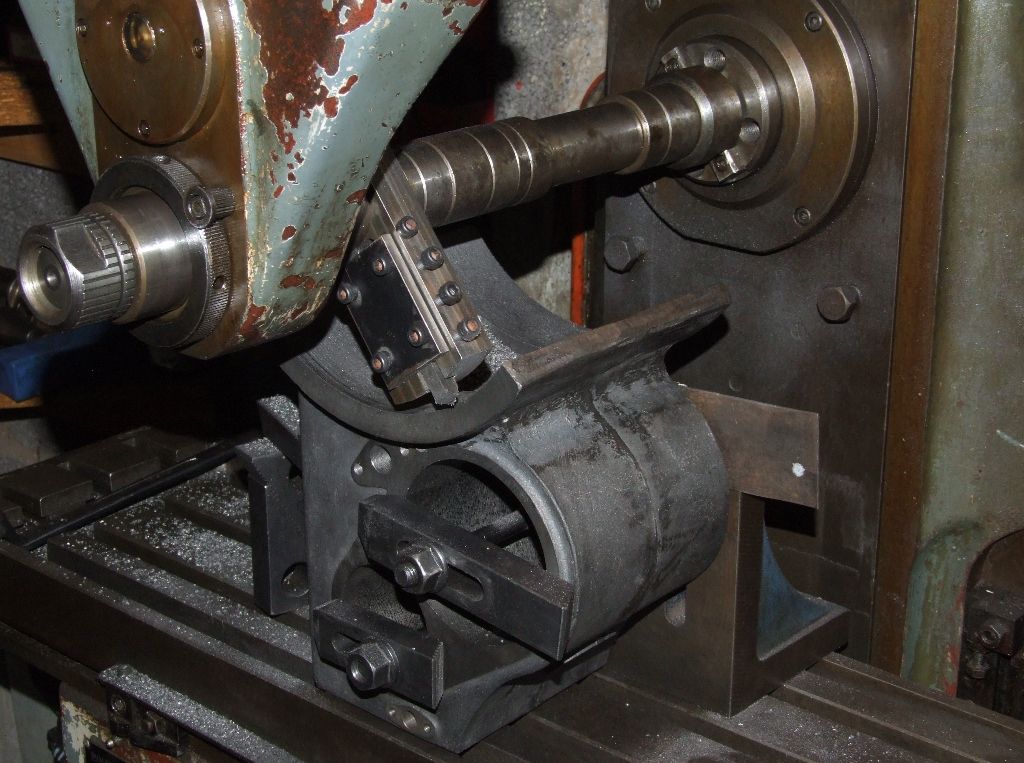

It was inevitable really that the proper fun and games would start once I had got it back together. Any mill manufactured in 1941, with bearings marked 1939 is going to be a challenge.

