Hi all

Warning – over enthusiastic novice alert!

Ever since I got my lathe a couple of months ago, it has had a finish issue. I presumed that it was my lack of experience, and I tried lots of cutting bits, different speeds and feeds, modifying the cutting point on lathe cutting bit et cetera. But nothing really made any difference. When I got the lathe, it was bolted to a piece of plywood, so I presumed that vibration was the issue, and I got hold of a proper stand, beefed it up with a piece of 6 mm steel plate as a table, and installed the lathe on it.

I then went through the process of adjusting all of the gibs, aligning everything, measuring the different run out, aligning the tailstock et cetera.

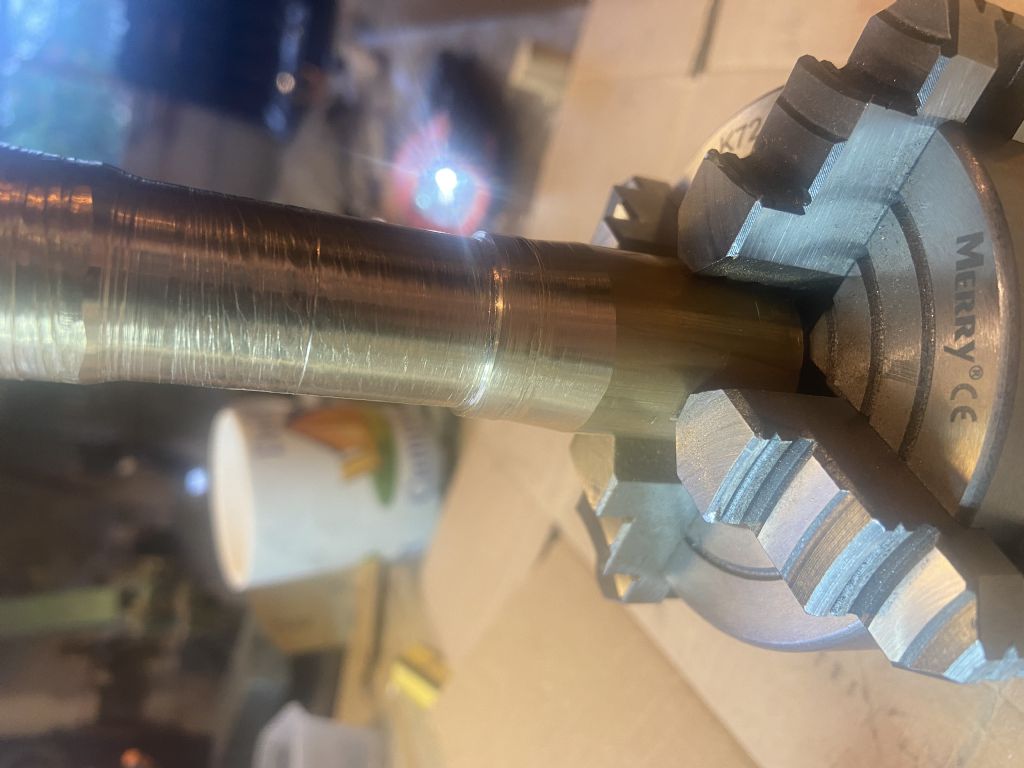

Same problem, worse in fact. See pic.

That was supported by the tailstock.

