RDG's description of these as Titanium Slot/End Mills raised my eyebrows! Pretty sure they're not made of Titanium, or are the special type of cutters used to machine Titanium.

Not a problem though, because they're almost certainly the usual HSS coated with Titanium Nitride for extra hardness. Might even be the same set as the ones I have (not bought from RDG) which work well.

I only plunge and slot with 2-flute cutters. You can get 3-flute cutters which are sort of dual-purpose. (I want to try them but keep forgetting to order any.)

The problem may be asking too much of the cutter and/or the machine. Or that the metal doesn't machine well: unknown scrap is often nasty stuff and ordinary mild-steel a little difficult. Beginners may take a while to find their machine's sweet spot. It's some combination of RPM, cutting area, and feed-rate. Too gentle and too aggressive operators are both bad: cutters are rapidly blunted by tentative rubbing, and the machine may not be rigid or powerful enough to take heavy cuts. I set the RPM according to the diameter of the cutter, and don't attempt to go much deeper than 20% of tool diameter. Feed rate is done by ear – I like the machine to sound noticeably loaded but not labouring.

Lots of coolant is a good idea when slotting and it's essential to remove swarf. Mincing swarf is another super-quick way of blunting tools, and blunt cutters are poo.

Dave

SillyOldDuffer.

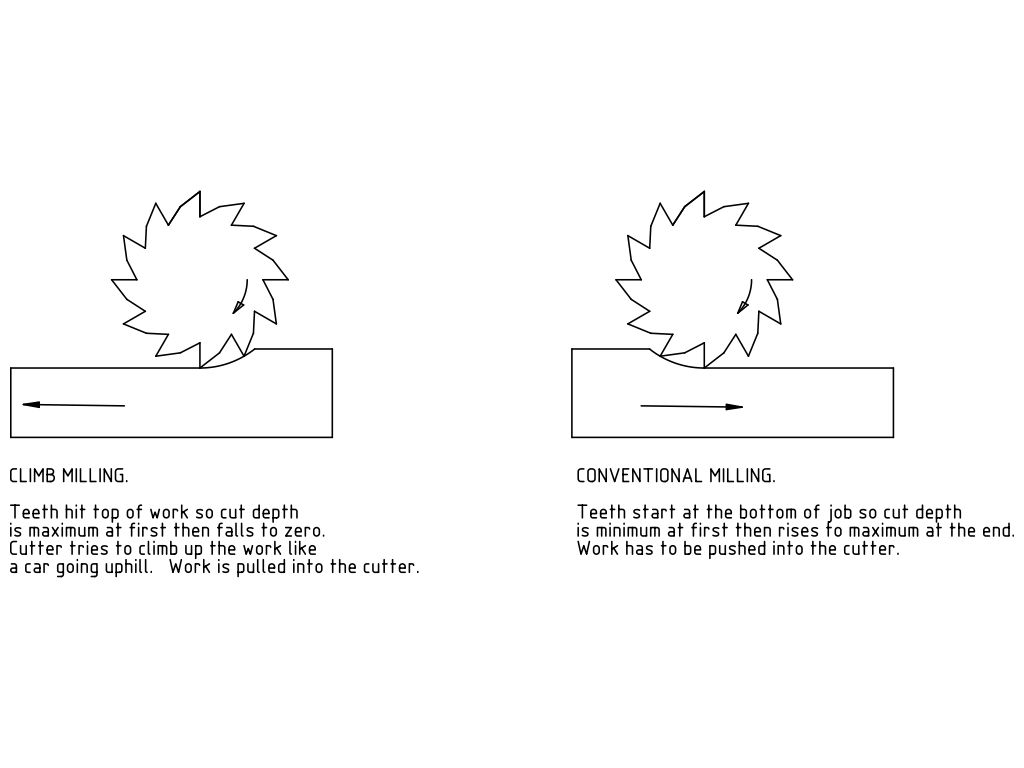

milling machines – a finish cut can provide a far better finish than conventional milling. Just need care – a light cut is essential.

milling machines – a finish cut can provide a far better finish than conventional milling. Just need care – a light cut is essential.