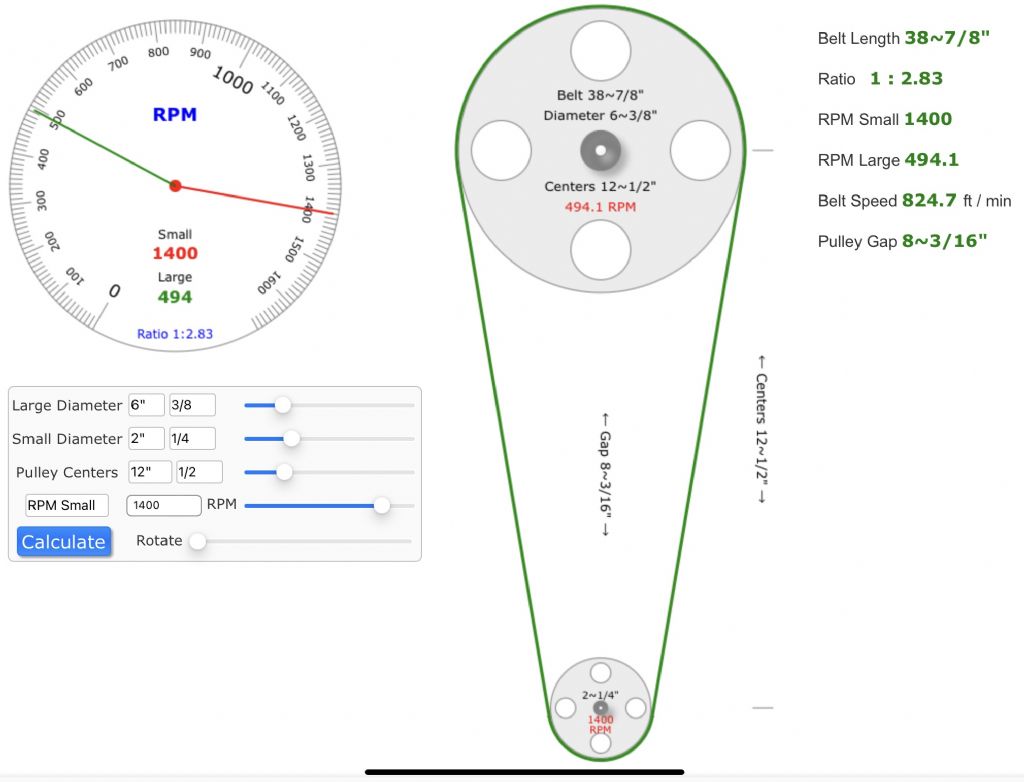

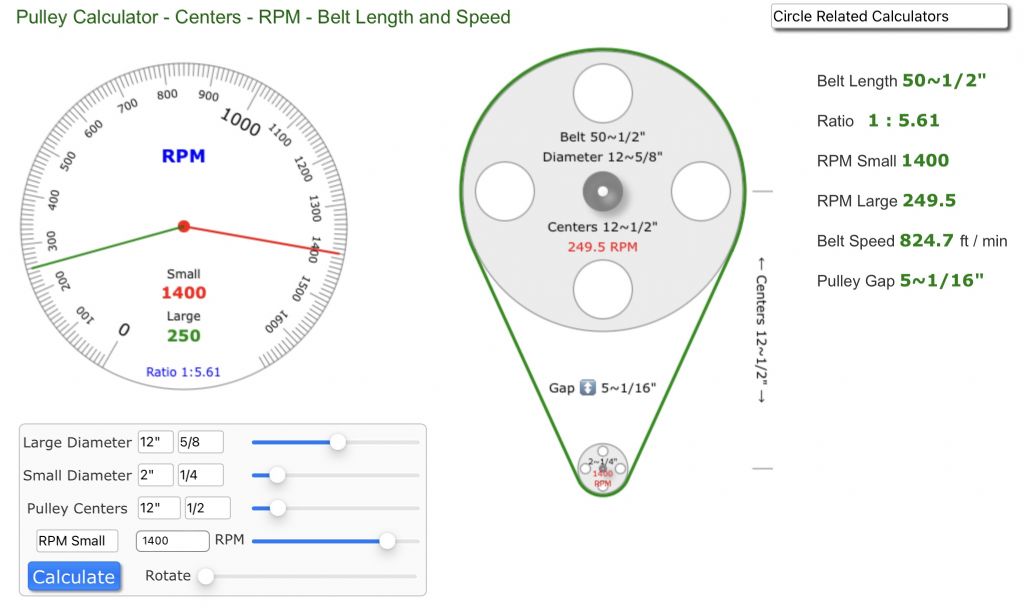

I have done some test cuts – not too bad but a little chatter and a “throbbing” noise which indicated (I presume) that something is not quite aligned right. I adjusted the belts which improved it somewhat, but it’s still there.

