Ok, I took a test cut Aliminium bar:

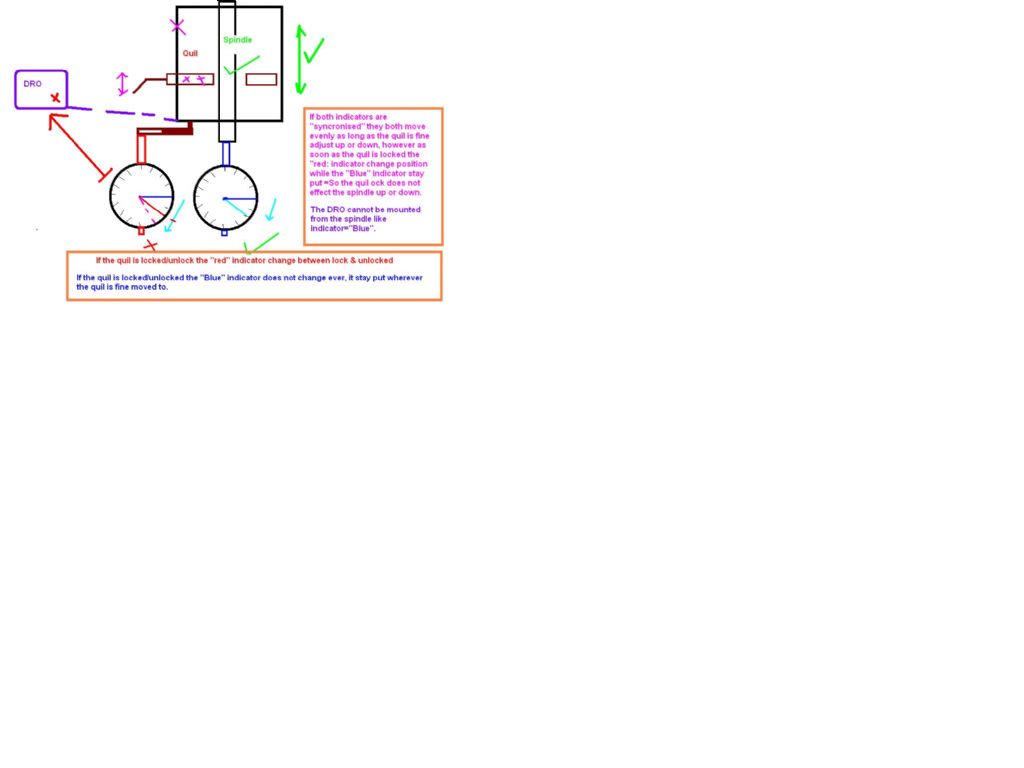

A-I Trusted in Mitutoyo Dial Indicator(Red in drawing) mounted to head, measuring the Quil up/down with the Fine Adjust wormgear.

B-From an in dept experiment between the two guages setup, I determend that if I got them syncroed, then chose a target measure lower it to that, the Red Guage of course not on target with Blue gauge.

-Now if I pump the quil lock lever between lock and unlock, I can step by step advance the Red Guage to the same value as the Blue guage that dont change with the Quil Lock/unlocking.

-So from this I trusted that by using the pumping action I can mill ok.

C-I remove the Blue indicator, and put the aliiminium bar in the vice & tighten/Hammer down, tighten.

D-I am now ready to chose mill a starting surface…I milled that once, back, twice, back, thrice..

—–I mark this setting as zero on Red Idicator(Mitutoyo).

—–I then move the quil up a bit, wind the X- Axis back and measure the starting diameter with Digital Calier.

The result is 39.66mm.

E-I am now ready to chose a cut= -0.066mm off.

-I carefully Lock the Quil-Pump, Unlock-Adjust, Lock-Pump, Unlock-Adjust, Lock-pump, Unlock-no adjust needed target reached.

-I carefully mil it Once, back, twice, back, Thrice, unlock adjust Quil up.

—Move X-axis way back so I can measure(Vice in centre)…

Result:

Start=39.66mm

Target=39.594mm (-0.66mm)

Measured=39.57mm………..(The 0.066, the last 6 I guessed.(Indicator-.01mm).

I think I am happy, let me know…My problem is the effort to get to that, this effort seems impractical and wrong to me.

Edited By Chris Mate on 24/03/2022 10:57:45

Edited By Chris Mate on 24/03/2022 10:58:45

Edited By Chris Mate on 24/03/2022 10:59:46

Y C Lui.