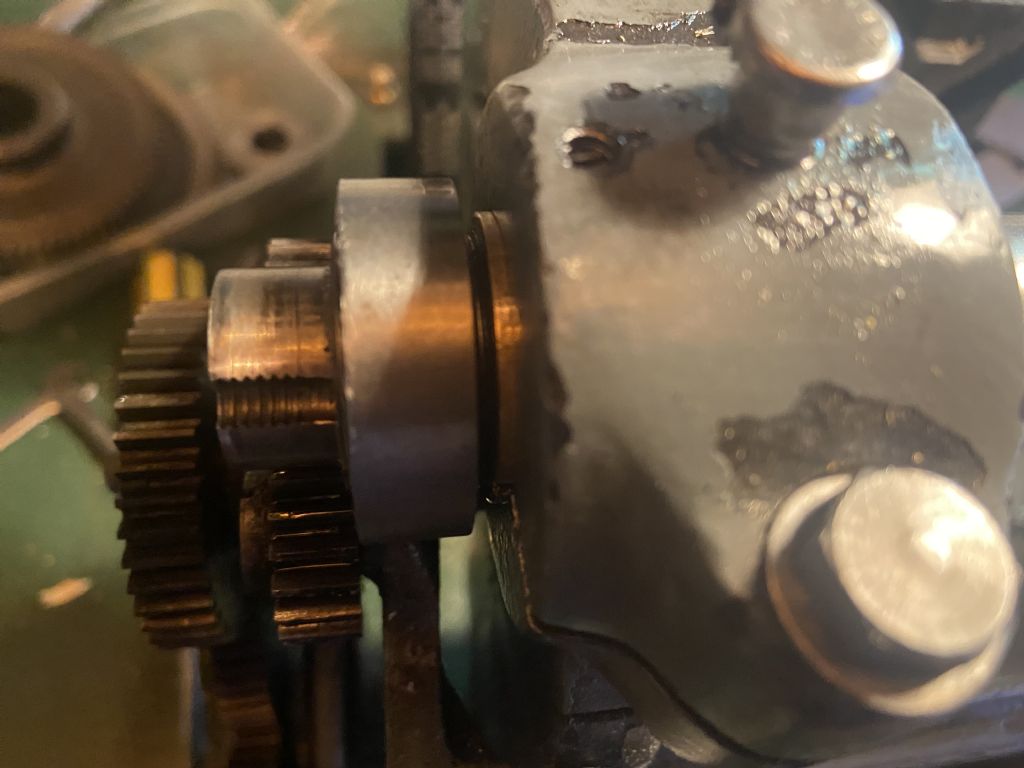

I had it to bits to change the V-belt, so I’m now familiar with the main spindle and the associated parts. Once the main spindle was reinstalled, there is no perceptible lateral movement, and the dial indicator does not measure any runout. However, I did discover that there is about 0.5 mm of longitudinal play. It seemed to me that that could easily be the culprit, and should be resolved anyway. The funny thing was, when I did some facing cuts, there did not seem to be any finish problem.

The race bearing (?) all seems fine. The bearing that the spindle sits in are lined with a brass sleeve, with a hole for oil and an indent for a grub screw to stop them moving about, and then obviously a bolt to set the overall tension. When running, I’ve managed to adjust it so that’s the brass sleeves do not rotate with the spindle, and the overall temperature of the bearing area is “slightly warm“ after running for 10 minutes or so.

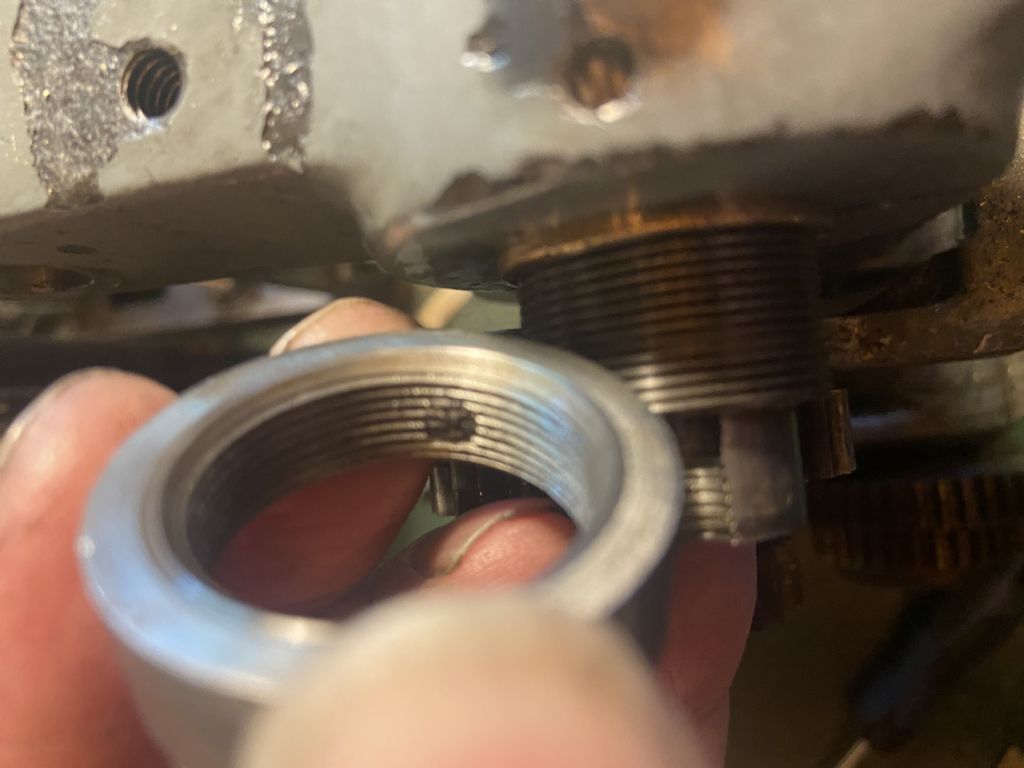

on the far end of the spindle, there is is thread and a collar which screws onto it. This seems to be the way the longitudinal play is controlled. It is secured by a grub screw (which doesn’t seem to go all the way through ?!). But if I screw it up tight enough to eliminate longitudinal play, the spindle will not turn.

And it doesn’t look as though that collar is designed to run against the face of the second bearing (which is painted). So I’m not really sure how to secure the longitudinal travel of the spindle correctly.

questions…

Am I barking up roughly the right tree? Or is it like to be a different problem?

Am I doing this correctly?

How to fix the longitudinal travel issue?

cheers

Steve

Russell Eberhardt.

Russell Eberhardt.