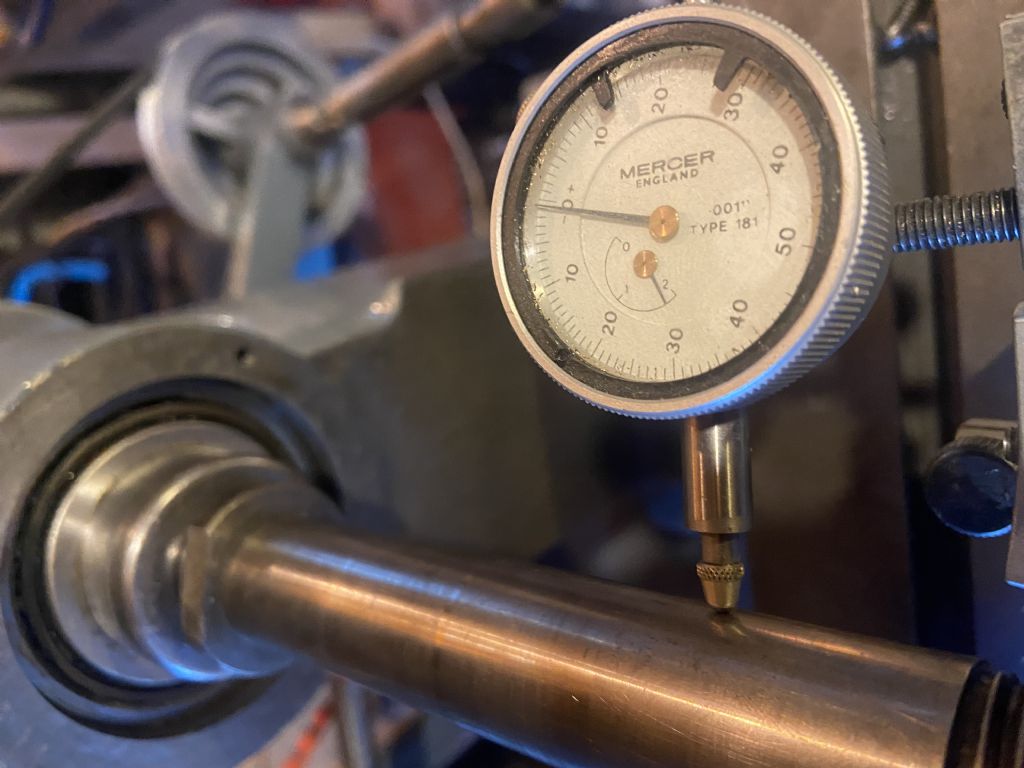

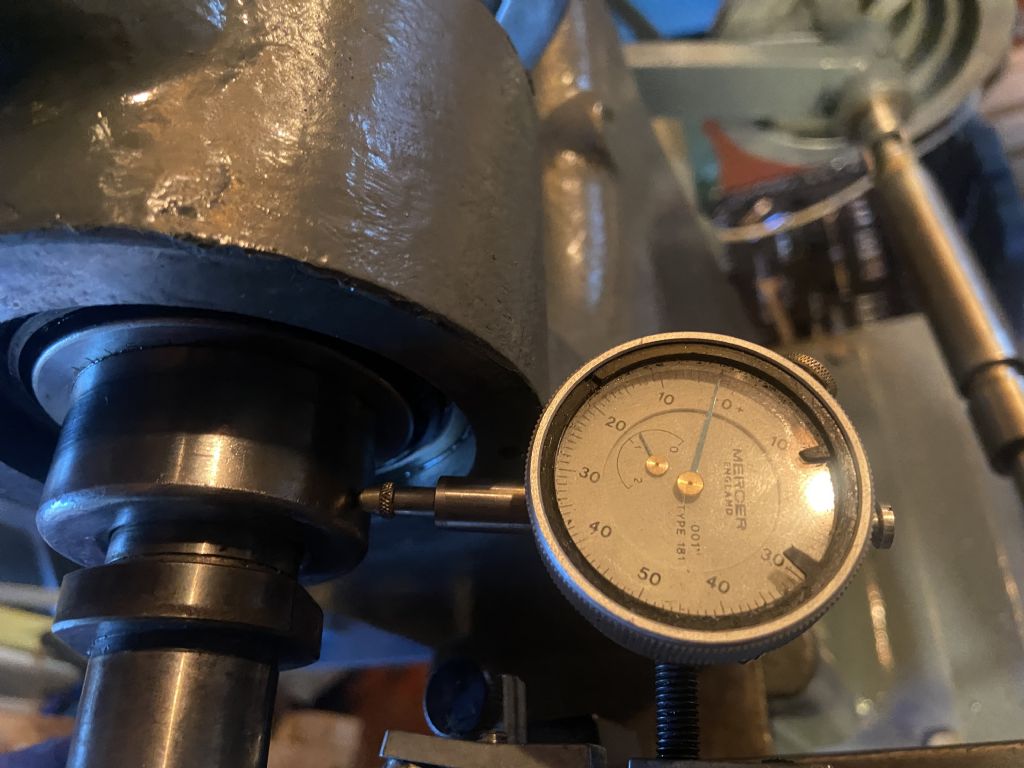

Putting the dial indicator on the spindle I get 0.001 runout.

on the flange (?) of the spindle, I actually get more runout, about 0.00175

But interestingly, on the spindle near the *rear* bearing I seem to get no perceptible runout…

All this seems to indicate that the front bearing isn’t quite seated correctly, or is not adjusted / malfunctioning.

I suppose the spindle could be bent.

I didn’t manage to get the front bearing off when cleaning up the parts. It was well and truly stuck on the spindle and I didn’t want to bash it and risk damaging it. I don’t really know how to remove it.

Spindle out and reseat the front bearing?

I have read Ketan’s advice on preload and heating, that was interesting but I wasn’t sure it was directly relevant to this.

Thanks

Steve

Steve355.

But I will have a think about it, as you say there may be an back gear type solution.

But I will have a think about it, as you say there may be an back gear type solution.