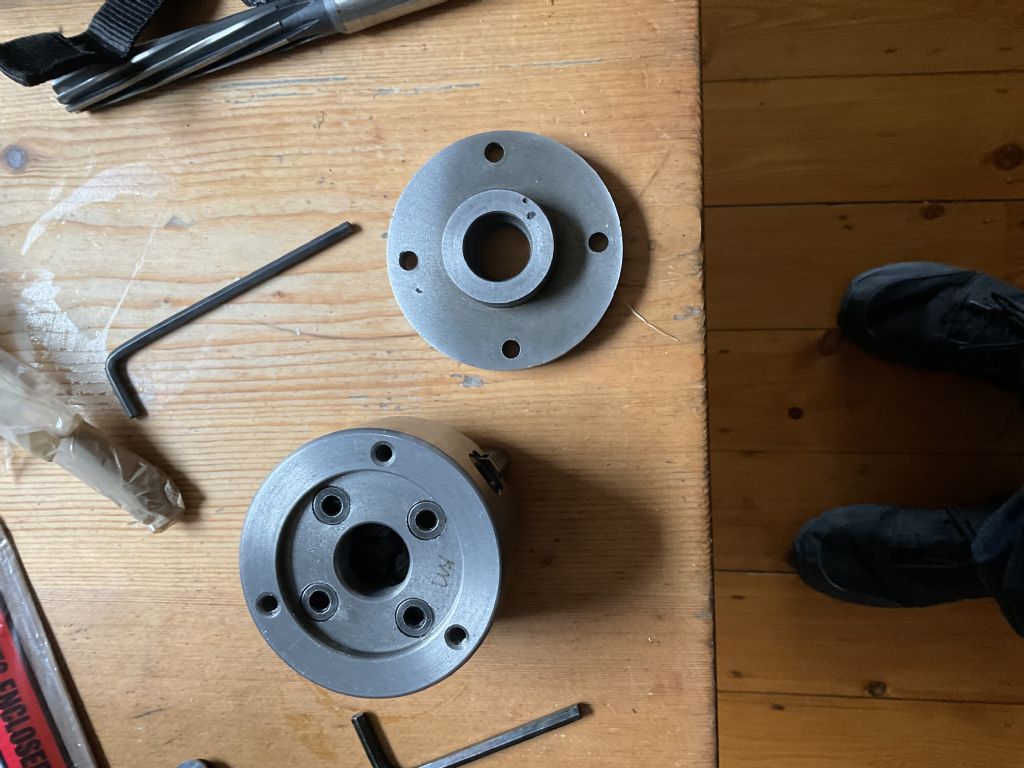

7/8 x 9 tpi is 7/8 BSW. From you mention of screws, it sounds like a 4 jaw chuck, rather than a 3 jaw..

If you fit the 4 hole backplate to the spindle, you then face it and turn the register to suit the new chuck, to ensure optimum alignment of the new chuck. It is unlikely that the register of the backplate will exactly match that of the new chuck, even if the face is absolutely square to the lathe axis.

If you can make two studs with the same thread as the tappings in the new chuck, with pointed ends, you can mark the backplate to drill to match the new chuck.

A 3 jaw will be quite adequate for this, if the new chuck is a 4 jaw.

Paint the backplate with blue, roughly where the new through holes will be.

Screw the two pointed studs into the chuck, far enough that they only just protrude.

Use a bolt, or stud and nut, in one of the existing holes , to hold the backplate to the chuck with the register just engaged.

The two pointed studs should mark the blue to show where the through clearance holes need to be drilled.

Drill the new two holes, deburr and you should then be able to fit the backplate to the new chuck, using studs and nuts or hexagon head setscrews; as you wish.

The freshly made face and register will provide the alignment, so the clearance holes can be a little oversize, if need be.

HTH

Howard

David-Clark 1.