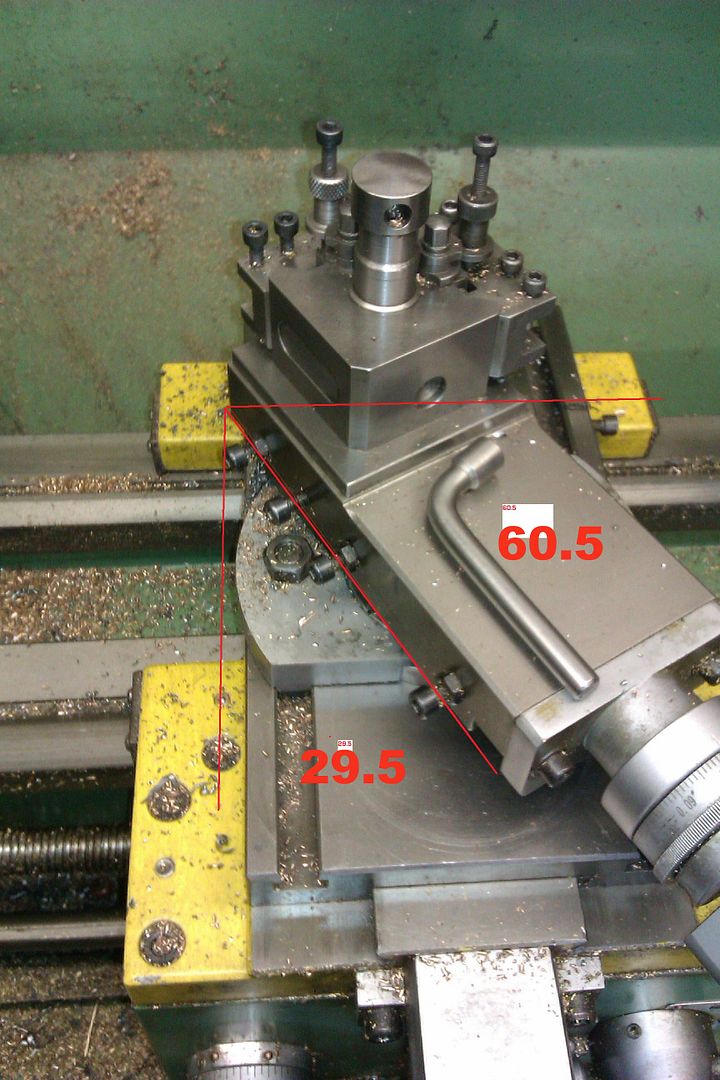

Thanks gents, it makes perfect sense to me now hopper, I have set it to 30 degrees from parallel, not from square to the job.

I wasn't a machinist back when I was an apprentice, but an apprentice fitter who had a good apprenticeship covering machining, welding, sheet metal work etc at a training centre for the first year with block release to college. Then back to the main company and put with a skilled man for the rest of my time, still with block release and day release to college.

All of this was 50 yrs ago and so a great deal has gone from my memory.

