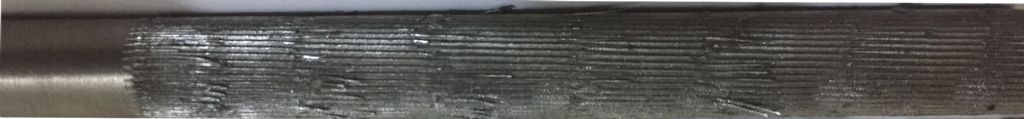

Thanks for replies. One of the ideas I had was that I was going too deep, and as that was reinforced by JasonB's and Tony's comments I had a go with a lighter cut and two passes:

That was going right (tailstock) to left for the first pass, then cranking a quarter turn on the tool before reversing power feed and running back.

Still a long way to go, but a definite improvement.

Another thing I had thought about was the use of flood coolant, which has also been mentioned in comments. Although 'pressure' knurling is regarded a a deformation process, that's clearly not the whole story as significant amounts of swarf are produced. I'm sure that trapped swarf is responsible for some of the deficiencies in the knurl pictured above. Not only does it cause scarring, but I suspect it builds up and deflect the wheel as as well. Flood coolant is the next thing I shall try.

On speeds/feeds, the reason I go so slowly (65 rpm) is that someone somewhere once told me that it was good to go slow and feed hard so that the pattern was well enough established on the first turn of the work to force the wheel to track. My belief (at the moment!) is that the established pattern on the work dominates the 'natural pitch' of the wheel, so the wheel slips to accommodate. But maybe that's wrong? Certainly it seems folk here are going a lot faster and getting good results.

Emgee – the wheels have only a very slight bevel. That's something I could change and shall bear in mind – thank you for pointing that out.

MichaelG – can you unpack your logic (or unpick your intuitions) about the relative difficulties of making long diamond and straight knurls? My intuition was exactly the opposite to yours – but I have no logic. I did look at the Dorian tools, but £s….

I'm unlikely to get back to this in a practical way before the new year (by which time Santa might possibly have dropped a Marlco kit down the chimney, who knows?) – but I'm not giving up on this.

Hope you all have as good a festive season as possible in the circumstances – stay safe!

Robin.

Hopper.