Thanks for the comments Paul and Dom. I'll try and sort the CAD model out tomorrow and have a look.

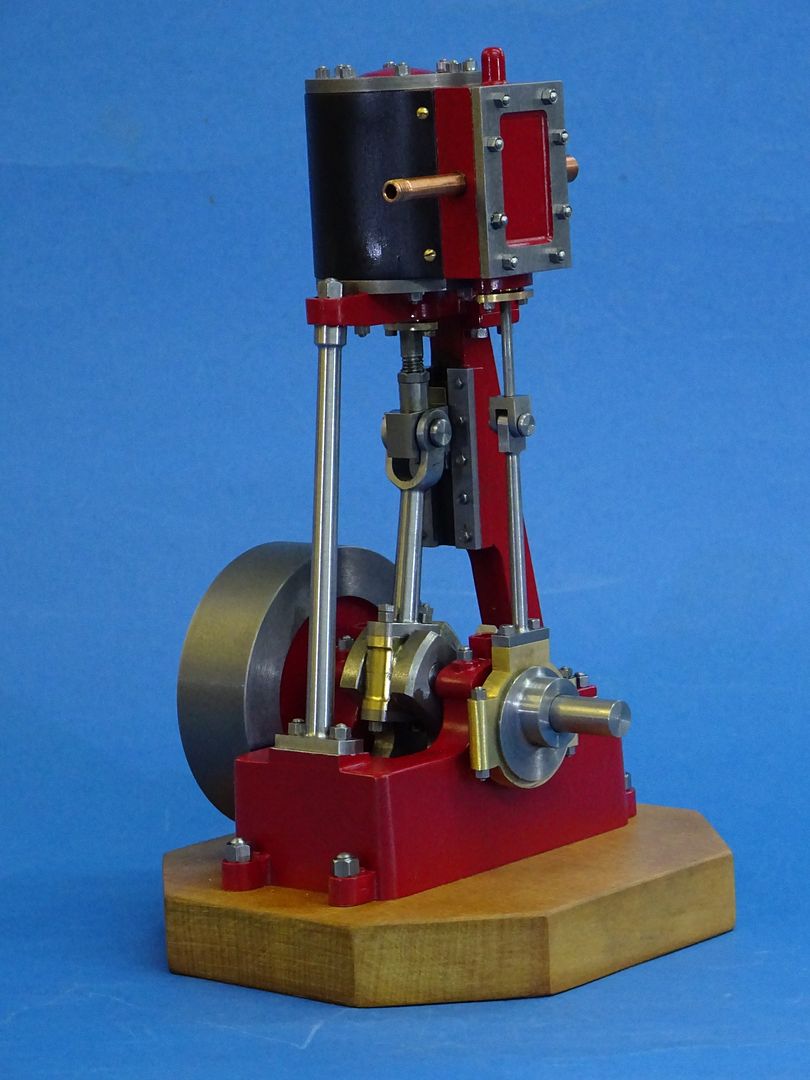

Stuart models are indeed very nice, and I will probably end up with the Twin Victoria, simply because I've always liked it, and so far nobody has said "this is equivalent, but better/cheaper". I did have a look at the alternatives proposed on this thread. One thing about Stuart models that makes me pause, is the cost. Is it just an "expensive" brand in the grand scheme of things, or is it average? I have no issue at all with the quality of the 10V, but the price of spare parts seemed pretty steep; things like bar stock rather than castings. Also, I noticed the other day that a "ready to run" 10V will set you back over £800…really??

Going back to the 1" Minnie traction engine. I think that's the one for me: it looks spot-on, plenty of support from people who've been there and done it as well. So yes, that's what I'm going to progress with in terms of my long-term project. I'll start by getting the build book off Amazon or EBay when one comes up a reasonable price. A few specific questions:

1) Where are the best "start to finish" build threads on here, or on other websites?

2) I was considering buying individual castings and parts as and when I could afford them – assuming I'd be building another smaller model in the meantime. What is the best way of getting parts – buy a complete set from somewhere, or buy individual items?

3) The boiler. Thinking about Dom's comment about building a boiler: I was under the impression that this was a very tricky thing to get right, with obvious safety implications if it's not. I want to know – 100% – that the boiler is safe. I'm not at all sure about building one. What's the best way forward? Buy a certified boiler for that model (if they're available)? Try to make one and have it proof tested? No idea.

Any advice is, as always, much appreciated. Thanks.

Dr_GMJN.