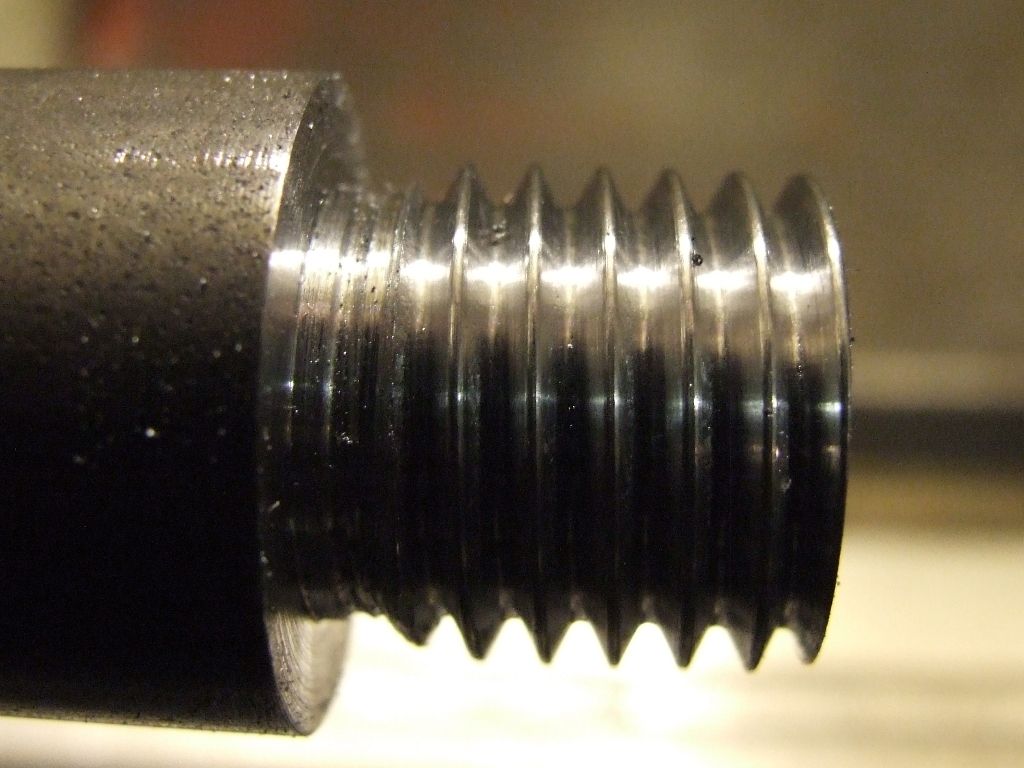

I don't think that I used the right word when I said advancing Tim, it's more not moving forward with the pitch of the thread, but seems to be lagging behind as though the cutting tool had been moved away from the headstock direction to the taistock direction all be it at an angle, with the compound slide rather than moved forward. If that makes sense, it 's rather difficult for me to describe it. Please forgive me.

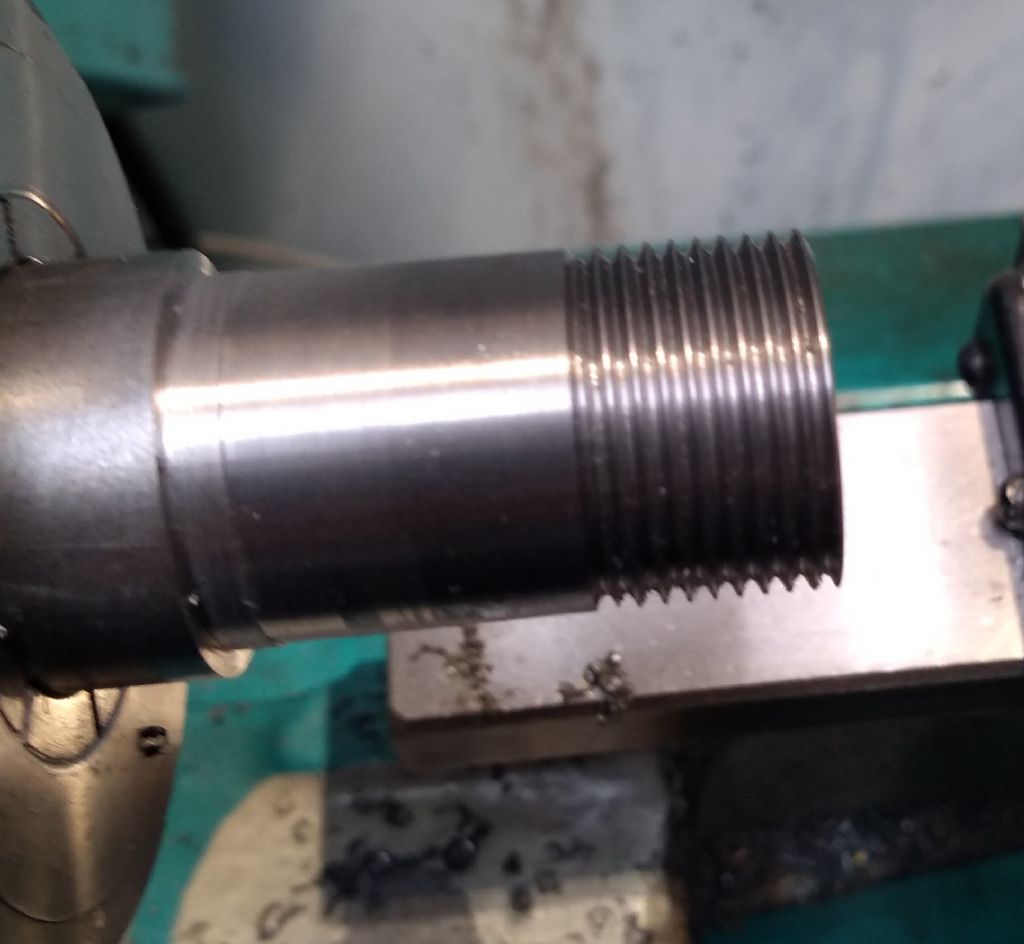

JA, I indeed put a scratch cut on to check that all was as it should be, after 1 cut all seemed good, so after 4 cuts and a look at the thread using a magnifying glass showed the problem that I had.

Thanks again for the great help that you have given me, I can get in the workshop and get it sorted out now. It's nice to know that there is always someone out there who is willing to give their advice gained from experience and knowledge.

Anonymous.