If the problem is clearly defined, the means of solving it will be more easily found..

For those fortunate enough to have been in Engineering all their lives, this becomes second nature, but for a newbie this has to be part of the learning curve.

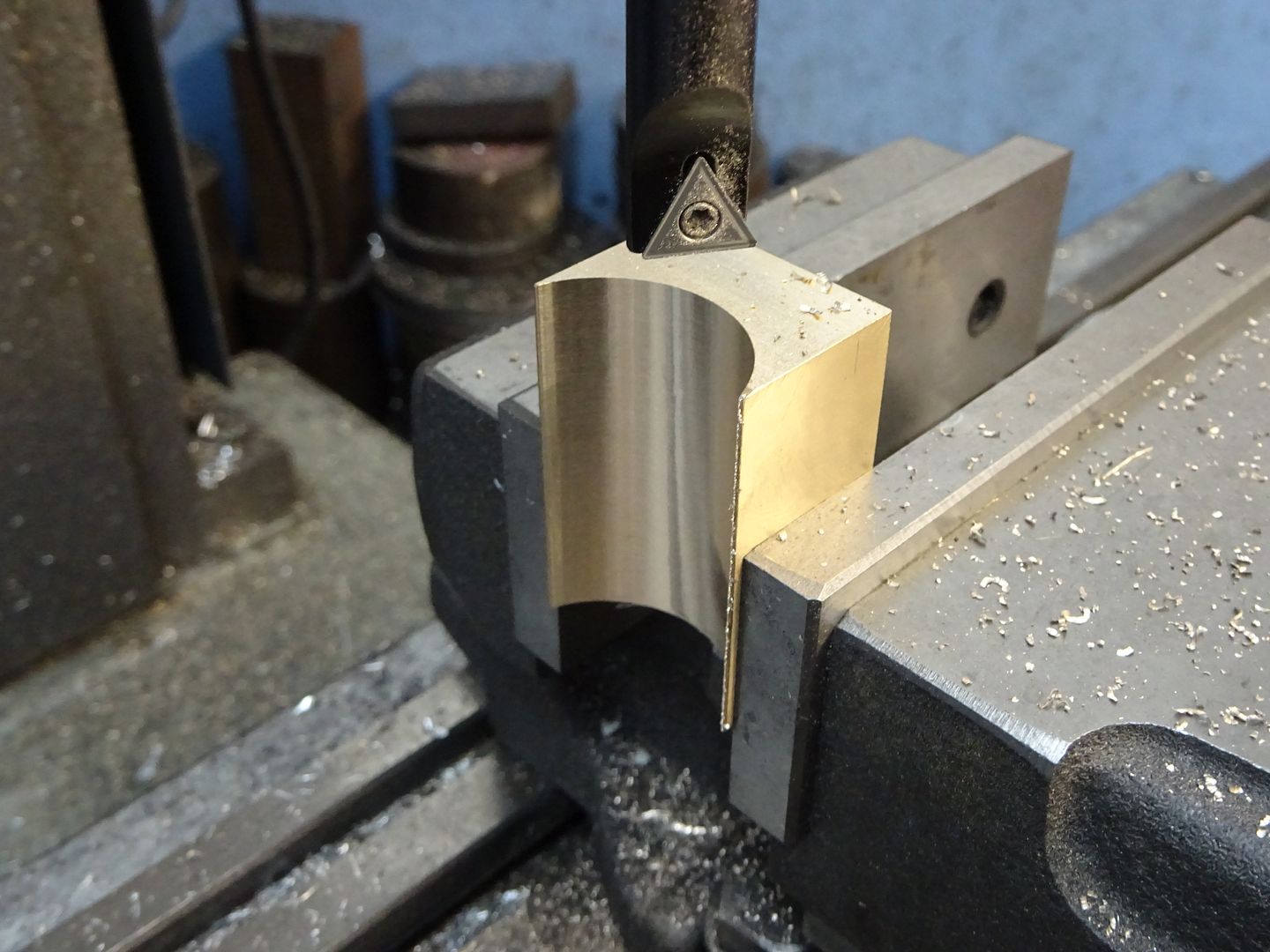

Naming a process or part incorrectly can cause confusion and produce answers to a question that has not been asked. A picture or drawing often clarifies matters.

So it is beginning to sound like a groove 1.25 mm deep across the face with a 2.5 mm ball nose end mill.

Personally, I would be wary of doing it all in one cut, half the diameter of the end mill, even with a very fine feed.

(Unless you have LOTS of spare cutters to hand! )

Maybe gradually take out out some of the material with a 2mm end mill, for part of the depth, and then finish off with the ball end cutter.

Howard

Howard Lewis.