I'd be very wary of connecting a "£50 RS controller" to any machine-tool unless it is genuinely compatible with the motor – by type as well as voltage and power values.

The sort of 1-3ph inverters you seen often mentioned on this forum slow the speed of a synchronous motor by reducing the frequency, while keeping most of the Watts up. Does that from RS work in the same way for a 1ph motor, or is it simply an amplitude-chopper that slows the motor by reducing the power? If the latter, it would be useless for controlling a machine-tool like a steel-cutting band-saw.

Also, it's not good to run a motor very slowly for long, if only for cooling; and on any machine-tool it is cutting speed, not the motor speed, that has to be lowered with minimum power-loss between motor and work. I can run my Harrison lathe at about 70rpm – but using the gears to keep its 3ph motor happy at around 1000rpm.

'

Don't be misled by work-speed alone. You need consider the feed as well – dictated by the amount of material each tooth can shave off. That a material can be cut at high speeds does not mean it has to be, but many materials can only be cut at very low speeds, on the sort of machines we generally encounter anyway.

A saw made primarily for cutting wood may cut fairly thin aluminium plate with an appropriate blade – not the wood-sawing blade – moderately well, but is far too fast for steel.

A saw made primarily for cutting metals including thick steel will cut wood, with a suitable blade, without problems. It just take longer because the blade speed is low.

In both cases each tooth should be removing its fair share of metal or wood, but at a lower speed just takes a bit longer to do so. Not on piece-rates are you?

.

Conventional vertical band-saws do not have vices so are not suitable for cutting steel bar-stock, although some have geared or belt transmissions allowing low enough speeds for steel. Also, the throat depth obviously limits the maximum length handled.

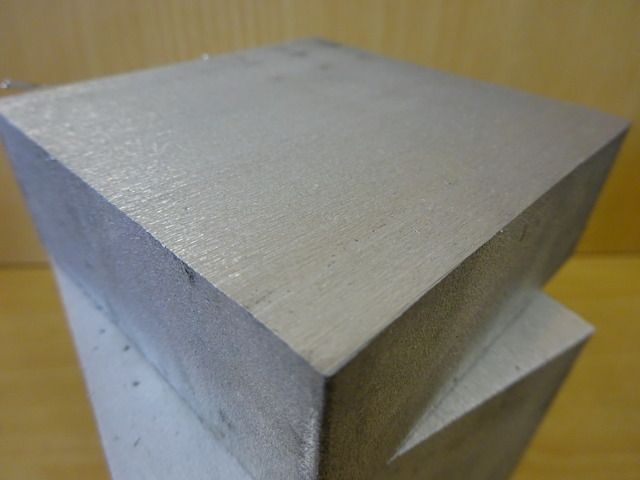

I used at work, a Startrite band-saw that could cut 2ft X 2 ft squares of 1/4" gauge-plate – hand-fed, very slowly and tediously, at its lowest speed – but it was a machine made for metals-cutting; and I had the range of blades necessary for the work I did on it.

Conventional horizontal band-saws for cutting metals have a vice, and though limited on height and width do not impose length limits. They will also cut wood, though preferably with a wood- cutting blade, coarser and with wider set. A fine blade suitable for solid steel will clog on most woods.

The common dual horizontal / vertical band-saws sold under a number of badge-brands are versatile but tend to suffer from two drawbacks. The tables supplied are small and not well-supported, and the upper blade-guide cannot be lowered closely to the work. These do not help accurate work. Nevertheless they are useful provided you realise their limitations.

(The " pressed-tin" stand supplied with some of those leaves much to be desired, as well. Like many users, I treated mine to a strong trolley on heavy-duty castors.)

SO….

If you need cut metals even if mainly cutting wood, but have room only for one "universal" machine, you are better off with one of those vertical/horizontal machines that can cut the relatively hefty steel sections. Their lowest speeds are optimised for mild-steel, with an appropriate blade (typically 14tpi), but will run fast enough for wood, although a coarser blade is better for that.

Howard Lewis.