Thanks to all of you for the encouraging and helpful messages with plenty of useful information. It's still very much a thought experiment for me.

I think I would be able to produce a camshaft using the turning jig method, without needing a rotary table, milling machine or a grinder. It is reassuring to see that a decent sized paper disc marked out in degrees is good enough to be practical, though I am surprised that the one inch disc with marker pen lines, shown in the video clip from Andy G. would be precise enough. Some kind of pointer has to be registered to the shaft, to operate this system. The complicated method used by Graham Meek in the link from Diogenes, or that used by Charles Lamont, would be too much too much trouble for me.

I understand Jason's point on making the cams in pairs, on the turning jig, which I could case harden, and polish, then mount on the unhardened shaft, though I would need to devise a method to set the angular positions of the pairs relative to each other and to the shaft keyway. With all four cams made together this would be taken care of. The pairs would have to be drilled through after making, then the excess shaft length cut off, before hardening.

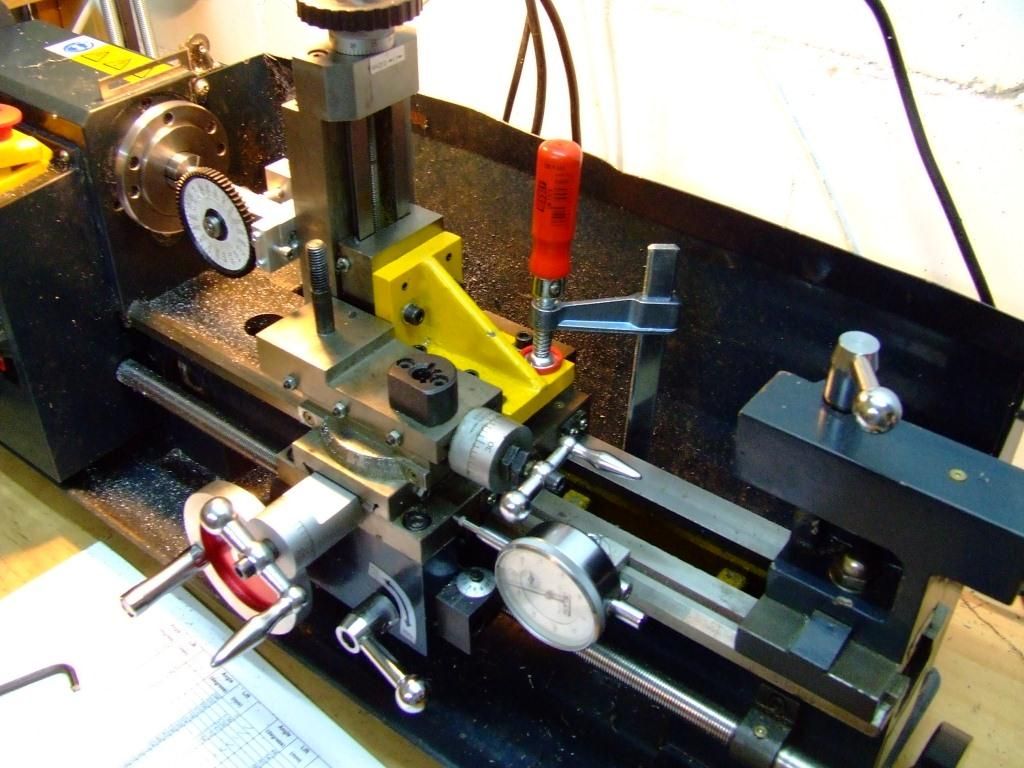

I could use milling in the vertical slide as shown by Roger B, though this would need a reducing sleeve with two keyways to register the change wheel to the shaft, and 60 teeth would not enable the 130 degree setting for the exhaust cam flanks. But, in principle I could do it.

So each method has its pros and cons, with balances of time, effort and precision to be decided.

I understand the point about the fit of piston to bore, it has to be much closer than in a steam engine. This is one reason why a diesel engine would not be my choice because this fit has to be even closer than for a four stroke. And not only do I need a close fit, but it has to be dimensionally accurate, to use piston rings as provided in the kit.

My aim would be to produce an engine which could run on a table top setup, and, importantly for me, would drive a load which could be regulated. No ideas yet on what would be practical for that. Thinking is a lot easier and quicker than doing!

Paul

Roger B.

)

)