Hi Andrew, you will always be faced with such problems when it comes to cutting small pieces off of small pieces, and you very often have to find a way to deal with it. Slitting saw arbors are what they are and have to be strong enough to give enough friction to hold the saw. I machined a small piece a while ago, which then had to be cut off and was faced with the same problem.

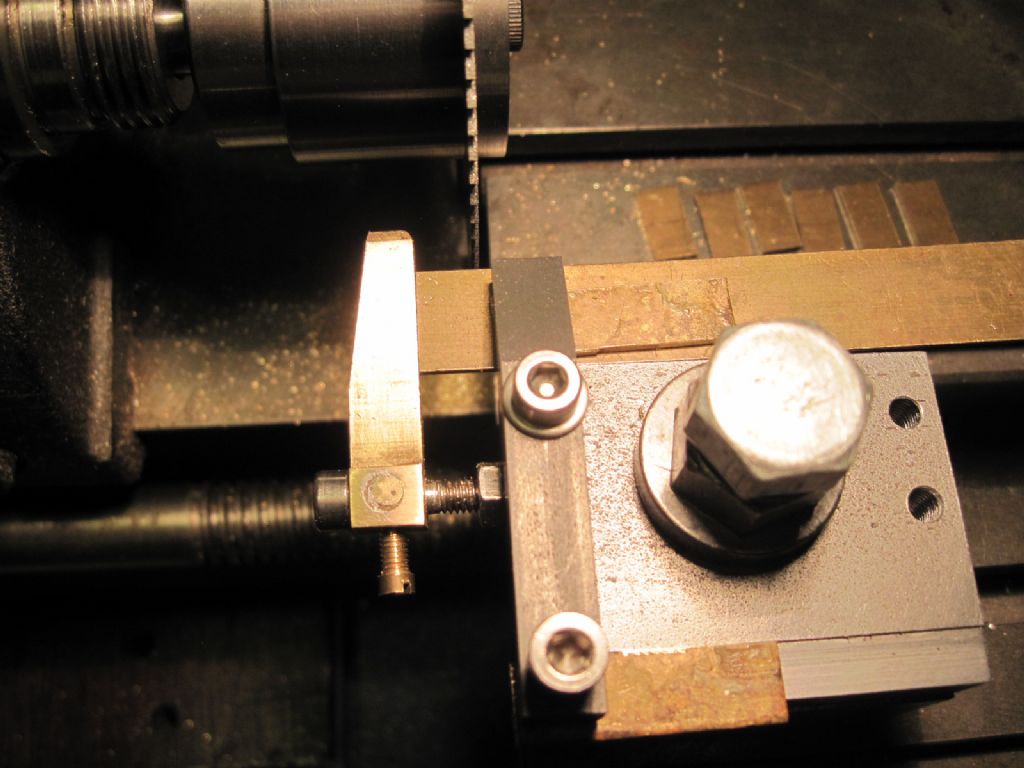

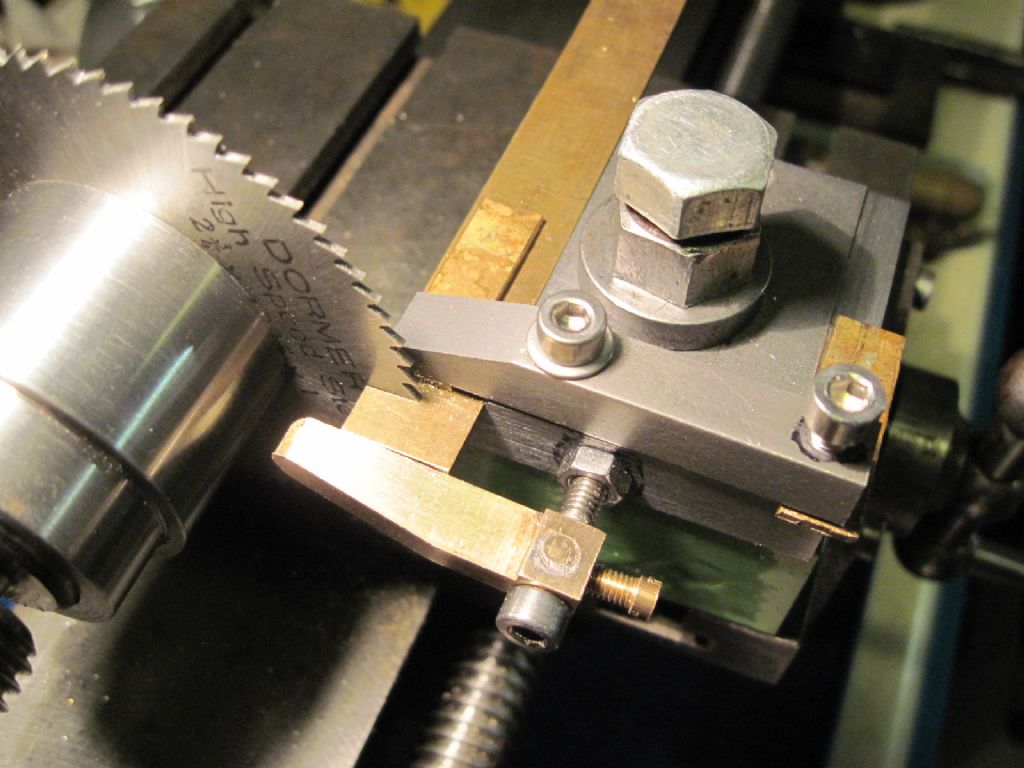

OK, the threaded holes were part of the end result of two bespoke nuts, but needed to be sawn off the piece in the vice, but this was not long enough to raise up in the vice to allow the slitting saw and arbor to be used, so my solution without trying to hold it in a bench vice and trying to hacksaw it off neatly, is shown below.

It was sawn halfway through one side and finished on the side shown above and was just cleaned up lightly with an end mill. It was held onto the block with a couple lengths of threaded rod in the holes and just raised in the vice with two small blocks to keep it level and to accommodate the nuts on the threaded rod at the bottom. Always best to plan ahead when doing fiddley jobs like this, like how to hold it and get into cut or mill and can you utilise holes in the part itself, to do subsequent operations, do a dry run if needed as it is frustrating to find you can't finish the way you prefer.

Regards Nick.

Michael Gilligan.

Michael Gilligan.