This doesn't seem to be a problem for me, but I came across discussions of the influence of lathe tailstock height misalignment on turning parallel between centres whilst looking for other related info. The discussions were initiated by people who had bought a lathe and, by one method or another, had found the tailstock centre to be high with respect to the headstock. The advice from seasoned hands was not to worry – provided the tailstock is OK in the horizontal plane, vertical alignment (unless grossly out) would be insignificant, but no explanation was given. I wanted to understand this better and tried to work it out.

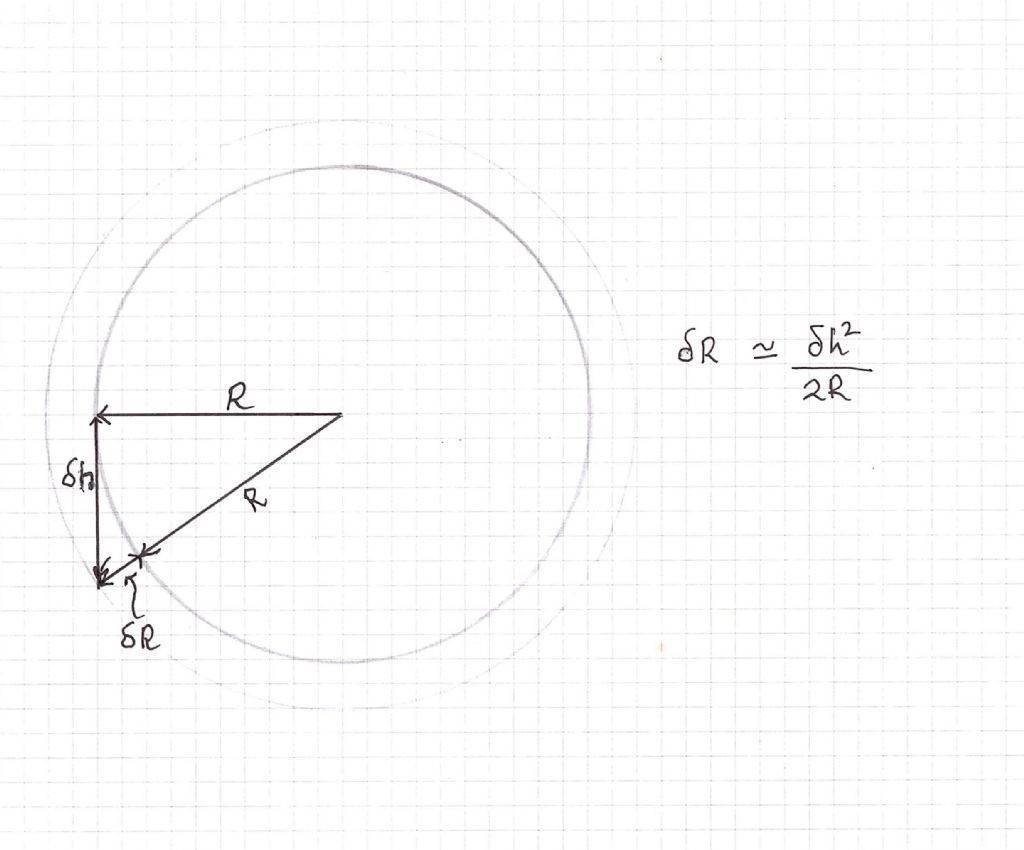

I'm very bad at 3-D visualisation so tried to approximate the problem by imagining that the tool was cutting dead on centre at the headstock and low by delta_h at the tailstock:

After a bit of algebra it came out that the radius at the tailstock end would be the radius at the headstock plus the square of the distance of the tool under centre at the tailstock divided by the diameter of the work at the headstock.

If this is so, it would explain to me why vertical alignment is relatively unimportant – on a nominal 10mm diameter workpiece, even if the tailstock were 0.1mm high it would lead to a discrepancy of 0.1×0.1/10 = 0.001mm on radius.

I'm not sure that I've set the problem up correctly though – I've a sneaky feeling that I've over simplified, and conic sections or something come into it. The intersection of a plane with a cylinder can be an ellipse, so maybe turning with the tailstock off-height gives a barrel shape – I just can't visualise it!

I realise that this may have little practical importance at home workshop levels of accuracy, but I'd like to understand it better.

Robin

Martin Connelly.

Martin Connelly.